Specifications

50

L510010-04

ENGINE MAINTENANCE - 11

6. After the engine has been properly aligned,

secure the engine mounts.

7. Connect the propeller shaft coupling to the

transmission coupling. Tighten the coupling

attaching bolts and nuts to the correct

specifi cations.

FASTENER TORQUE SPECIFICATIONS

Location Lb-Ft (N

.

m)

Engine Mount to Stringer Securely

Propeller 50 (68)

Trunnion Bolts 45 (61)

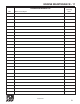

Figure 11-33 Angular Alignment

STRAIGHT

EDGE

TRANSMISSION

OUTPUT FLANGE

.003 INCH

(0.07 mm)

FEELER GAUGE

PROPELLER

SHAFT

COUPLING

FLANGE

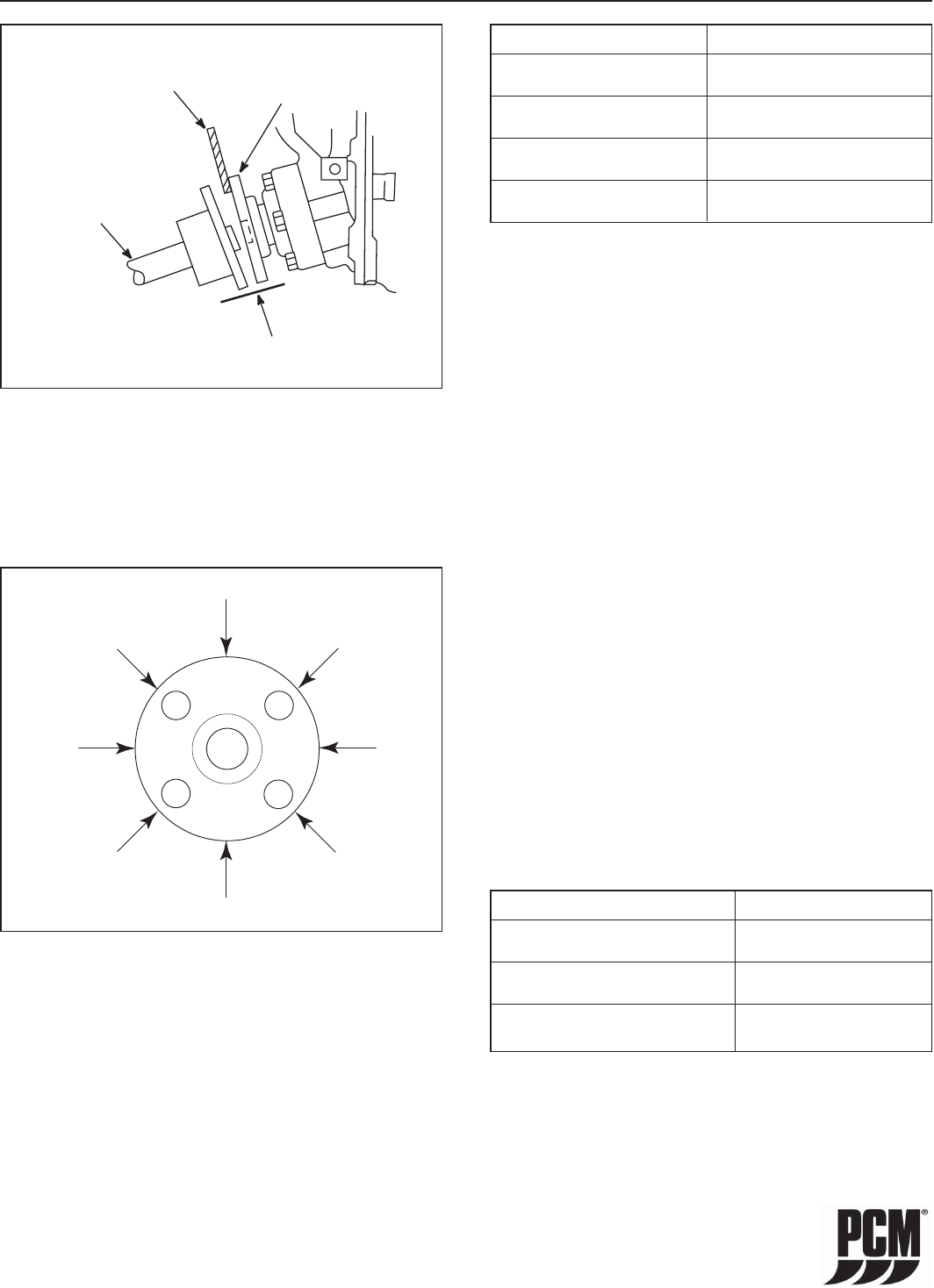

5. Check for any angular misalignment. Hold

coupling faces tightly together by hand and check

for a gap between the coupling faces, with a

0.003 in. (0.07 mm) feeler gauge, at 90-degree

intervals. (Figure 11-34).

Figure 11-34 Angular Alignment Check

A

A

B

B

RC

RC

LC

LC

IMPORTANT: Angular misalignment conditions may

require adjustment of one front mount, both front

mounts, the trunnions, or any combination. Figure 11-34

(Angular Alignment Check) and the following table are to

assist in the alignment process.

Angular Misalignment Front Mount Adjusted

A Both

B Trunnion

LC R

RC L

• To adjust a corner of the engine up or down,

loosen the locking nut. Turn the adjusting nut

or the adjusting bolt in the direction required

to raise or lower the engine. After the

adjustment is complete, tighten the locking

nut.

IMPORTANT: If a “pinch” occurs in the “A” quadrant

(Figure 11-34), correcting the condition will require an

equal adjustment on the front mounts. If a “pinch” occurs

in the “C” quadrant, an adjustment will be made on the

opposing front mount. If a “pinch” occurs in the “B”

quadrant, a trunnion adjustment is required.

• To move the engine left or right, loosen the

trunnion clamping bolt and the nut on all

four mounting brackets. Move the engine

to the left or right, as necessary, to obtain

the proper alignment. After adjustment is

complete, tighten all bolts.