Recreational Vehicle Generator Diagnostic Repair Manual

“Infinity” should be measured. Set the Start-Stop

Switch to “START”. The meter should now read

“Continuity”.

Short to Ground:

3. Set the VOM to measure resistance (“R x 1”

scale). Disconnect Wire 56 from the Starter

Contactor Relay (SCR). Connect one meter test

lead to the SCR terminal from which Wire 56 was

just removed. Connect the other meter test lead to

a clean frame ground. Starter Contactor Relay coil

resistance of 155 ohms should be measured. If

“Continuity” is measured a short to ground exists.

Note: Current draw of the Starter Contactor Relay

coil at nominal voltage is approximately 80ma.

RESULTS:

1. If “Continuity” is not measured in Step 1, repair

or replace Wire 0 between the Starter Contactor

Relay and the ground terminal.

2. If

“

Continuity” was not measured in Step 2 when

the Start-Stop switch was activated to “START”,

replace the Starter Contactor Relay.

3. If “Continuity” is measured in Step 2, go to Test

23.

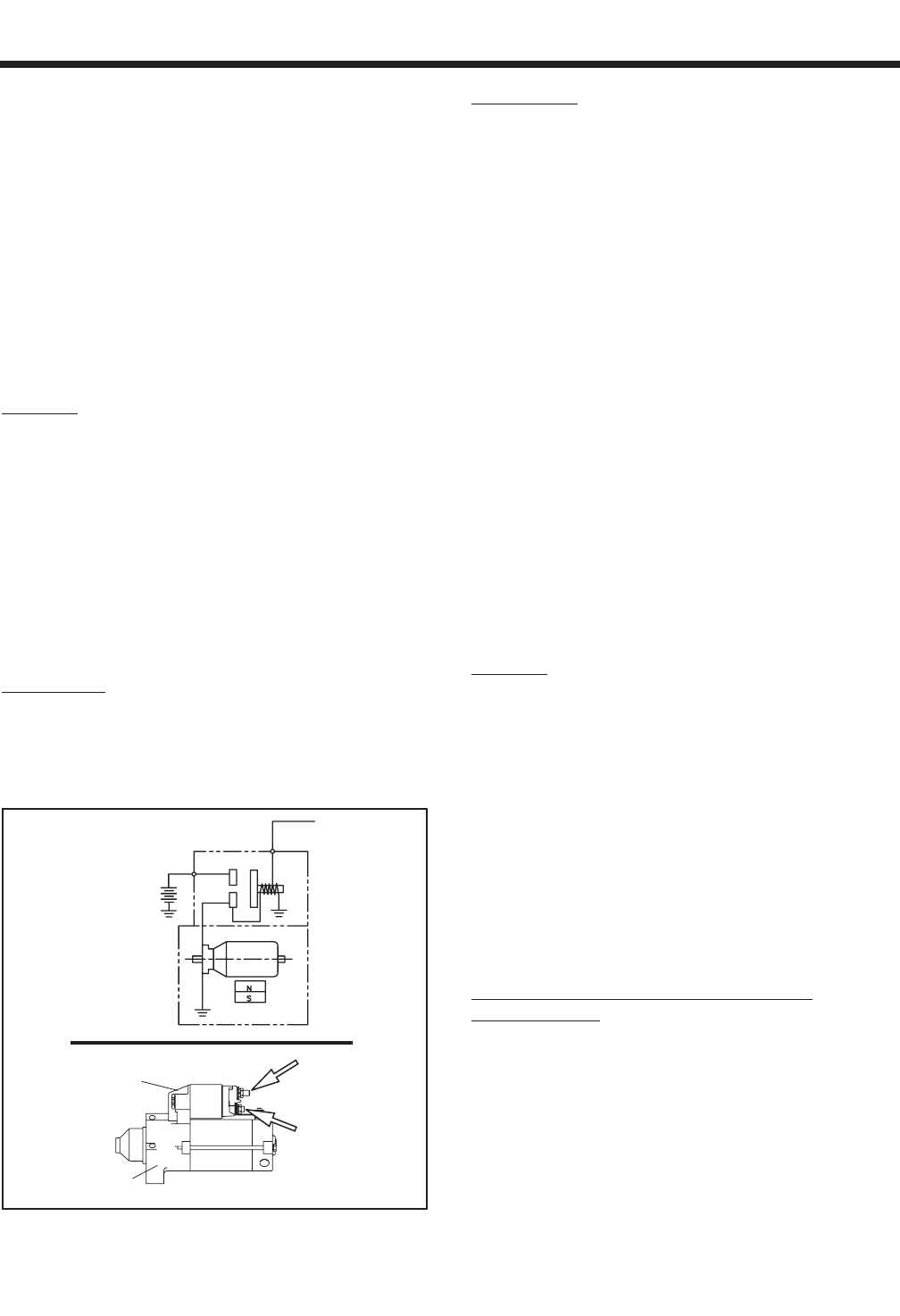

TEST 23 – CHECK STARTER CONTACTOR

DISCUSSION:

The Starter Contactor (SC) must energize and it’s

heavy duty contacts must close or the engine will not

crank. This test will determine if the Starter Contactor

is in working order. The Starter Contactor is connect-

ed to the Starter Motor (see Figure 7-20).

CONNECTING

DIAGRAM

BATTERY

12V

STARTER

SWITCH

PERMANENT MAGNET

30

50

16

STARTER

CONTACTOR

STARTER

MOTOR

STEP 2

TEST POINT

STEP 1

TEST POINT

Figure 7-20. – The Starter Contactor (SC)

PROCEDURE:

1. Carefully inspect the starter motor cable that runs

from the Battery to the Starter Motor. Cable con-

nections should be clean and tight. If connections

are dirty or corroded, remove cable and clean

cable terminals and studs. Replace any cable

that is defective or badly corroded. Set the VOM

to measure DC voltage. Connect the positive

(+) meter test lead to the Starter Contactor stud

that the battery cable is connected to. Connect

the negative (-) meter test lead to a clean frame

ground. Battery voltage should be measured (see

Figure 7-20, STEP 1 TEST POINT).

2. Set the VOM to measure DC voltage. Disconnect

Wire 16 from the Starter Contactor. Connect the

positive (+) meter test lead to Wire 16. Connect

the negative (-) meter test lead to a clean frame

ground. Set the Start-Stop Switch to “START”.

Battery voltage should be indicated. Reconnect

Wire 16 to the Starter Contactor.

3. Set the VOM to measure DC voltage. Connect

the positive (+) meter test lead to the Starter

Contactor stud that has the small jumper wire

connected to the Starter. Connect the negative

(-) meter test lead to a clean frame ground. Set

the Start-Stop Switch to “START”. Battery volt-

age should be measured (see Figure 7-20, STEP 2

TEST POINT).

RESULTS:

1. If battery voltage was not measured in Step 1,

repeat Test 17.

2. If battery voltage was not measured in Step 2,

repair or replace Wire 16 between the Starter

Contactor Relay (SCR) and the Starter Contactor

(SC).

3 If battery voltage was measured in Step 1, but not

in Step 3, replace the Starter Contactor.

4. If battery voltage was measured in Step 3 but the

engine still does not crank, go to Test 24.

TEST 24 – CHECK STARTER MOTOR

CONDITIONS AFFECTING STARTER MOTOR

PERFORMANCE:

1. A binding or seizing condition in the Starter Motor

bearings.

2. A shorted, open or grounded armature.

a. Shorted, armature (wire insulation worn and

wires touching one another). Will be indicated by

low or no RPM.

b. Open armature (wire broken) will be indicated

by low or no RPM and excessive current draw.

c. Grounded armature (wire insulation worn and

wire touching armature lamination or shaft). Will

Page 48

Section 7

DIAGNOSTIC TESTS