User manual

87

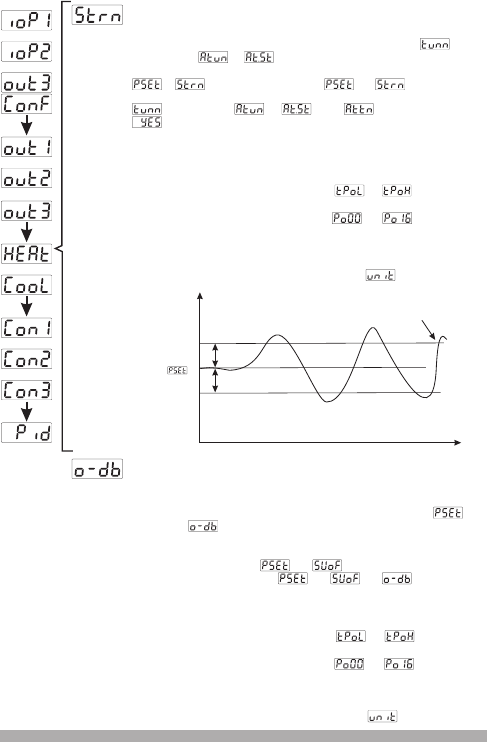

PROCESS VALUE STABILIZATION

( 1, SCALE HIGH POINT)

PROPORTIONAL BAND SHIFTING

((- SCALE HIGH POINT / 2 ) , ( SCALE LOW POINT / 2 ) )

If heating-cooling or only cooling function is performed ;

Cooling process set value is calculated by adding set value with

parameter

Control form can be ON/OFF or PID.

If set value for heating = + ;

Then set value for cooling = + +

It is used to control if process value oscillates or not when

Parameter is or

If;

- <= Process Value <= + condition is not

true and process value starts to oscillate (as shown in the diagram). If

parameter is or ,then parameter is selected

and thenLimit Cycle Tune operation starts for determinig new

PID parameters.

Process

Value

Time

Auto Tune

Starting

Strn

Strn

Process Set

Value ( )

Note: Point position changes according to process input type and

scale,

Unit changes according to the selection in this parameter.

Note: Point position changes according to process input type and

scale ,

Unit changes according to the selection in this parameter.

Scale High Point : Maximum process input value in Pt-100 and Tc

inputs

9999 for fixed dual point calibration used inputs,

Scale high point is the biggest one from or for selectable

dual point calibration used inputs

Scale high point is the biggest one from or for multi point

calibration used inputs

Scale High Point : Maximum process input value in Pt-100 and Tc

inputs

9999 for fixed dual point calibration used inputs,

Scale high point is the biggest one from or for selectable

dual point calibration used inputs

Scale high point is the biggest one from or for multi point

calibration used inputs

OR

OR

OR

OR

OR

OR

IS

SELECTED

OR

IF