Installation guide

Table Of Contents

- EM135B2511F Robot System Safety and Installation Read this manual first (RC90/RC+5.0) Rev.6

- PREFACE

- TABLE OF CONTENTS

- 1. Safety 1

- 2. Installation 19

- System Example 20

- 2.1 Outline from Unpacking to Operation of Robot System 21

- 2.2 Unpacking 22

- 2.3 Transportation 23

- 2.4 Manipulator Installation 25

- 2.5 Controller Installation 29

- 2.6 Connection to EMERGENCY Connector (Controller) 31

- 2.7 Power Supply 38

- 2.8 Connecting Manipulator and Controller 40

- 2.9 Power-on 41

- 2.10 Saving Default Status 43

- 3. First Step 44

- 4. Second Step 57

- 5. General Maintenance 59

- 6. Manuals 64

- 7. Directives and Norms 66

- 1. Safety

- 1.1 Conventions

- 1.2 Design and Installation Safety

- 1.3 Operation Safety

- 1.4 Maintenance Safety

- 1.5 Emergency Stop

- 1.6 Labels

- 1.7 Safety Features

- Emergency Stop Switch

- Safety Door Input

- Low Power Mode

- Dynamic Brake

- Motor Overload Detection

- Irregular Motor Torque (out-of-control manipulator) Detection

- Motor Speed Error Detection

- Positioning Overflow -Servo Error- Detection

- Speed Overflow -Servo Error- Detection

- CPU Irregularity Detection

- Memory Check-sum Error Detection

- Overheat Detection at the Motor Driver Module

- Relay Deposition Detection

- Over-Voltage Detection

- AC Power Supply Voltage Drop Detection

- Temperature Anomaly Detection

- Fan Malfunction Detection

- 1.8 Lockout / Tagout

- 2. Installation

- System Example

- 2.1 Outline from Unpacking to Operation of Robot System

- 2.2 Unpacking

- 2.3 Transportation

- 2.4 Manipulator Installation

- 2.5 Controller Installation

- 2.6 Connection to EMERGENCY Connector (Controller)

- 2.7 Power Supply

- 2.8 Connecting Manipulator and Controller

- 2.9 Power-on

- 2.10 Saving Default Status

- 3. First Step

- 4. Second Step

- 5. General Maintenance

- 6. Manuals

- 7. Directives and Norms

5. General Maintenance

Safety and Installation (RC90 / EPSON RC+5.0) Rev.6

62

C

ontroller

Inspection Point Inspection Place Daily Monthly Quarterly Biannual Annual

Check whether unusual

sound or vibration is

occurring.

Entire Controller

√ √ √ √ √

Make a backup of data. Project and

system data

Whenever data is changed.

Tightening Hexagon Socket Head Cap Bolts

Hexagon socket head cap bolts are used in places where mechanical strength is

required. (A hexagon socket head cap bolt will be called a “bolt” in this manual.)

These bolts are fastened with the tightening torques shown in the following table.

When it is necessary to refasten these bolts in some procedures in this manual

(except special cases as noted), use a torque wrench so that the bolts are fastened

with the appropriate tightening torques as shown below.

Bolt Tightening Torque

M3

245 N⋅cm (25 kgf⋅cm)

M4

490 N⋅cm (50 kgf⋅cm)

M5

980 N⋅cm (100 kgf⋅cm)

M6

1,760 N⋅cm (180 kgf⋅cm)

M8

3,720 N⋅cm (380 kgf⋅cm)

M10

7,350 N⋅cm (750 kgf⋅cm)

M12

12,740 N⋅cm (1,300 kgf⋅cm)

Refer below for the set screw.

Set Screw Tightening Torque

M4

245 N⋅cm (25 kgf⋅cm)

M5

392 N⋅cm (40 kgf⋅cm)

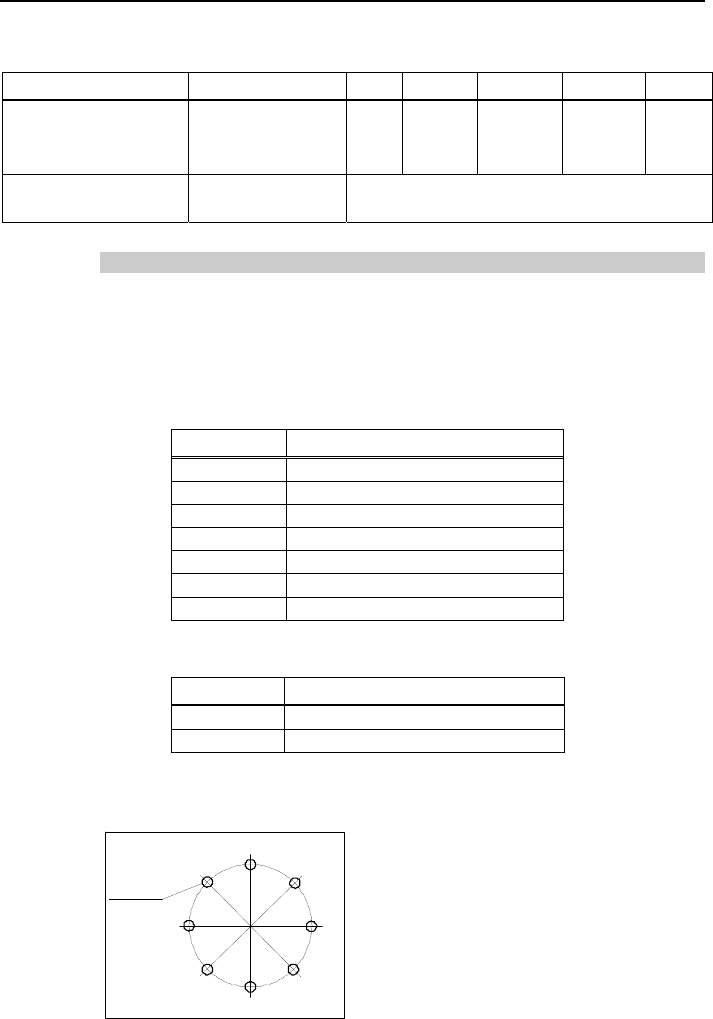

The bolts aligned on a circumference should be fastened in a crisscross

p

attern as

shown in the figure below.

1

5

3

7

2

6

4

8

Bolt hole

Do not fasten all bolts securely at one time.

Divide the number of times that the bolts are

fastened into two or three and fasten the bolts

securely with a hexagonal wrench. Then, use

a torque wrench so that the bolts are fastene

d

with tightening torques shown in the table

above.