Installation guide

Table Of Contents

- EM135B2511F Robot System Safety and Installation Read this manual first (RC90/RC+5.0) Rev.6

- PREFACE

- TABLE OF CONTENTS

- 1. Safety 1

- 2. Installation 19

- System Example 20

- 2.1 Outline from Unpacking to Operation of Robot System 21

- 2.2 Unpacking 22

- 2.3 Transportation 23

- 2.4 Manipulator Installation 25

- 2.5 Controller Installation 29

- 2.6 Connection to EMERGENCY Connector (Controller) 31

- 2.7 Power Supply 38

- 2.8 Connecting Manipulator and Controller 40

- 2.9 Power-on 41

- 2.10 Saving Default Status 43

- 3. First Step 44

- 4. Second Step 57

- 5. General Maintenance 59

- 6. Manuals 64

- 7. Directives and Norms 66

- 1. Safety

- 1.1 Conventions

- 1.2 Design and Installation Safety

- 1.3 Operation Safety

- 1.4 Maintenance Safety

- 1.5 Emergency Stop

- 1.6 Labels

- 1.7 Safety Features

- Emergency Stop Switch

- Safety Door Input

- Low Power Mode

- Dynamic Brake

- Motor Overload Detection

- Irregular Motor Torque (out-of-control manipulator) Detection

- Motor Speed Error Detection

- Positioning Overflow -Servo Error- Detection

- Speed Overflow -Servo Error- Detection

- CPU Irregularity Detection

- Memory Check-sum Error Detection

- Overheat Detection at the Motor Driver Module

- Relay Deposition Detection

- Over-Voltage Detection

- AC Power Supply Voltage Drop Detection

- Temperature Anomaly Detection

- Fan Malfunction Detection

- 1.8 Lockout / Tagout

- 2. Installation

- System Example

- 2.1 Outline from Unpacking to Operation of Robot System

- 2.2 Unpacking

- 2.3 Transportation

- 2.4 Manipulator Installation

- 2.5 Controller Installation

- 2.6 Connection to EMERGENCY Connector (Controller)

- 2.7 Power Supply

- 2.8 Connecting Manipulator and Controller

- 2.9 Power-on

- 2.10 Saving Default Status

- 3. First Step

- 4. Second Step

- 5. General Maintenance

- 6. Manuals

- 7. Directives and Norms

5. General Maintenance

Safety and Installation (RC90 / EPSON RC+5.0) Rev.6

60

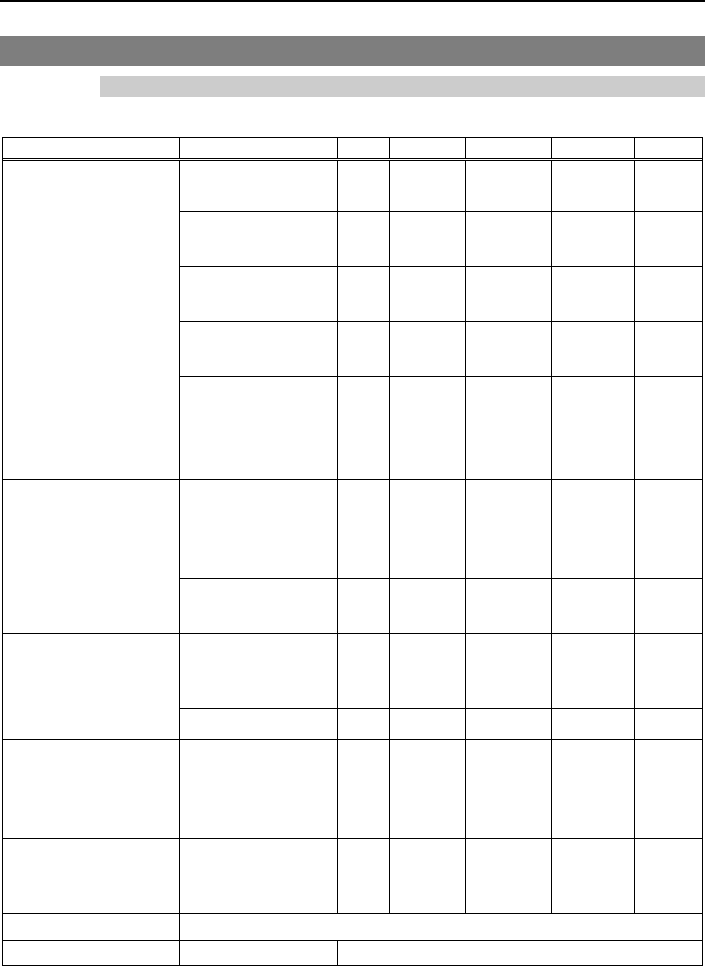

5.2 Inspection Point

Inspection While the Power is OFF (Manipulator is not operating)

M

anipulator

Inspection Point Inspection Place Daily Monthly Quarterly Biannual Annual

End effector

mounting bolts

√ √ √ √ √

Manipulator

mounting bolts

√ √ √ √ √

Each arm locking

bolts

√ √ √ √ √

Bolts/screws

around shaft

√

Check looseness or

backlash of

bolts/screws.

Tighten them if

necessary.

(For the tightening

torque, refer to

Tightening Hexagon

Socket Head Cap

Bolts.)

Bolts/screws

securing motors,

reduction gear

units, etc.

√

External connectors

on Manipulator (on

the connector plates

etc.)

√ √ √ √ √

Check looseness of

connectors.

If the connectors are

loosen, push it

securely or tighten.

Manipulator cable

unit

√ √ √ √

External

appearance of

Manipulator

√ √ √ √ √

Visually check for

external defects.

Clean up if necessary.

External cables

√ √ √ √

Check for bends or

improper location.

Repair or place it

properly if necessary.

Safeguard etc. √ √ √ √ √

Check tension of

timing belts.

Tighten it if necessary.

Inside of Arm #2 √ √

Grease conditions Refer to Greasing.

Battery - Every 1.5 years