Instruction Manual

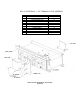

HANDLING AND STACKING HORIZONTAL MODULES

Figure 13

HARDWARE INSTALLATION SEQUENCE

Figure 14

INSTALLING COMPLETED

HARDWARE HORIZONTAL STACK

Figure 15 Figure 16

8.3 Horizontal-Multiple Stacks

8.3.1 Stacking Base Modules

It is recommended that all of the first modules with bottom sup-

ports attached (see Section 8.1.1) be placed in position first. A

chalk line floor mark should be used to assure all stacks will be

in a straight line. This applies for stacks end-to-end or end-to-end

and back-to-back. Refer to Sections 6.5 and 8.1.3 for handling

and tip over procedures.

For stacks end-to-end, module ends should be butted together

so that module side channel ends meet (see Figure 17).

POSITIONING HORIZONTAL BASE MODULES

Figure 17

For stacks back-to-back, the two base modules are positioned to

provide a minimum 4.5” spacing between the bottoms of the

modules (not I-beam edges). Refer back to Figure 1.

Refer to layout/wiring diagram for seismic shim requirements.

8.3.2 Stack Tie Plates

At this time stack tie plates should be installed. It will be neces-

sary to temporarily remove the hardware fastening the base

modules to the I-beams. To achieve maximum stack stability,

especially where seismic conditions may exist, as well as prop-

er interfacing of inter-stack connections, metal tie plates are pro-

vided. The plates used on stacks end to end are 3” x 1” x 1/8”

with two 9/16” holes. Use one tie plate at each interface to con-

nect the module channels of adjacent stacks. See Figure 18.

TIE PLATE ASSEMBLIES - HORIZONTAL STACKS

Figure 18

Position plates on the module channels and secure with hardware

as shown. Where stacks have different heights (for example a 3

high stack adjacent to 4 high stack), install plates on shorter stack

top module and adjacent module. Torque hardware to 47 Newton-

meters (35 Ft-Lbs).

TOP MODULE

BASE MODULE

13