Installation guide

Table Of Contents

- EM135B2511F Robot System Safety and Installation Read this manual first (RC90/RC+5.0) Rev.6

- PREFACE

- TABLE OF CONTENTS

- 1. Safety 1

- 2. Installation 19

- System Example 20

- 2.1 Outline from Unpacking to Operation of Robot System 21

- 2.2 Unpacking 22

- 2.3 Transportation 23

- 2.4 Manipulator Installation 25

- 2.5 Controller Installation 29

- 2.6 Connection to EMERGENCY Connector (Controller) 31

- 2.7 Power Supply 38

- 2.8 Connecting Manipulator and Controller 40

- 2.9 Power-on 41

- 2.10 Saving Default Status 43

- 3. First Step 44

- 4. Second Step 57

- 5. General Maintenance 59

- 6. Manuals 64

- 7. Directives and Norms 66

- 1. Safety

- 1.1 Conventions

- 1.2 Design and Installation Safety

- 1.3 Operation Safety

- 1.4 Maintenance Safety

- 1.5 Emergency Stop

- 1.6 Labels

- 1.7 Safety Features

- Emergency Stop Switch

- Safety Door Input

- Low Power Mode

- Dynamic Brake

- Motor Overload Detection

- Irregular Motor Torque (out-of-control manipulator) Detection

- Motor Speed Error Detection

- Positioning Overflow -Servo Error- Detection

- Speed Overflow -Servo Error- Detection

- CPU Irregularity Detection

- Memory Check-sum Error Detection

- Overheat Detection at the Motor Driver Module

- Relay Deposition Detection

- Over-Voltage Detection

- AC Power Supply Voltage Drop Detection

- Temperature Anomaly Detection

- Fan Malfunction Detection

- 1.8 Lockout / Tagout

- 2. Installation

- System Example

- 2.1 Outline from Unpacking to Operation of Robot System

- 2.2 Unpacking

- 2.3 Transportation

- 2.4 Manipulator Installation

- 2.5 Controller Installation

- 2.6 Connection to EMERGENCY Connector (Controller)

- 2.7 Power Supply

- 2.8 Connecting Manipulator and Controller

- 2.9 Power-on

- 2.10 Saving Default Status

- 3. First Step

- 4. Second Step

- 5. General Maintenance

- 6. Manuals

- 7. Directives and Norms

2. Installation

Safety and Installation (RC90 / EPSON RC+5.0) Rev.6

27

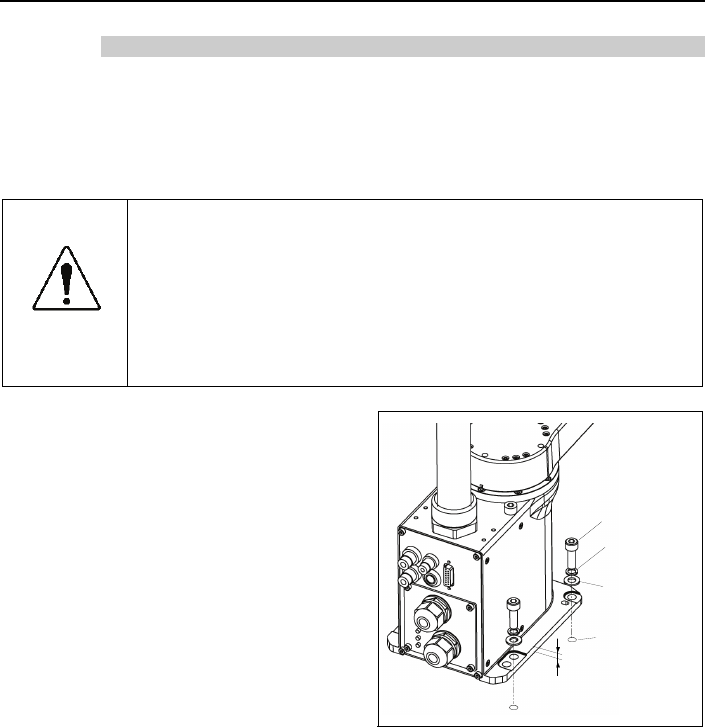

Installation Procedure

When the Manipulator is Clean-model, unpack it outside of the clean room.

)

NOTE

Secure the Manipulator not to fall, and then wipe off the dust on the

Manipulator with a little alcohol or distilled water on a lint-free cloth. After

that, carry the Manipulator in the clean room. Connect an exhaust tube to

the exhaust port after installation.

CAUTION

■

Install the LS series Manipulator with two or more people.

The Manipulator weights are as follows. Be careful not to get

hands, fingers, or feet caught and/or have equipment damaged by

a fall of the Manipulator.

LS3-401* : approx. 14 kg: 31 lb.

LS6-602* : approx. 17 kg: 37.5 lb.

10 mm

4-M8

×

25

Screw Hole

(depth 20 m m

or more)

Spring

Washer

Plan e

Washer

(1) Secure the base to the base

table with four bolts.

Use bolts with specifications

conforming to ISO898-1

Property Class: 10.9 or 12.9.

)

NOTE