Operating instructions

Installation

4. Using the template make the block-

off plate of 24 gauge or thicker steel.

Drill two (2) holes in each ange for

mounting the plate.

5. Mount the block-off plate using

masonry screws in a masonry

replace and sheet metal screws on a

zero-clearance replace (screws need

only be long enough to penetrate the

rst layer of metal).

6. Insulate the block-off plate using high

- temperature berglass insulation

and furnace cement.

7. After installing the unit into place and

the pipe through the block-off plate,

use high - temperature berglass

insulation and furnace cement to seal

any gaps between the pipe and block-

off plate (allow the cement to dry for

at least 24 hours before burning).

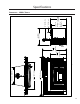

Figure 19: Insert Install into a Zero-Clearance Fireplace.

Fig. 20: Masonry Fireplace Direct Connection Insert

20

Mantel

Surround Panel

USA 16” (406 mm)

CND 18” (450 mm)

Block-off plate or

damper adaptor.

Stainless steel chimney

connector must extend

12" (305mm) past the

block-off plate.

Damper must

be removed

Zero-clearance

(metal) firebox

Masonry Fireplace

Mantel

Damper removed

or fastened open

Surround Panel

USA 16” (406 mm)

CND 18” (450 mm)

Block-off plate or

damper adaptor.

The stainless steel

chimney connector

must extend 12"

(305mm) past the

block-off plate.

Zero Clearance Notes:

The replace must not be altered, except for the exceptions below. The

permanent metal warning label provided must be attached to the back of the

replace, stating that the replace may have been altered to accommodate

the insert, and must be returned to original condition for use as a conventional

replace. The following modication of factory built

replaces are permissible: removal of damper, removal

of smoke shelf or bafe, removal of ember catches,

removal of re grate, removal of viewing screen/curtain,

and removal of doors. The factory built chimney must be

listed per UL 127 (US), and meet type HT requirements

of UL 103 (US). Factory built replace chimneys tested

to UL 127-1998, may be at the replace manufacturer’s

option, tested to the same criteria as UL 103 HT

requirements. If the chimney is not listed as meeting HT

requirements, or if the factory built replace was tested

prior to 1998, a full height listed chimney liner must be

installed from the appliance ue collar to the chimney top.

The liner must meet type HT requirements (2100°F) per

UL 1777 (US). The liner must be securely attached to the

insert ue collar and the chimney top. To prevent room

air passage to the chimney cavity of the replace, seal

either the damper area around the chimney liner with high

temperature sealant or the replace front with berglass

batting.