Installation Guide

Table Of Contents

- Installation Guidelines 60 Hz Air-Cooled Generators

- Table of Contents

- Section 1: Safety Rules & General Information

- Section 2: Unpacking and Inspection

- Section 3: Site Selection and Preparation

- Section 4: Generator Placement

- Section 5: Fuel Conversion / Gas Connections

- Section 6: Electrical Connections

- Section 7: Control Panel Startup / Testing

- Section 8: Troubleshooting

- Section 9: Quick Reference Guide

- Section 10: Accessories

- Section 11: Diagrams

Fuel Conversion / Gas Connections

Installation Guidelines for 60 Hz Air-Cooled Generators 25

Checking Fuel Line Connections

Checking Fuel Pressure

Proceed as follows to check fuel pressure at fuel regula-

tor in the generator.

1. Close fuel supply valve.

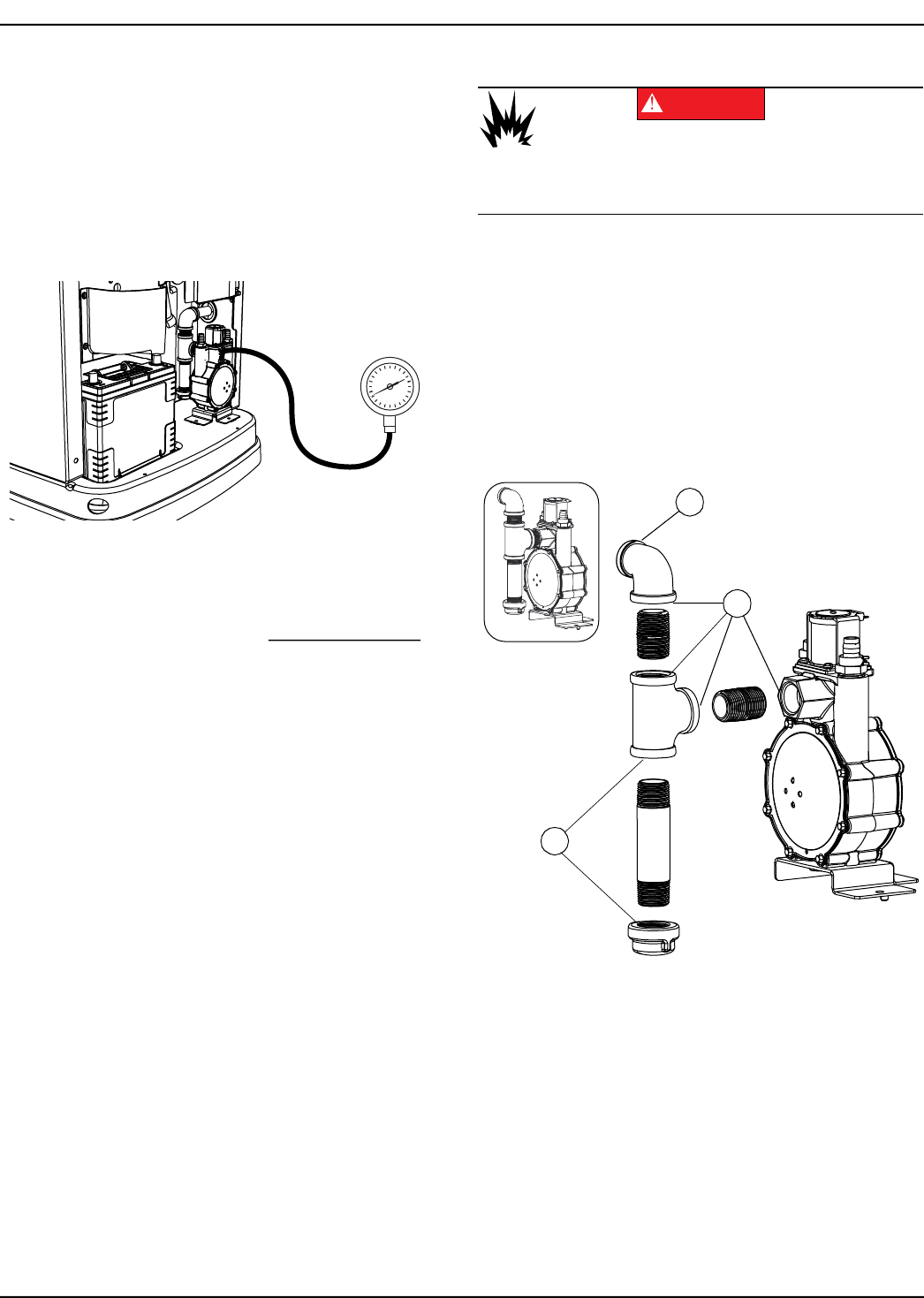

2. See Figure 5-4. Remove top fuel pressure test port

from fuel regulator and install fuel pressure tester

(manometer).

Figure 5-4. Checking Pressure with Manometer

3. Open fuel supply valve and verify fuel pressure is

within specified values.

4. Record static fuel pressure:

NOTE: Fuel pressure can also be tested at manometer

port on fuel shutoff valve shown in Figure 5-2.

NOTE: See fuel data decal or spec sheet for correct fuel

pressure specifications. Contact local fuel supplier if fuel

pressure is not within specifications.

5. Close fuel supply valve when completed. Keep

manometer connected for future tests of generator

while starting, running, and under loads.

Performing Fuel System Leak Test

All products are factory-tested before shipping to verify

the performance and integrity of the fuel system. How-

ever, it is important to perform a final fuel system leak test

before starting the generator. The entire fuel system

should be tested from supply to regulator.

See Figure 5-5. Perform a final fuel system leak test

after generator installation. The test will identify possible

leaks at all connection points (A).

It is best practice to perform a fuel system leak test

during normally-scheduled maintenance.

Figure 5-5. Connection Points to Leak Check

Inspect for leaks by spraying all connection points with a

non-corrosive gas leak detection fluid. The solution

should not be blown away or form bubbles.

001807

(000192)

DANGER

Explosion and fire. Fuel and vapors are extremely

flammable and explosive. No leakage of fuel is

permitted. Keep fire and spark away. Failure to do

so will result in death or serious injury.

A

A

A

004038