Manual

1616

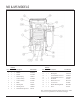

STATIC PROTECTION KIT

GROUNDED HOSE

WITH GROUND WIRE

ASSEMBLY

BONDING

WIRE (NOT

PROVIDED)

NO

SPLASHING

EXPLOSION PROOF OR

AIR MOTOR

GROUND WIRE

WITH PIPE

CLAMP (NOT

INCLUDED)

EXPLOSION PROOF OR

AIR MOTOR

GROUND

WIRE (NOT

INCLUDED)

EARTH GROUND

EARTH GROUND

GROUND WIRE ASSEMBLY

CLAMPED TO EARTH

GROUND

GROUND WIRE ASSEMBLY

CLAMPED TO EARTH

GROUND

DRUM PUMP MIXER

DRUM PUMP INSTALLATION

1. Install the pump and Static Protection Kit as described and

shown.

2. Connect ground wire assembly to earth ground using sup-

plied clamp.

3. Connect ground wire between drum and earth ground.

4. Connect ground wire between receiving container and earth

ground (or use bonding wire to connect to drum).

CAUTION - Check electrical continuity of all components

before pumping. All should be one (1) ohm or less.

TUBE MIXER INSTALLATION

1. Install the mixer and Static Protection Kit as described and

shown.

2. Connect ground wire assembly to earth ground using sup-

plied clamp.

3. Connect ground wire between drum and earth ground.

CAUTION - Check electrical continuity of all components

before pumping. All should be one (1) ohm or less.

OPERATION AND SAFETY GUIDELINES

• Use only metallic pump tubes with explosionproof motors to

transfer ammable or combustible liquids.

• Area for use must comply with NFPA 30 guidelines for safe

storage and use of ammable and combustible liquids.

• All containers and other equipment must be metal and

grounded.

• Follow NFPA 77 guidelines for control of static electricity.

• Avoid splashing. Splash lling can create static electricity

and is extrememly hazardous.

• Fluid velocity must be 3 feet/second maximum (7 GPM in

1" hose).