SPARTAN LAMINATOR OPERATION & MAINTENANCE MANUAL Part Number: 930-073 Rev: A Rev. Date: 6-9-04 © 2004 GENERAL BINDING CORPORATION. ALL RIGHTS RESERVED. Do not duplicate without written permission.

The information in this publication is provided for reference and is believed to be accurate and complete. GBC is not liable for errors in this publication or for incidental or consequential damage in connection with the furnishing or use of the information in this publication, including, but not limited to, any implied warranty of fitness or merchantability for any particular use. GBC reserves the right to make changes to this publication and to the products described in it without notice.

Spartan Operation and Maintenance Manual Table of contents 1.0 Safety 1.1 Explanation of symbols 1.2 General Rules of safety 1.3 Primary function 1.4 Safety decals Figure 1.4.1 Safety label placement 1-1 1-1 1-2 1-2 1-3 2.0 Warranty 2.1 Limited warranty 2.2 Exclusions to the warranty 2.1 2-1 3.0 Specifications 3.1 Consumable 3.2 Function 3.3 Electrical 3.4 Dimensions and weights Figure 3.4.1 Dimensions 3-1 3-1 3-1 3-1 3-2 4.0 Installation 4.1 Pre-installation 4.2 Suggested floor layout Figure 4.2.

Spartan Operation and Maintenance Manual Page II © 2004 General Binding Corporation

Spartan Operation and Maintenance Manual 1.0 Safety CAUTION: Do not attempt to operate your SPARTAN Laminator until you completely read and understand this Operations and Maintenance Manual. Your safety, as well as the safety of others, is important to General Binding Corporation (GBC). This section contains important safety information which must be adhered to while operating, cleaning and performing basic maintenance in and around the machine. ELECTRICAL HAZARD: [This symbol is used prior to a step.

Spartan Operation and Maintenance Manual 1.3 Primary function 1.4 Safety decals WARNING: Never use this machine for any other purpose than its intended design and function. INFORMATION: Always observe all warning labels placed at various points on the laminator. If you do not completely understand a label, consult your manager for assistance. The Spartan laminator is to be used only as a mounting and laminating machine. Only use acceptable materials when mounting and laminating with this machine.

Spartan Operation and Maintenance Manual Figure 1.4.1 Safety Label Placement WARNING Serious injury may result. Keep hand, clothing and loose articles away from the rollers and heaters. CAUTION Hot surface Avoid contact ! CUIDADO RODILLOS CALIENTES. PUNTO DE PINCHAMIENTO. Mantener manos y ropa a distancia. ! ATTENTION ! CAUTION HOT ROLLS. ROULEAUX CHAUDS. POINT DE PINCEMENT. Tenir mains et vetements a l'ecant. ! WARNUNG HEISSE ROLLEN PINCH POINT. Keep hands and clothing away.

Spartan Operation and Maintenance Manual Page 1-4 © 2004 General Binding Corporation

Spartan Operation and Maintenance Manual 2.0 Warranty GBC Films Group warrants the equipment to be free from defects in material and workmanship for a period of 90 days for parts and labor from the date of installation. This warranty is the only warranty made by GBC Films Group and cannot be modified or amended. DAMAGE OR PERSONAL INJURY ( UNLESS PRIMARILY CAUSED BY ITS NEGLIGENCE ), LOSS OF PROFIT OR OTHER INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OR INABILITY TO USE THE EQUIPMENT. 2.

Spartan Operation and Maintenance Manual This page intentionally left blank.

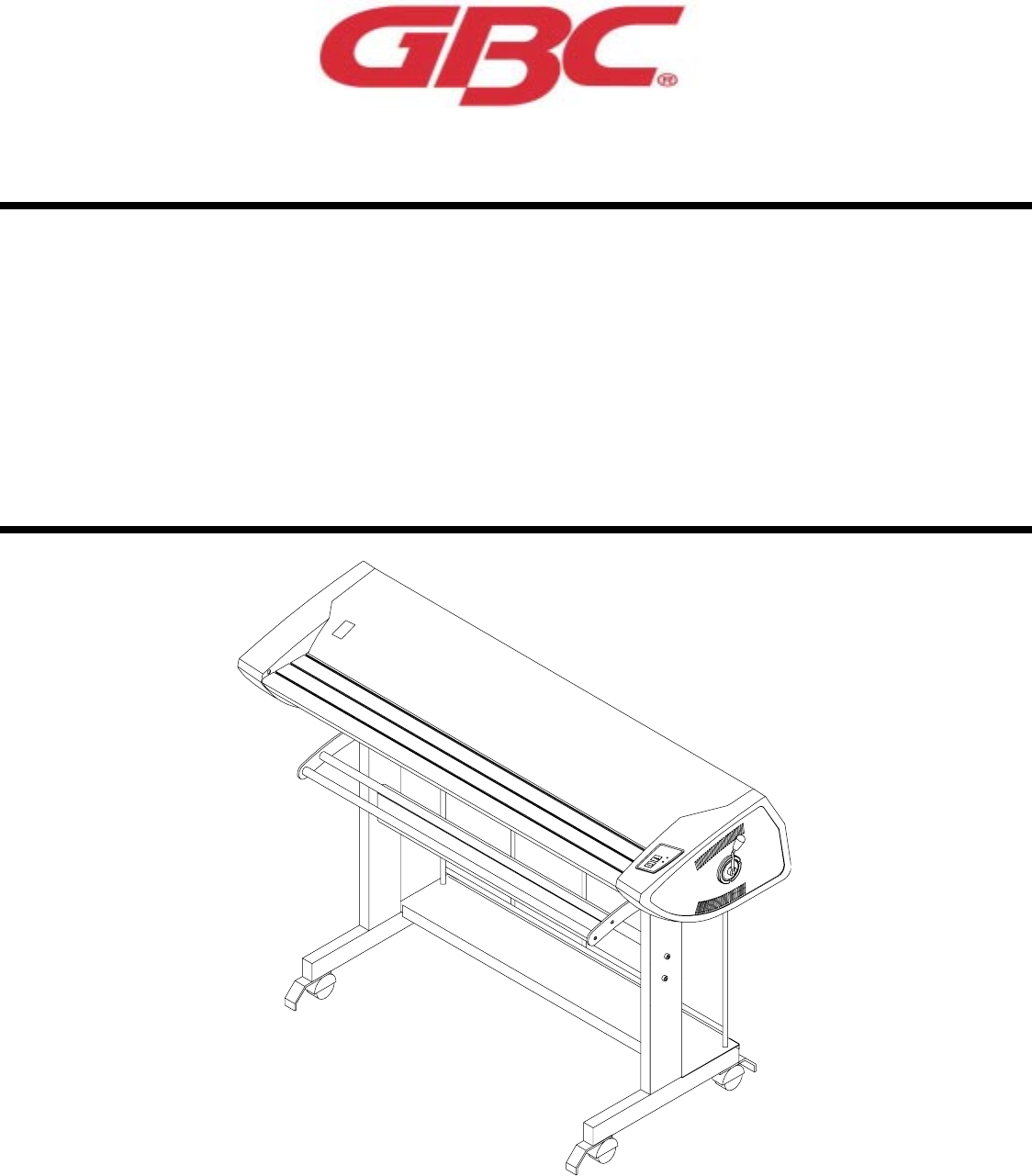

Spartan Operation and Maintenance Manual 3.0 Specifications Description: Entry level laminator for encapsulation and mounting of poster size prints. The Spartan is a self standing laminating unit. Features: Simple one touch operation Applications: Mounting of poster size prints Encapsulation of poster size prints 3.3 Electrical Laminator Rating: 240V, 60 Hz, 2500 W Requirements: 230-240 VAC, 60 Hz, single phase 15 amps. BTU Output: 8,535 BTU/Hour Heater Wattages: 2100 watts Amperage Draw: 3.

Spartan Operation and Maintenance Manual Figure 3.4.1 Dimensions 53 in. (132 cm) RE ADY E OAM H UC PO U S S G U E R PR E GA 42 in. (105 cm) AT IN LAM 18.5 in.

Spartan Operation and Maintenance Manual 4.0 Installation GBC Films Group is committed to a program of ongoing product improvement. As a result, we are providing these instructions so that you can insure that your new Spartan Laminator is properly and securely unpacked, moved and installed. Before a Spartan Laminator can be installed, there are a few requirements that must be met.

Spartan Operation and Maintenance Manual 4.2 Suggested floor layout A safe work area constitutes enough room to work with the materials at hand while being free to move around the laminator without interference from the laminator. Refer to the figure below for a suggested floor layout example. Figure 4.2.1 Suggest floor layout example 4 ft. x 6 ft. 8 ft ( 240 cm ) (101.6 x 152 cm) Work table on wheels Back 18ft. ( 540 ) cm 3 ft ( 90 cm ) Front 4 ft. x 6 ft. 8 ft ( 240 cm ) (101.

Spartan Operation and Maintenance Manual 4.3 Know your laminator Under the cover Before performing any procedure within this manual, it is recommended that you take time to know your laminator.

Spartan Operation and Maintenance Manual 4.4 Unpacking WARNING: Do not attempt to move the laminator across anything other than a flat level surface alone. You can be crushed or seriously injured. INFORMATION: All shipments are ex-works. At our docks, title passes to the buyer. Please review your insurance coverage prior to shipment, as you are responsible for all subsequent freight charges and risks. WARNING: Do not turn the laminator sideways, up side down or vertical when moving.

Spartan Operation and Maintenance Manual 5.0 Operations RUN – When pressed, engages the motor that drives the rollers. WARNING: Do not wear ties, loose fitting clothes or dangling jewelry while operating or servicing the laminator. These items can get caught in the nip and choke you or you can be crushed or burned. CAUTION: Do not block the Top Roll Sensor. If the sensor becomes obstructed, over heating may occur and cause irreparable damage to the rollers or a fire.

Spartan Operation and Maintenance Manual 5.2 Roller pressure handle Laminating position The roller pressure handle sets the roller nip opening for the desired application with the material being used. INFORMATION: Never attempt to alter the factory preset settings for the nip opening or speed. Contact your local service representative if you feel the roller pressure handle requires calibrating. – Use this position when running film pouch type materials. The is the minimum nip opening position.

Spartan Operation and Maintenance Manual 6.0 Applications The Spartan laminator will accommodate GBC mounting boards and lamination pouches. This section will describe how each process is run on the laminator. 5. Press RUN. + 6. Align the leading edge of the pouch board slightly off center of the table. INFORMATION: The leading edge will always be the edge which is sealed. The opposite edge is referred to as the trailing edge.

Spartan Operation and Maintenance Manual 6.2 Mounting boards 7. Gently slide the mounting board into the roller nip until you feel the rollers catch the board. 1. Turn the laminator on. 8. Support the board as it exits the rear of the laminator. 2. Center the image on the board under the protective sheet. Protective sheet Image Board 9. Press STOP and set the pressure handle to the roller release position. 3. Set the pressure handle to the foam pouch position. + 10.

Spartan Operation and Maintenance Manual 6.3 Lamination pouches 6. Wait for READY to illuminate. 7. Press RUN. + INFORMATION: Treat the pouch carriers carefully as they may be reused until you see wrinkles in the lamination. 8. Align the leading edge of the pouch carrier containing 1. Turn the laminator on. the lamination pouch and image slightly off center of the table. 2. Center the lamination pouch between the two sheets of the pouch carrier. Pouch carrier Lamination pouch 9.

Spartan Operation and Maintenance Manual 12. Remove the laminated image from the pouch carrier and trim to desired size. Pouch carrier Laminated image • Laminated pouch output has a tendency to become wavy when excess film to film lamination is left on the outer parameter of the image being laminated. When trimmed to the edge of the sheet, the output should be flat. As the amount of film to film lamination increases, the qualitiy of the output decreases. 6.

Spartan Operation and Maintenance Manual 7.0 Maintenance GBC Films Group laminators require minimal maintenance. However, regular maintenance is essential to keep any piece of precision machinery at peak performance. A maintenance schedule and a section of procedures are included in this section. 7.1 Cabinets, cover and stand ELECTRICAL HAZARD: Remove power from the laminator before cleaning. You can be severely shocked, killed or cause a fire. 1.

Spartan Operation and Maintenance Manual 1. Set the pressure handle to the roller release position 1. Set the pressure handle to the roller release position and raise the cover. and raise the cover. RE ADY P RE GA S U GS U E R E M OA UCH PO ADY R P RE GA S U GS U E RE T INA LAM E M OA UCH PO T INA LAM 2. Use a damp ( use water only to dampen the cloth ) 2. With a rubber cement eraser or Scotch Brite TM gently white terry cloth towel to wipe dust from the upper roller.

General Binding Corporation One GBC Plaza Northbrook, IL 60062-4195