Installation Guide

Table Of Contents

- Installation Guidelines 60 Hz Air-Cooled Generators

- Table of Contents

- Section 1: Safety Rules & General Information

- Section 2: Unpacking and Inspection

- Section 3: Site Selection and Preparation

- Section 4: Generator Placement

- Section 5: Fuel Conversion / Gas Connections

- Section 6: Electrical Connections

- Section 7: Control Panel Startup / Testing

- Section 8: Troubleshooting

- Section 9: Quick Reference Guide

- Section 10: Accessories

- Section 11: Diagrams

Fuel Conversion / Gas Connections

Installation Guidelines for 60 Hz Air-Cooled Generators 23

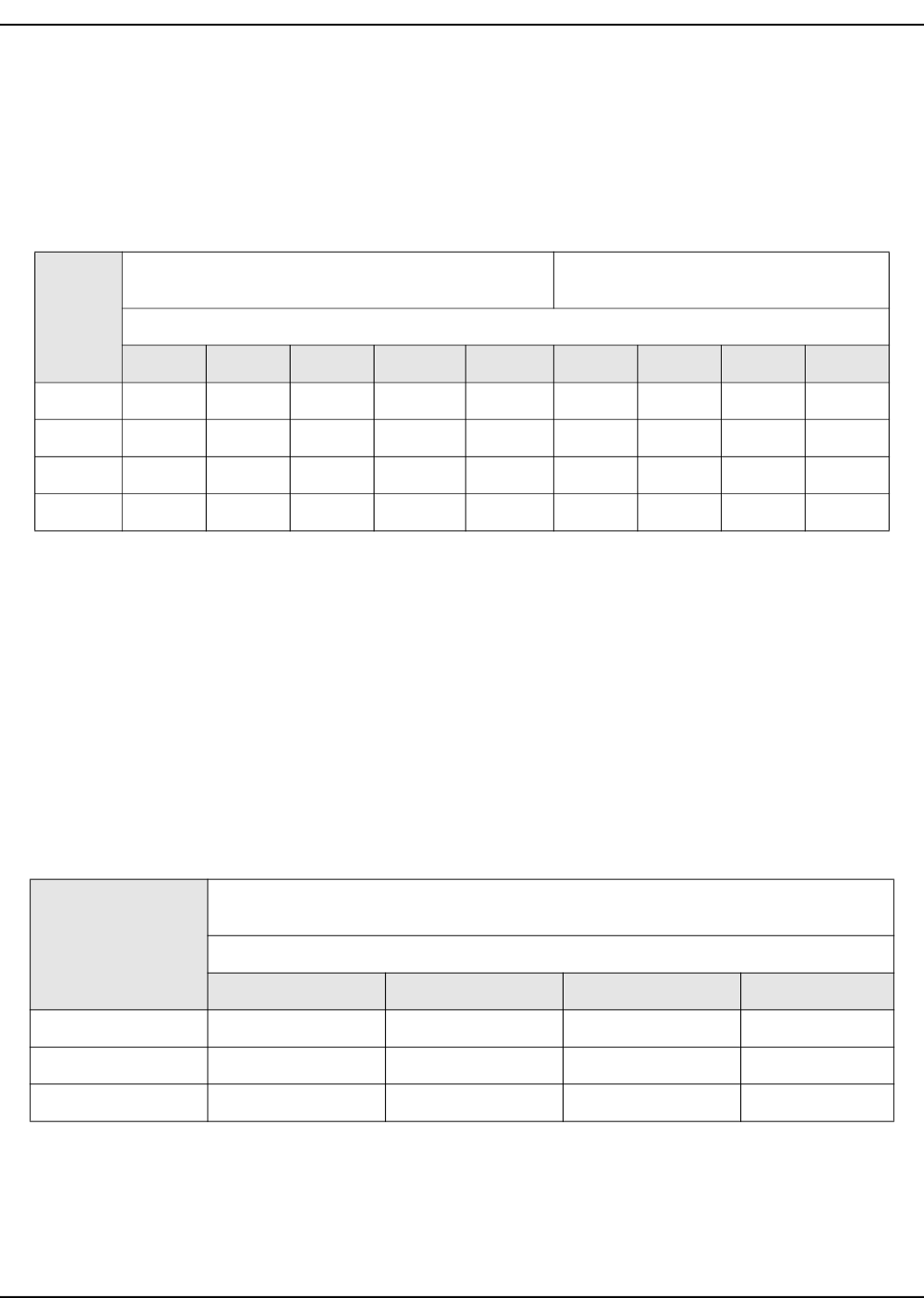

Natural Gas Pipe Sizing

To determine correct NG pipe size, find the kW rating of

generator in the left column, and trace to the right. The

number to the right is maximum length (measured in ft /

m) allowed for the pipe sizes on top. Pipe sizes are mea-

sured by trade size diameter to include any fittings,

valves (must be full flow), elbows, tees, or angles.

NOTE: See Table B.3.2 in NFPA 54 or Table A.2.2 in the

ICC IFGC, Equivalent Lengths of Pipe Fittings and

Valves for the correct values to be added to overall fuel

piping length. Tables are based on schedule 40 black

pipe. If installing any other piping system, follow pipe siz-

ing charts for selected piping system.

LP Gas Pipe Sizing

To determine correct LP gas pipe size, find the kW rating

of generator in the left column, and trace to the right. The

number to the right is maximum length (measured in ft /

m) allowed for pipe sizes on top. Pipe sizes are mea-

sured by trade size diameter to include any fittings,

valves (must be full flow), elbows, tees, or angles. See

Table B.3.2 in NFPA 54 or Table A.2.2 in the ICC IFGC,

Equivalent Lengths of Pipe Fittings and Valves for the

correct values to be added to overall fuel piping length.

NOTE: Pipe sizes are from the outlet of the second

stage regulator to the fuel shutoff valve. Table is based

on schedule 40 black pipe. If installing any other piping

system, follow the pipe size charts for the selected piping

system.

NOTE: Recommended minimum LP tank size is 250 gal

(946 L). Contact LP provider to correctly size LP tank to

generator. Vertical tanks, which are measured in pounds

(or kilograms), are permitted if correctly sized for the gen-

erator. Do not connect generator to a 20 or 30 lbs LP

tank.

Table 5-1. NG Pipe Sizing

Pipe Size

(in / mm)

For 5–7 in Water Column

(1.24–1.74 kPa)

For 3.5–5 in Water Column

(0.87–1.24 kPa)

Allowable Pipe Distances (ft / m)

0.5 / 13 0.75 / 19 1 / 25 1.25 / 32 1.5 / 38 0.75 / 19 1 / 25 1.25 / 32 1.5 / 38

10 kW 10 / 3.1 60 / 18.3 200 / 61 750 / 228.6 — 20 / 6.1 60 / 18.3 175 / 53.3 —

14/18 kW — 10 / 3.1 55 / 16.7 200 / 60.9 450 / 137.1 — 30 / 9.1 125 / 38.1 200 / 61

20 kW — 10 / 3.1 35 / 10.7 140 / 42.3 300 / 91.4 — 10 / 3.1 60 / 18.3 125 / 38.1

22/24 kW — 10 / 3.1 30 / 9.1 115 / 35.1 250 / 76.2 — 10 / 3.1 60 / 18.3 125 / 38.1

Table 5-2. LP Gas Pipe Sizing

Pipe Size (in / mm)

For 10–12 in Water Column

(2.49–2.99 kPa)

Allowable Pipe Distances (ft / m)

0.5 / 13 0.75 / 19 1 / 25 1.25 / 32

10 kW 30 / 9.1 175 / 53.3 400 / 121.9 —

14/18 kW — 80 / 24.4 350 / 106.7 600 / 182.9

20/22/24 kW — 40 / 12.2 175 / 53.3 550 / 167.6