User guide

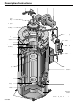

Description/Instructions

Locating the Boiler

a) The boiler should be located in

dry surroundings on a level base,

making sure that there is sufficient

room around the boiler to enable the

operator and/or the maintenance

engineer to gain access to all parts

of the boiler. Check location for

ease of water supply and electrical

connections.

b) Place the boiler on a non-

combustible floor with clearances to

unprotected combustible materials,

including plaster or combustible

supports.

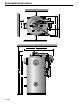

c) It is necessary to have the

following vertical clearance from the

floor to the ceiling for removal of the

burner for servicing:

Minimum Vertical Clearances

BHP Inches Millimeters

4 66 1676

6 76 1930

10 80 2032

15 86 2184

20 90 2286

30 100 2540

40 94 2388

50 102 2591

60 112 2845

d) Make sure the boiler is located

at a safe distance from the fuel oil

tank.

The Fuel Oil Supply

a) Be sure that the oil supply

lines from the tank to the burner

are of proper size. Vacuum should

not exceed 10” of mercury at the

pump inlet.

b) All Fulton oil burners are of the

two pass design system requiring a

return line and supply line. The oil

pump is factory set at 230 psi (=16

Kg/cm

2

). Do not change this setting

without consulting factory.

c) A stop valve, a check valve, and

an oil filter must be installed in the

oil supply line.

d) When one oil line is feeding two

burners, a check valve must be

installed in each unit.

e) Make sure there are no loose fit-

tings. Loose fittings in the fuel oil

line will allow air to enter into the

fuel line and cause improper firing.

8-O 4/00

PLEASE SEE DATA SHEETS ON PREVIOUS PAGES