Service and Parts Manual (2018, 2019, 2020, 2021, 2022)

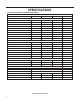

Table Of Contents

- INTRODUCTION

- Important Safety Information

- Personal Injury Or Death Hazards

- Operation of Equipment in During Construction

- Typical Unit Components and Dimensions

- Model Number Reference Guide

- Serial Number Reference Guide

- Product Features

- General Specifications 9-12k Heat Pump Models

- Electrical Data

- Function and Control

- Buttons and Display

- Temperature Definition

- System Basic Function

- 1) Cooling Mode

- 2) Heating Mode

- 3) Room Freeze Protection (AUTO HEATING)

- 4) Temperature Sensor Open Circuit or Short Circuit Protection

- 5) Power cut protection

- 6) Compressor and DC-inverter features

- 7) Smart fresh air system

- Advanced Functions

- Advanced Settings

- Memory Function

- FD Control (front-desk control) & 24V REMOTE THERMOSTAT

- Protection Functions

- System Configuration Fresh Air Vent Control

- Digital Control User Input Configuration

- Settings- Detailed Configurations

- Refrigeration Sequence Of Operation

- Refrigerant System Diagram

- PTAC Installation Recommendations

- Wall Sleeve Installation Instructions (PDXWS)

- Alternate Wall Installations

- PXDR10 Drain Kit Installation

- External Drain

- PXGA Standard Grille

- Chassis Install

- Remote Control Thermostat Installation

- Front Desk Control Terminal

- Final Inspection & Start-up Checklist

- Remove Chassis

- Remove User Interface

- Open Electrical Control Box

- Remove Main PCB (logic) Board

- Remove Power Cord

- Remove Power PCB

- Remove IPM PCB (Inverter Board)

- Remove Blower Wheel (Inside Fan)

- Remove Blower Wheel Motor (Inside Fan)

- Remove Heating Element

- Remove Freshaire Components

- Remove Outdoor Fan

- Remove Reversing valve Solenoid

- Refrigerant Charging

- Undercharged Refrigerant Systems

- Overcharged Refrigerant Systems

- Restricted Refrigerant System

- Sealed System Method of Charging/ Repairs

- Hermetic Components Check

- Reversing Valve Description And Operation

- Testing The Reversing Valve Solenoid Coil

- Checking The Reversing Valve

- Touch Test Chart : To Service Reversing Valves

- Compressor Checks

- Compressor Replacement

- Compressor Replacement -Special Procedure in Case of Compressor Burnout

- Check Indoor Fan Motor

- Check Outdoor Fan Motor

- Check Fan Motor Capacitors

- Main PCB (logic) Board Connector Identification

- Power PCB (Power Board) Connector Identification

- Basic Troubleshooting

- Error code and solutions

- Unit Does Not Operate

- Check Electric Heater Control

- Check Thermistors

- Check Thermistors -Resistance Table of Thermistors (5K)

- Check Thermistors -Resistance Table of Thermistors (50K)(Compressor Discharge Sensor)

- PARTS CATALOG

18 PB

OPERATION

Function and Control

When 32°F < T4 < 44°F, unit will run in electric heating mode to meet the rst cycle demand. From the second

cycle on, heat pump will operate.

When T4≤32°F, the E-heater will operate exclusively.

During heat pump mode, once T3 freezes to 5°F, or any fault occurs, unit will switch over to electric heating

mode.

Outdoor fan control in heat pump mode:

When T4 is above 57°F, outdoor fan runs at low speed to lower the noise;

When T4 drops to 53°F, outdoor fan runs at high speed, in order to ensure the heating capacity.

Electric heating mode:

The unit is equipped with a universal E-heater, which contains two independent heating elements. The 9K BTU unit

incorporates a 2.5kW and a 1.0kW element. The 12K BTU unit incorporates a 3.5kW an s1.5kW element.

Power Cord Selection

Use the appropriate power cord for each heating configuration as shown in the table below.

Power Cord 15A 20A 30A

9K BTU Unit 2.5kW 3.5kW N/A

12k BTU Unit 1.5kW 3.5kW 5kW

Indoor fan control in heating mode:

The indoor fan will run synchronously with the heating demand. During no demand period, it will run

for 30s(heat pump) or 1min(E-heating) after CONSTANT FAN button is turned off, then turns OFF. When

CONSTANT FAN is ON, it will always berunning.

Defrost

In heat pump mode, if the compressor runs continuously for over 30 minutes and T3< 26°F, or runs continuously

for 90 minutes and T3<32°F the unit will enter defrost stage. Indoor fan will shut down. After the defrosting cycle is

finished, the unit turns to E-heating for the first cycle to heat up quickly.

3) Room Freeze Protection (AUTO HEATING)

This is valid only in standby mode. The dual 8 digital tube displays “L0”.

Entry condition: #5 DIP SWITCH is set to ON to enable the indoor freeze protection and the main board detects

the indoor ambient temperature is lower than 50°F(10°C) for 3 consecutive minutes.

Quitting condition: When indoor ambient temperature rises to 55 °F(13°C), the heating will stop.

4) Temperature Sensor Open Circuit or Short Circuit Protection

If the temperature sensor has an open circuit or a short circuit, the ERROR CODE will display on the digital

tube. If the malfunction of the temperature sensor is detected for 30 seconds, the unit will turn off.

5) Power cut protection

After power cut recovery, unit will have a time delay of 2 to 4 minutes to restart E-heating. The DC-inverter soft start

compressor will restart after 3mins.

6) Compressor and DC-inverter features

The DC-inverter compressor has a high efciency rating and energy savings can be 30% to 80%. Operation

voltage range is 160VAC~270VAC, making the unit operation more stable under a wider voltage range power

input. With its soft start feature, power surges can be avoided, and also lower the noise level. Without the

frequent start-stop, room temperature will be more stable and more comfortable.

The high performance IPM contains a PFC module and under heavy loading PF can be up to 99%, thus

decreases EMI pollution to power supply system, and also decreasing power surges.

The compressor driver chip is high performance, making the compressor more stable and reliable