User's Manual

Table Of Contents

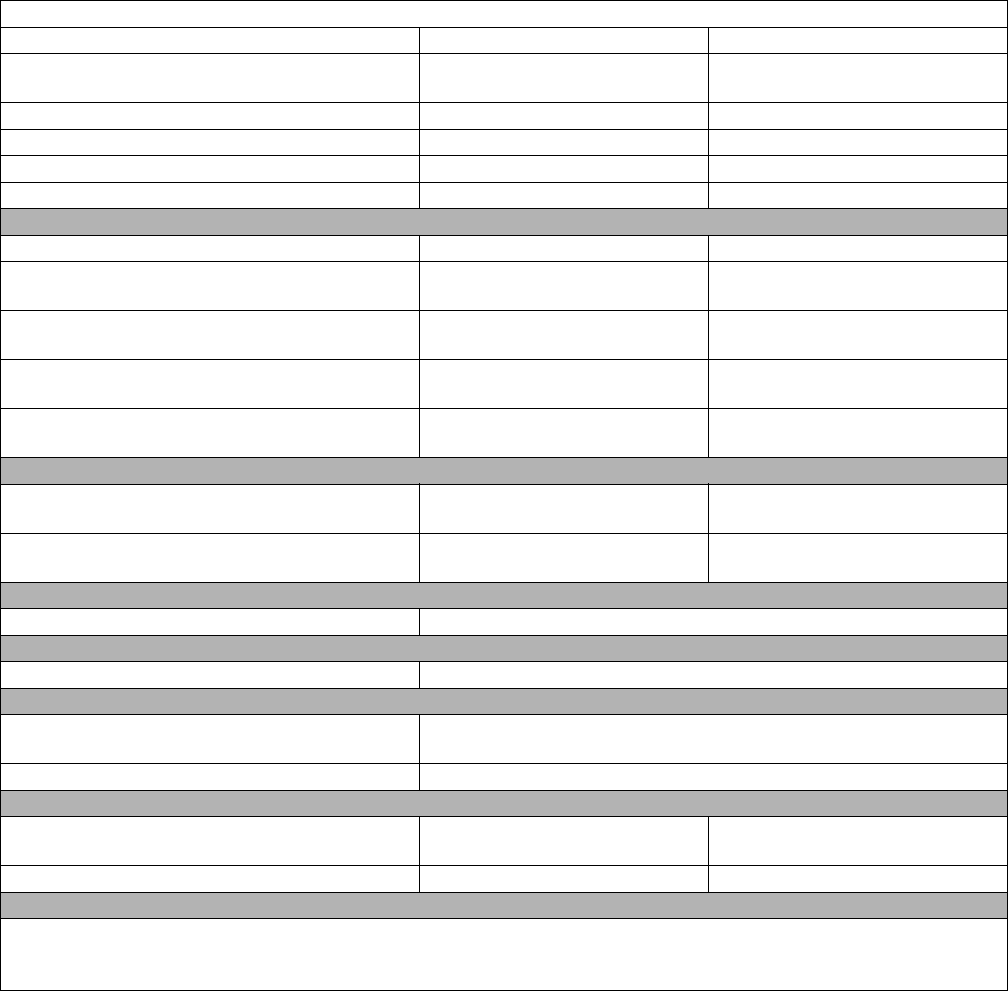

Technical Data

124 333347F

Main System Air Supply Pressure Range (set with

regulator on front of system)

80-100 psi 0.55-0.69 MPa (5.5-7 bar)

Pump Operating Air Pressure Range 20-100 psi 0.14-0.69 MPa (0.7-7 bar)

Pump Operating Fluid Pressure Range 240-1200 psi 1.7-8 MPa (17-80 bar)

Control Temperature Range 100-400°F 38-204°C

Ambient Temperature Range 32-120°F 0-49°C

Vacuum Transfer Specifications

Maximum Vacuum Transfer Hose Length 30 ft 9.1 m

Maximum Vacuum Transfer Hose Maximum Verti-

cal Rise

10 ft 3.0 m

Vacuum Transfer Operating Pneumatic Pressure

Range (set with regulator on front of system)

40-100 psi 280-690 kPa (2.8-6.9 bar)

Vacuum Transfer Air Consumption at 40 psi (280

kPa, 2.8 bar),

9.5 scfm (intermittent duty; 4% at

25 lb/hr)

16.1 scmh (intermittent duty; 4% at

11.3 kg/hr)

Vacuum Transfer Air Consumption at 80 psi (550

kPa, 5.5 bar)

17.2 scfm (intermittent duty; 4% at

25 lb/hr)

29.2 scmh (intermittent duty; 4% at

11.3 kg/hr)

Required Air Tubing Size

Minimum Air Tubing Inner Diameter (less than 50

ft, 15.2 m of tubing)

3/8 in. 9.5 mm

Minimum Air Tubing Inner Diameter (50 ft, 15.2 m

or longer of tubing)

1/2 in. 12.7 mm

Sound

Sound Pressure Level*** 77 dB(A)

IP Code

InvisiPac Base System IP54

Wetted Parts

Wetted Parts PTFE, chemically resistant o-rings, aluminum, stainless steel, zinc plat-

ing, carbon steel, brass, carbide, chrome

Approvals and Standards UL499, CSA88, CE, ISO

30 Gallon Vibrating Hopper

Required Air Pressure Supplied To 30 Gallon

Vibrating Hopper

100 psi 0.7 MPa (7 bar)

Air Consumption 17.1 scfm 29.1 cubic meters per hour

* From 70°F to 350°F (21°C to 177°C), dependant upon power supply and machine configuration.

** Excludes vacuum transfer tube, shaker assembly, and pellet storage bin.

*** Sound pressure level measured 3.1 ft (1 meter) from equipment.

InvisiPac Hot Melt Delivery System

US Metric