Specifications

Table Of Contents

8

KDG4V-3S and KTG4V-3S Application Data

Maximum current @ 50C (122 F)

ambient

G 3.2A

H 1.6A

Power Consumption @ 20C (68F)

G 18 Watts

H 18 Watts

GP 30 Watts

HA 30 Watts

Coil Resistance @ 20C (68 F)

G 1.8 Ohms

H 7.3 Ohms

GP 4.9 Ohms

HA 19.6 Ohms

Coil Inductance @ 1000 Hz

G 7.5 mH

H 29 mH

GP 16 mH

HA 67 mH

The following response times were

measured from the point of

energization/de-energization to the

point of first indication of inlet

pressure change.

Response up to full system pressure is

dependent on the system’s

compressed volume and can vary with

each application.

0–100% (center to full spool travel)

100 msec

100–0% (full spool travel to center –

fast drop out)

15 msec

10–90% (10% full flow to 90% full flow)

100 msec

90–10% (90% full flow to 10% full flow)

25 msec

100–100% (100% full flow travel in

one direction to 100 % full flow travel

in the reverse direction)

80 msec

Step Response Time

Drain

On 2-way valves, “T” is the drain and

must be connected to the tank through

a surge-free line, so there will be no

back pressure at this port.

Solenoid Specifications

Specifications

Maximum operating pressure

(A, B and P ports)

350 bar (5000 psi)

(See “Flow Gain Curves”)

Maximum tank line pressure (T port)

K*G4V-3S:100 bar (1450 psi)

Maximum recommended pressure

drop (four–way models at max. flow)

210 bar (3000psi)*

*At pressure drops above 10 bar (145

psid) dither amplitudes in the electronic

controller may need to be set at or near

minimum to eliminate potential high

frequency circuit noise.

Mounting pattern

ISO–4401–AB–03–4–A, NFPA D03,

CETOP 3

Operating temp 20 to 82C. . .

(–4 to 180F)

Fluid viscosity 16 – 54 cSt. . .

(75–250 SUS)

Weights (approximate)

KDG4V–3S–*–60 2,3 kg (5.06 lbs.). .

KTG4V–3S–*–60 1,75 kg (3.85 lbs.). .

Performance

Frequency Response

18Hz @ –3db

(10Hz @ 45 degree phase lag)

For an amplitude of 25% max stroke

(center to offset) about the 50% position

and DP (P–A–B–T) = 10 bar (145 psid).

See graph on page 14.

Hysteresis

With pulse width modulation: 4%

With direct DC voltage

(GP & HA): 8%

Repeatability: 1%

Deadband : 15–35%

of full solenoid input. Vickers electronic

controllers have a deadband eliminator

to reduce this value to near zero.

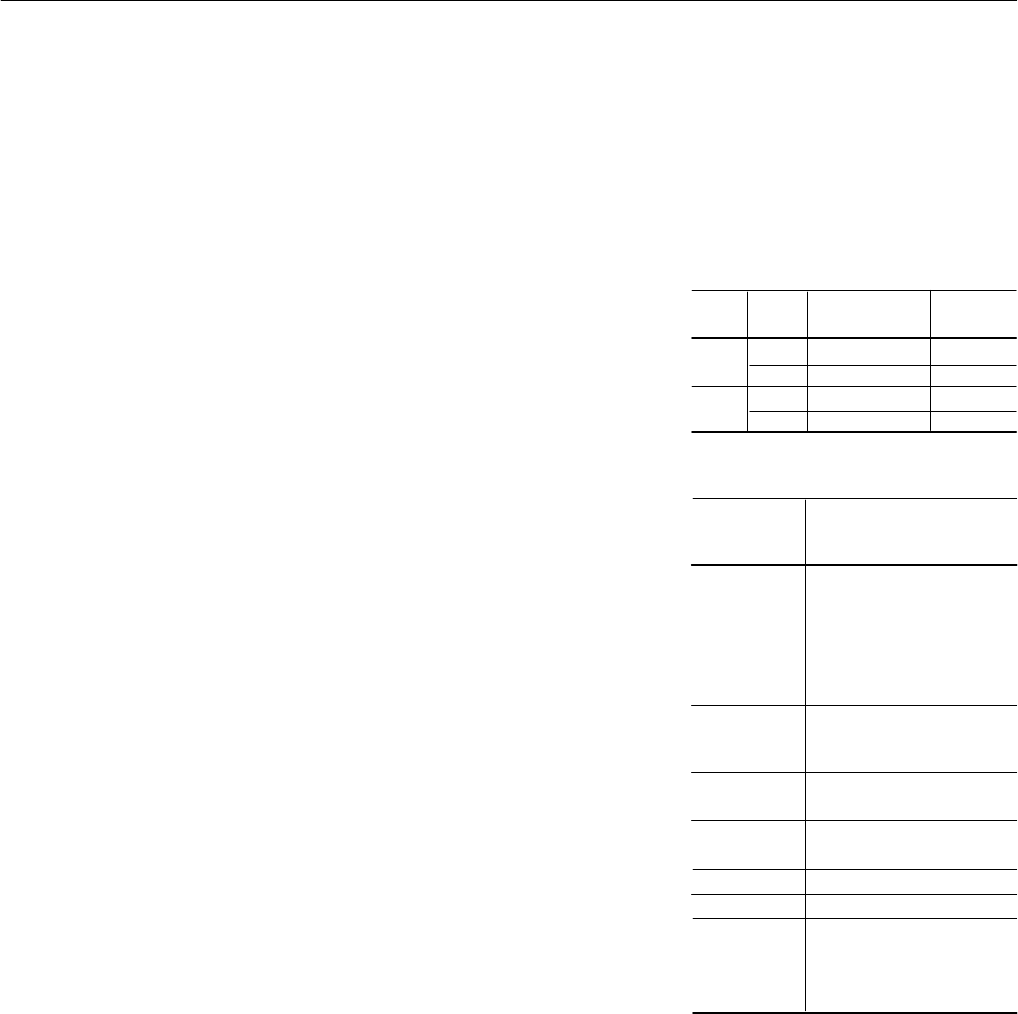

Spool, Spool/Spring,

Metering

Refer to the table below for the

available spools, spool/spring

arrangements and metering conditions.

For example, if a KD valve with a “33”

spool is required, the spool/spring

arrangement is “C” and the metering

condition available is “A”. Refer to

“Model Code” for a definition of

these codes.

Model Spool

Spool/Spring

Arrangement

Metering

Condition

C

C

KD

KT

N

A

EEA–PAM–523–A–32

EEA–PAM–523–B–32

EEA–PAM–523–C–32

EEA–PAM–523–D–32

EEA–PAM–523–E–32

EEA–PAM–523–F–3

2

Amplifiers

Plug Amplifier

EHH–AMP–702–C–20

EHH–AMP–702–D–20

EHH–AMP–702–E–20

EHH–AMP–702–F–20

Amplifier

Coil Voltage

Identification

Letter

GP

HA

H

EEA–PAM–520–A–14

(for use with EN427

models)

G EHH–AMP–712–D/G–20

Refer to drawing I-521575 for information.

EM–VT–12–10

EM–VP–12–10

EM–VT–24–10

EM–VP–24–10

H

H

B or F

B

2

33

2

33

N or S

A