Specifications

Table Of Contents

20

KADG4V-3 and KATG4V-3 Application Data

KAD/TG4V-3 Valves with Integral Amplifiers

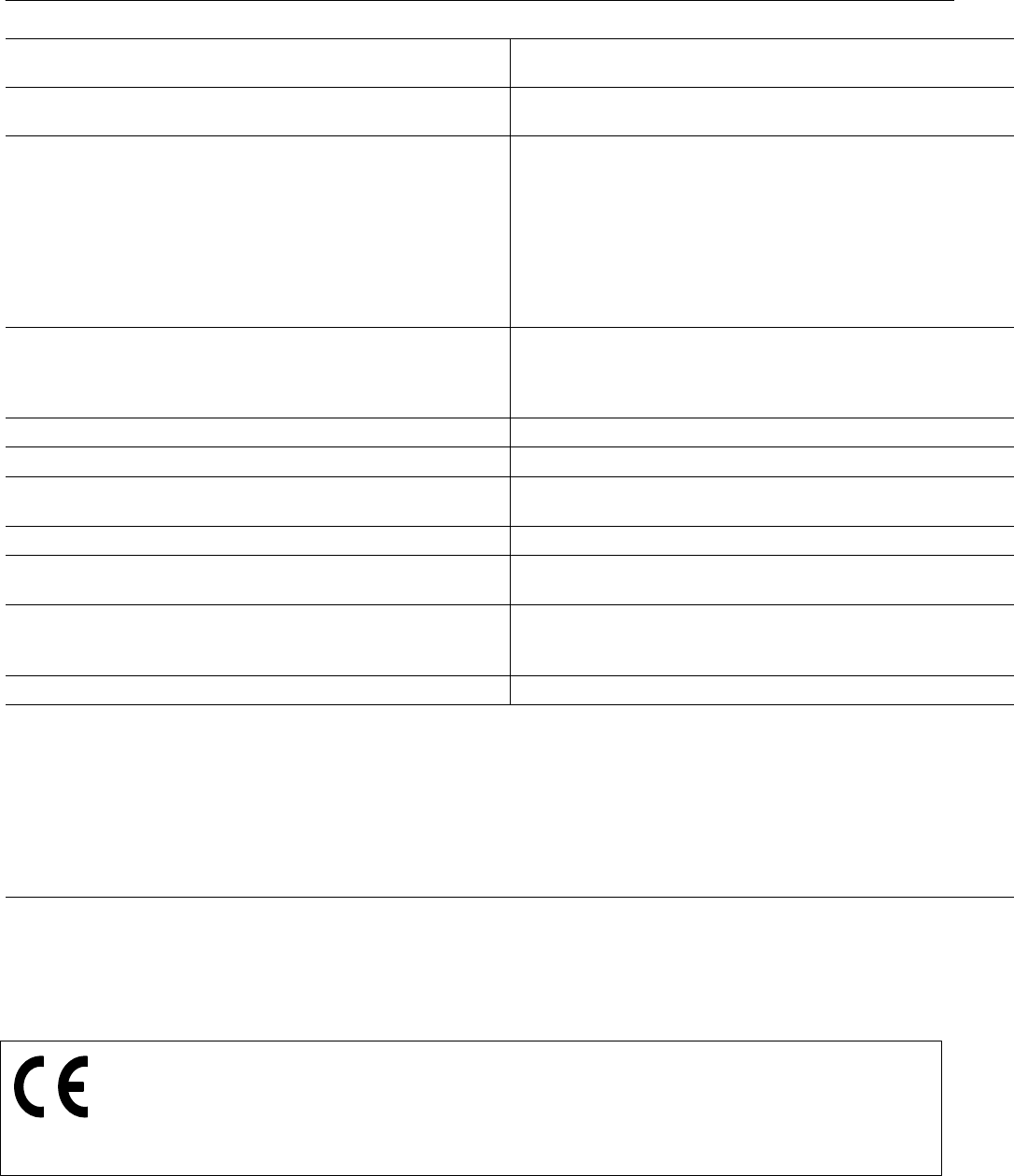

Power supply

24V DC (21V to 36V including 10% peak-to-peak max. ripple)

max. current 3A

Command signal

Input impedance

0 to +10V DC, or 0 to –10V DC, or –10V to +10V DC

47 kΩ

7-pin plug connector

Pin connections:

A

B

C

D

E

F

G

Power supply +ve

Power 0V

Signal 0V

+ve voltage command signal

–ve voltage command signal

Monitor output

Protective ground

Electro-magnetic compatibility (EMC):

Emission (10 v/m)

Immunity (10 v/m)

See notes regarding EMC, below and on pages 18 and 29.

EN 50081-2

EN 50082-2

Gain adjustment 25 to 125%

Factory set adjustments Deadband, gain, dither and offset

Monitor point signal

Output impedance

0,5V per amp solenoid current

10 kΩ

Power stage PWM frequency 2 kHz nominal

Repeatability, valve-to-valve (at factory settings):

Flow gain at 100% command signal

v5%

Protection:

Electrical

Mechanical

Reverse polarity protected

IEC 144, Class IP65

Relative humidity 65 to 85% at 20 to 70C (68 to 158F)

Supporting products:

Auxiliary electronic modules (DIN-rail mounting):

EHA-CON-201-A-2* signal converter

EHD-DSG-201-A-1* command signal generator

EHA-RMP-201-A-2* ramp generator

EHA-PID-201-A-2* PID controller

Subplates, size 03

Mounting bolts

Note: If not using Vickers recommended bolt kits, bolts must be to ISO 898 grade 12.9 or stronger.

This product has been designed and tested to meet specific standards outlined in the European

Electromagnetic Compatibility Directive (EMC) 89/336/EEC, amended by 91/263/EEC, 92/31/EEC and

93/68/EEC, article 5. For instructions on installation requirements to achieve effective protection levels,

see this leaflet, the Installation Wiring Practices for Vickers Electronic Products leaflet 2468, and leaflet

02-123931A which is packed with every KA valve. Wiring practices relevant to this Directive are indicated by

Electromagnetic Compatibility (EMC).