Instructions

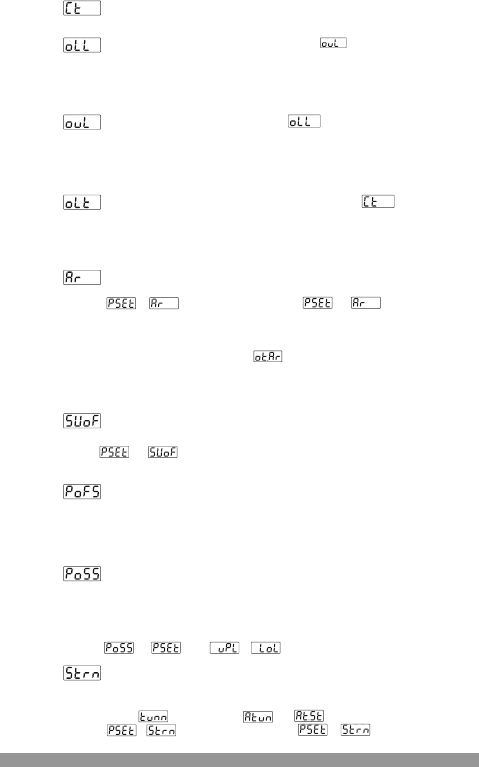

CONTROL PERIOD TIME (1, 150)

Process output period time.

Second

MINIMUM CONTROL OUTPUT ( 0.0% , )

It is % of minimum output.

Even as a result of the PID calculation device calculates the

% output value less than this parameter, heating or cooling

output is active minimum for OLL parameter.

MAXIMUM CONTROL OUTPUT ( , 100.0%)

It is % of maximum output.

Even as a result of the PID calculation device calculates the

% output value greater than this parameter, heating or

cooling output is active maximum for OUL parameter.

MINIMUM CONTROL OUTPUT TIME ( 0.0 sec , )

Heating or cooling output can not be active less than this

parameter. Even if this parameter is 0, this parameter is

accepted 50 msecs for security.

SET VALUE OFFSET

((-SCALEHIGH POINT / 2) , (SCALE HIGH POINT / 2) )Unit

+ is used as set value in PID calculations. It is

used for shifting the proportional band.

(FOR HEATING PID 0.0, 100.0)%

(FOR COOLING PID -100.0, 0.0)%

This parameter is added to “Output %” which is calculated at

the end of the PID.

PID OUTPUT OFFSET

This parameter is added to the % process output that is

calculated at the end of the PID according to process set value.

* / ( - )

OUTPUT OFFSET RELATED TO PID SET

(FOR HEATING PID 0.0, 100.0)%

(FOR COOLING PID -100.0, 0.0)%

PROCESS VALUE STABILIZATION

(1, SCALE HIGH POINT)Unit

It is used for controlling if process value oscillates or not

when parameter is or if;

- <= Process Value <= + condition

is not true, then device start tune operation automatically.

ANTI-RESET WINDUP

While PID operation is running if

- <= process value <= +

condition is true, integral value is calculated. If the

condition is not true, integral value is not calculated and

last calculated integral value is used.

If Ar Parameter is selected , heating proportional

band is used for heating PID process instead of Ar

Parameter and cooling proportional band is used for

cooling PID process instead of Ar Parameter.

(0, SCALE HIGH POINT)Unit

10