Safety Data Sheets (SDS)

Print Date: 2015-08-06

SDS-Non-Phthalate FlexPVC.docx 3 | P a g e

Flash Point: >600˚F (315˚C)

Extinguishing Media: Water spray, foam, carbon dioxide, or dry chemical

Special Fire Fighting Procedures: As with any fire, combustion byproducts and heat will be generated. Firefighters should be equipped with a self-

contained breathing apparatus and full turnout gear when fighting any fire. Do not attempt to fight any fire unless you have been trained to do so.

Unusual Fire and Explosion Hazards: PVC compounds evolve hydrogen chloride, carbon monoxide and other gases when burned. Exposure to

combustion gases may be fatal.

Section 6 - Accidental Release Measures

Remove unnecessary people from the release area. Wear appropriate personal protective equipment during cleanup. Spills or releases of this

material do not require reporting to the National Response Center. If the material is not contaminated, recover in a manner free of foreign particles or

substances for re-use. If the material is contaminated, scoop, sweep, or vacuum into suitable container for disposal, taking care to avoid the

generation of dust.

Section 7 - Handling & Storage

Stability: Stable Hazardous Polymerization: Will not occur Incompatibility: Avoid contact with strong acids or oxidizing agents.

Storage in a cool, dry location in closed containers away from environmental extremes is recommended. Store away from food, sparks, and open

flame. Minimize dust generation and accumulation. Take measures to avoid static charge accumulation. Heat only in areas of adequate ventilation.

Clean exhaust and ventilating equipment regularly. This product may react with strong oxidizing agents or strong acids and should not be stored near

such materials. As with any material meant for industrial use only, good industrial practices and procedures should be followed at all times when

handling, storing, or processing this material.

Section 8 - SPILL OR LEAK PROCEDURES

Please refer to the applicable American Conference of Governmental Industrial Hygienists.

Ventilation: It is recommended to exhaust processing fumes from the work area. If fume ventilation is used, fume collection ductwork should be

regularly cleaned to remove oily deposits which are very flammable and/or corrosive and irritating to skin or eyes. If dust is generated, dust

collection ventilation may be necessary to maintain airborne concentrations below all applicable exposure limits (see Section II).

Respiratory Protection: When dust is present, A NIOSH/MSHA approved respirator (approved for TC-21C dusts) should be used. If fumes are

present, use a respirator equipped with organic vapor cartridges.

If combustion vapors are present, a full-face self-contained breathing apparatus

should be used. Please reference OSHA standard 29 C.F.R. 1910.134 for all procedures necessary if respirators are issued to any employee(s).

Other Protective Equipment: ANSI approved safety glasses or goggles, protective gloves, work uniforms, and/or disposable coveralls are

recommended. Additionally, each employee working with these materials should have access to an eye wash and complete first aid kit.

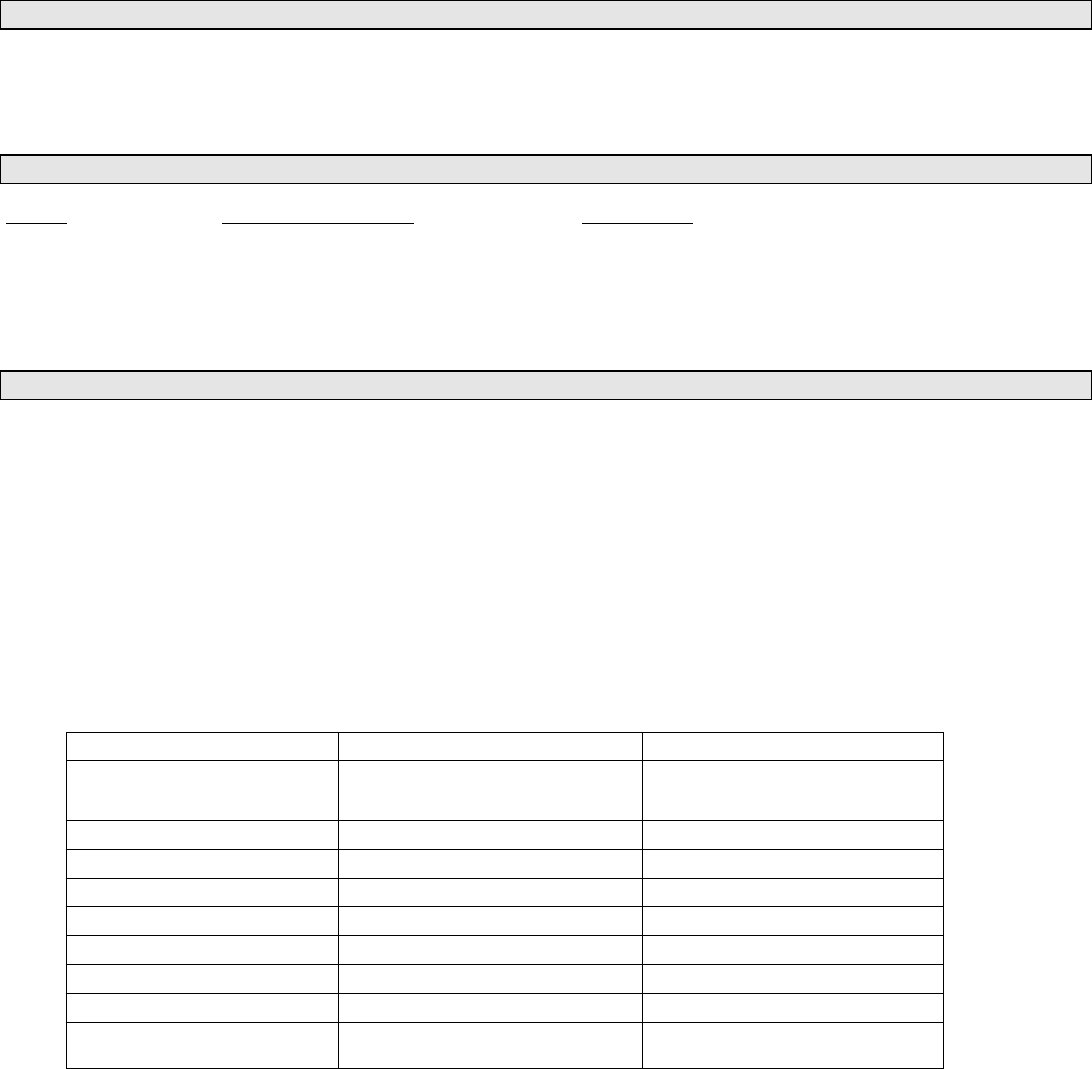

The following substances may be present in this product, but are not anticipated to exceed exposure limits under normal conditions:

Substance OSHA-PEL ACGIH-TLV

Calcium carbonate

15 mg/m3 8-hrs TWA (total dust)

5 mg/m3 8-hrs TWA (respirable)

10 mg/m3 8-hrs TW A

Carbon black 3.5 mg/m3 8-hrs TWA 3.5 mg/m3 h-hrs TW A

Titanium dioxide 10 mg/m3 8-hrs TW A 10 mg/m3 8-hrs TW A (dust)

Antimony trioxide 0.5 mg/m3 8-hrs TWA 0.5 mg/m3 8-hrs TW A

Barium compounds 0.5 mg/m3 8-hrs TWA 0.5 mg/m3 8-hrs TW A

Arsenic compounds*

0.1 mg/m3 8-hrs TWA (inorganic) 0.1 mg/m3 8-hrs TWA (inorganic)

Lead compounds*

0.05 mg/m3 8-hrs TWA 0.05 mg/m3 8-hrs TW A

Vinyl chloride*

1-ppm TWA 1-ppm TWA

Zinc compounds

15 mg/m3 8-hrs TWA (total dust)

5 mg/m3 8-hrs TWA (respirable)

10 mg/m3 8-hrs TW A