Recreational Vehicle Generator Diagnostic Repair Manual

Section 7

DIAGNOSTIC TESTS

Figure 7-34. – Cylinder Balance Test

The cylinder balance test will also detect a cylinder

that is not functioning. When grounding out one cylin-

der there will be no RPM loss. When the other cylin-

der is grounded out the engine will stop.

TEST 30 - CHECK SPARK PLUGS

DISCUSSION:

During Test 29, if spark jumped the tester gap, the

ignition system must be functioning properly. However,

if the engine misses the spark plug itself may be

fouled.

PROCEDURE:

Remove spark plugs. Clean with a commercial sol-

vent. DO NOT BLAST CLEAN SPARK PLUGS.

Replace spark plugs if badly fouled, if ceramic is

cracked, or if badly worn or damaged. Set gap to

0.030 inch (0.76mm). Use a NGK BPR6HS (or equiv-

alent) replacement spark plug.

SET PLUG GAP AT 0.030 inch

(0.76 mm)

Figure 7-35 – Setting Spark Plug Gap

RESULTS:

1. Clean and regap or replace sparks plug as neces-

sary.

2. If spark plugs are good for gasoline models, go to

Test 33. For LPG models, go to Test 32.

TEST 31 – CHECK AND ADJUST IGNITION

MAGNETOS

DISCUSSION:

The ignition system used on GT-530 engines is a

solid-state (breakerless) type. The system utilizes a

magnet on the engine flywheel to induce a relatively

low voltage into an ignition magneto assembly. Ignition

magneto internal components increase the voltage

and deliver the resulting high voltage across the spark

plug gap.

The ignition magneto houses a solid state-circuit

board that controls ignition timing. Timing is fixed and

spark advance is automatic.

Major components of the ignition system include (a)

two ignition magneto assemblies, (b) the spark plugs,

(c) the engine control printed circuit board and (d) the

engine flywheel.

Solid-state components encapsulated in the ignition

magneto are not accessible and cannot be serviced. If

the magneto is defective, the entire assembly must be

replaced. The air gap between the magneto and the

flywheel magnet is between 0.012” to 0.015”.

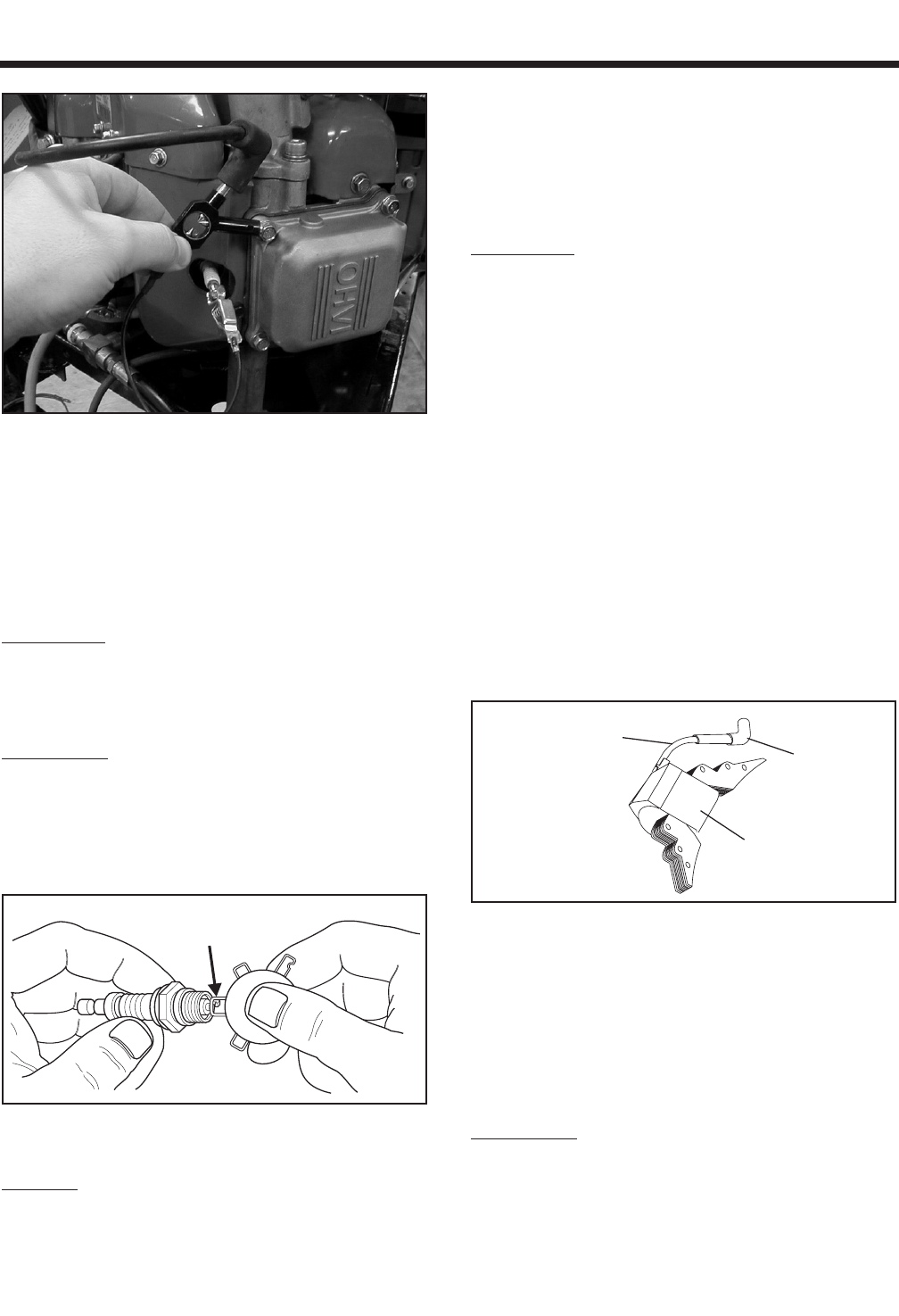

The ignition magneto assembly (Figure 7-36) consists

of (a) ignition magneto, (b) spark plug high tension

lead and (c) spark plug boot.

SPARK PLUG

HIGH TENSION

LEAD

SPARK

PLUG

BOOT

IGNITION COIL

Figure 7-36. – Ignition Magneto Assembly

In Test 29, a spark tester was used to check for

engine ignition. If sparking or weak spark occurred,

one possible cause might be the ignition magneto(s).

This test consists of adjusting the air gap between the

ignition magneto(s) and the flywheel. The flywheel

and flywheel key will also be checked during this test.

If no sparking occurs, the ground harness may be at

fault.

PROCEDURE:

1. Disconnect the J1 connector from the Printed

Circuit Board. Carefully remove Wire 18A from Pin

Location J1-14. Connect the J1 connector back to

the Printed Circuit Board. Repeat Test 29 “Check

Ignition Spark”. If the unit now produces spark go

Page 55