User's Manual

16 308345

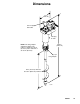

Parts Drawing

TI0301B

1

3

4

2

1

5

3

18

16 or 17

26

27

1

12

12a

22

5

6

41

24

25

24

25

4

8

7

46

50

44

20

45

21

11

11

9

32

34

33

2

10

13

14

15

14a

35

28

29

31

30

2

3

4

6

7

8

10

6

8

7

10

See Detail

39

27

30

11

11

56

11

12

12

9

9

Includes items 18a to 18e

18a

18c

18e

18d

18b

51

Needle Valve (Ref. No. 18) Detail

16a

Press into place; lips face down.

Apply high-strength thread sealant

to threads.

Apply anaerobic PTFE pipe sealant

to threads.

With helix tube (7) flush with top of

bushing (14), torque oppositely and

evenly to 55 to 60 in-lbs (6.2 to 6.8

Nm).

Tighten after you align pulleys

(12 and 13). Torque setscrew to

45 to 55 in–lbs (5.1 to 6.2 Nm).

Drive belt must not be tight after it is

installed.

Bend washer tab up to lock.

Apply PTFE spray lubricant to

inside lip of bearing nut before you

install it.

Torque oppositely and evenly to 80

to 100 in-lbs (9 to 11.3 Nm).

Torque oppositely and evenly to 60 to

70 in-lbs (6.8 to 7.9 Nm).

Apply PTFE spray lubricant to siphon

tube (4) inlet end and to top 6 in.

(150 mm) of helix tube (7) before you

install them.

Install flush with top of nut (8), and

torque to 40 to 45 in-lb (4.5 to 5.1

Nm).

5

Install with outer lips facing up. See

Fig. 8 on page 12.

13

13

3

3

3

3

3

51

3

0911B

18f