Service and Parts Manual (2018, 2019, 2020, 2021, 2022)

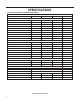

Table Of Contents

- INTRODUCTION

- Important Safety Information

- Personal Injury Or Death Hazards

- Operation of Equipment in During Construction

- Typical Unit Components and Dimensions

- Model Number Reference Guide

- Serial Number Reference Guide

- Product Features

- General Specifications 9-12k Heat Pump Models

- Electrical Data

- Function and Control

- Buttons and Display

- Temperature Definition

- System Basic Function

- 1) Cooling Mode

- 2) Heating Mode

- 3) Room Freeze Protection (AUTO HEATING)

- 4) Temperature Sensor Open Circuit or Short Circuit Protection

- 5) Power cut protection

- 6) Compressor and DC-inverter features

- 7) Smart fresh air system

- Advanced Functions

- Advanced Settings

- Memory Function

- FD Control (front-desk control) & 24V REMOTE THERMOSTAT

- Protection Functions

- System Configuration Fresh Air Vent Control

- Digital Control User Input Configuration

- Settings- Detailed Configurations

- Refrigeration Sequence Of Operation

- Refrigerant System Diagram

- PTAC Installation Recommendations

- Wall Sleeve Installation Instructions (PDXWS)

- Alternate Wall Installations

- PXDR10 Drain Kit Installation

- External Drain

- PXGA Standard Grille

- Chassis Install

- Remote Control Thermostat Installation

- Front Desk Control Terminal

- Final Inspection & Start-up Checklist

- Remove Chassis

- Remove User Interface

- Open Electrical Control Box

- Remove Main PCB (logic) Board

- Remove Power Cord

- Remove Power PCB

- Remove IPM PCB (Inverter Board)

- Remove Blower Wheel (Inside Fan)

- Remove Blower Wheel Motor (Inside Fan)

- Remove Heating Element

- Remove Freshaire Components

- Remove Outdoor Fan

- Remove Reversing valve Solenoid

- Refrigerant Charging

- Undercharged Refrigerant Systems

- Overcharged Refrigerant Systems

- Restricted Refrigerant System

- Sealed System Method of Charging/ Repairs

- Hermetic Components Check

- Reversing Valve Description And Operation

- Testing The Reversing Valve Solenoid Coil

- Checking The Reversing Valve

- Touch Test Chart : To Service Reversing Valves

- Compressor Checks

- Compressor Replacement

- Compressor Replacement -Special Procedure in Case of Compressor Burnout

- Check Indoor Fan Motor

- Check Outdoor Fan Motor

- Check Fan Motor Capacitors

- Main PCB (logic) Board Connector Identification

- Power PCB (Power Board) Connector Identification

- Basic Troubleshooting

- Error code and solutions

- Unit Does Not Operate

- Check Electric Heater Control

- Check Thermistors

- Check Thermistors -Resistance Table of Thermistors (5K)

- Check Thermistors -Resistance Table of Thermistors (50K)(Compressor Discharge Sensor)

- PARTS CATALOG

17 PB

OPERATION

Function and Control

Buttons and Display

1) Buttons

There are ON/OFF, UP, DOWN, HEAT, COOL, CONSTANT FAN and fan speed of HIGH, LOW, AUTO buttons.

1. ON/OFF: Press to turn power on or off to the unit.

2. COOL, HEAT: choose the mode of operation

3. HIGH, LOW, AUTO: choose the fan speed.

4. UP, DOWN: Adjust the setting temperature , default: 60-90°F(16~32°F).

2) Dual 8 Digital Tube Displayer and LED

Two 8 digital tube and 7 LEDs (ON/OFF, HIGH, LOW, AUTO, HEAT, COOL, CONSTANT FAN)

1. Mode LED display: when the unit is running in a certain mode, the corresponding LED is lit up.

2. ON/OFF LED: at ON status, the LED is lit up.

3. CONSTANT FAN LED: when this function is enabled, the LED is lit up.

4. Fan speed LED: when the unit is running at HIGH, LOW or AUTO fan speed, the corresponding LED is litup.

5. Dual 8 digital tube displayer: normally, it displays the indoor ambient temperature. When the UP/DOWN

button is pressed it displays the setting temperature. When some error occurs, it displays the ERROR CODE.

Temperature Denition

Indoor setting temperature (Ts)

Indoor ambient temperature (T1)

Indoor coil temperature (T2)

Outdoor coil temperature (T3)

Outdoor ambient temperature (T4)

Compressor discharge temperature (T5)

Indoor outlet air temperature (T6)

System Basic Function

Once the compressor starts, the compressor won’t stop with the change of the indoor temperature. Once the

compressor stops, it can only start after a 3 mins delay. (The compressor can stop immediately at the time of mode

switchover, turning off the unit, adjusting setting temperature and turning off from a function error.) Depending on the

different ambient temperatures and setting temperatures, the compressor runs at different frequencies to achieve

the best energy savings and comfort. This is the advantage over traditional A/C compressors.

1) Cooling Mode

Working conditions and process for cooling:

When T1≥Ts+2°F(1°C), cooling turns on.

When T1≤Ts-2°F(1°C), cooling turns OFF.

When Ts- 2°F(1°C)<T1<Ts+ 2°F(1°C), the unit keeps previous running status.

Indoor fan control in cooling mode:

The indoor fan will run synchronously with cooling demand. During no demand period if the CONSTANT FAN

button is turned off, it will run for 30s and then turn off..When CONSTANT FAN is ON, it will always be running.

Outdoor fan control in cooling mode:

The outdoor fan has two speeds, low and high. When T4 is above 80°F, the fan operates in high speed.

When T4 drops to 77°F the fan operates in low speed.

2) Heating Mode

Working conditions and process for heating:

When T1≤Ts -2°F(1°C), the unit is running in heating mode. The heat pump or electric heating will start

depending on the ambient temperature condition

When T1≥Ts+ 4°F(2°C), the heating is turned OFF.

When Ts-2°F(1°C) <T1<Ts+ 4°F(2°C), the unit keeps at the previous running status.

Electric heater does not work with heat pump at the same time.

When T4>44°F 7°C, unit will run heat pump all the time.