Instructions

Installat�on

In package,

-One p�ece un�t

-Two p�eces mount�ng clamp

-One p�ece �nstruct�on manual

A v�sual �nspect�on of th�s product for poss�ble damage occured

dur�ng sh�pment �s recommended before �nstallat�on. It �s your

respons�b�l�ty to ensure that qual�f�ed mechan�cal and electr�cal

techn�c�ans �nstall th�s product.

If there �s danger of ser�ous acc�dent result�ng from a fa�lure or defect

�n th�s un�t, power off the system and the electr�cal connect�on of the

dev�ce from the system.

The un�t �s normally suppl�ed w�thout a power sw�tch or a fuse. Use

power sw�tch and fuse as requ�red.

Be sure to use the rated power supply voltage to protect the un�t

aga�nst damage and to prevent fa�lure.

Keep the power off unt�l all of the w�r�ng �s completed so that electr�c

shock and trouble w�th the un�t can be prevented.

Never attempt to d�sassemble, mod�fy or repa�r th�s un�t. Tamper�ng

w�th the un�t may results �n malfunct�on, electr�c shock or f�re.

Do not use the un�t �n combust�ble or explos�ve gaseous

atmospheres. Dur�ng the equ�pment �s putted �n hole on the metal

panel wh�le mechan�cal �nstallat�on some metal burrs can cause

�njury on hands, you must be careful.

Montage of the product on a system must be done w�th �t’s mount�ng

clamp. Do not do the montage of the dev�ce w�th �nappropr�ate

mount�ng clamp. Be sure that dev�ce w�ll not fall wh�le do�ng the

montage.

It �s your respons�b�l�ty �f th�s equ�pment �s used �n a manner not

spec�f�ed �n th�s �nstruct�on manual.

Before beg�nn�ng �nstallat�on of th�s product, please

read the �nstruct�on manual and warn�ngs below

carefully.

Warranty

EMKO Elektron�k warrants that the equ�pment del�vered �s free from

defects �n mater�al and workmansh�p. Th�s warranty �s prov�ded for a

per�od of two years. The warranty per�od starts from the del�very

date.

Th�s warranty �s �n force �f duty and respons�b�l�t�es wh�ch are

determ�ned �n warranty document and �nstruct�on manual performs

by the customer completely.

Ma�ntenance

Repa�rs should only be performed by tra�ned and spec�al�zed

personnel. Cut power to the dev�ce before access�ng �nternal parts.

Do not clean the case w�th hydrocarbon-based solvents (Petrol,

Tr�chlorethylene etc.). Use of these solvents can reduce the

mechan�cal rel�ab�l�ty of the dev�ce. Use a cloth dampened �n ethyl

alcohol or water to clean the external plast�c case.

Other Informat�ons

Manufacturer Informat�on:

Emko Elektron�k Sanay� ve T�caret A.Ş.

Dem�rtaş Organ�ze Sanay� Bölges� Karanf�l Sk. No:6 16369

BURSA/TURKEY

Phone: +90 224 261 1900

Fax: +90 224 261 1912

a

Repa�r and Ma�ntenance Serv�ce Informat�on:

Emko Elektron�k Sanay� ve T�caret A.Ş.

Dem�rtaş Organ�ze Sanay� Bölges� Karanf�l Sk. No:6 16369

BURSA/TURKEY

Phone: +90 224 261 1900

Fax : +90 224 261 1912

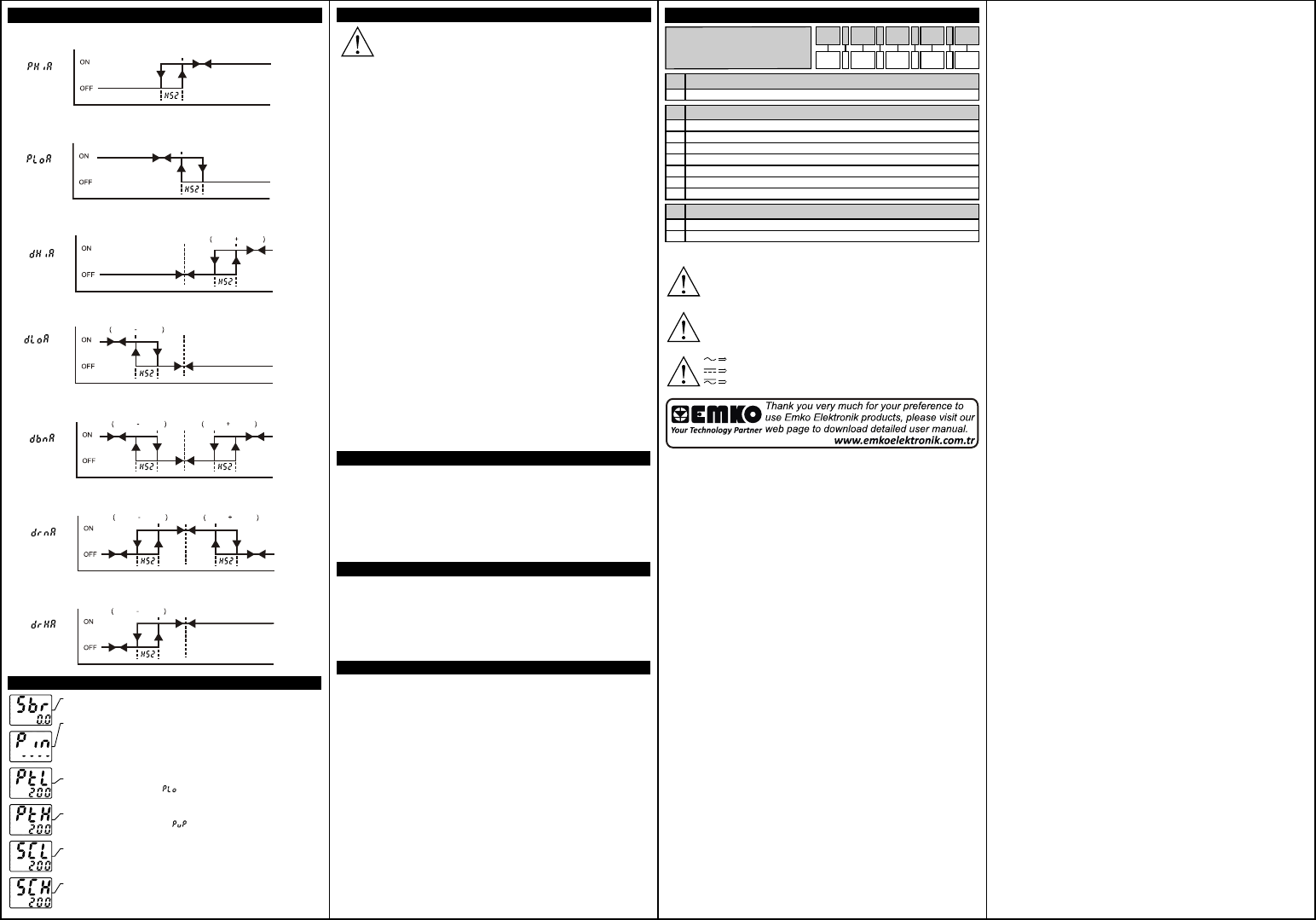

Alarm Types

Set 2

Alarm

Output

Process Value

Process H�gh

Alarm

Process Low

Alarm

Set 2

Alarm

Output

Process Value

Dev�at�on Low

Alarm

Alarm

Output

Process Value

Set 1Set 1 Set 2

Dev�at�on H�gh

Alarm

Set 1 Set 1 Set 2

Alarm

Output

Process Value

Dev�at�on Band

Alarm

Set 1 Set 2 Set 1 Set 1 Set 2

Alarm

Output

Process Value

Dev�at�on Range

Alarm

Set 1 Set 2 Set 1 Set 1 Set 2

Alarm

Output

Process Value

Set 1 Set 2 Set 1

Dev�at�on Range

H�gh Alarm

Alarm

Output

Process Value

1-Sensor fa�lure �n analog �nputs. Sensor connect�on �s wrong or there

�s no sensor connect�on.

a

2-If programm�ng sect�on enter�ng password �s d�fferent from “0” and

user accesses to the parameter by enter button w�thout enter�ng the

password and wants to change a parameter, the warn�ng message �s

shown on the bottom d�splay as shown on the left. Dev�ce does not

allow to do any changes w�thout enter�ng the password correctly.

a

3-If value that �s read from the analog �nput �s lower than process set

low l�m�t parameter value ( ), value on the top d�splay starts to bl�nk

as shown on the p�cture.

a

4-If value that �s read from the analog �nput �s h�gher than process set

h�gh l�m�t parameter value ( ), value on the top d�splay starts to

bl�nk as shown on the p�cture.

a

5-If value that �s read from the analog �nput �s lower than sensor scale

low l�m�t, value on the top d�splay starts to bl�nk as shown on the

p�cture.

a

6-If value that �s read from the analog �nput �s h�gher than sensor scale

h�gh l�m�t, value on the top d�splay starts to bl�nk as shown on the

p�cture.

PO2

PO1

AL1

AL2

°C

°F

/

Error Messages

PO2

PO1

AL1

AL2

°C

°F

/

PO2

PO1

AL1

AL2

°C

°F

/

PO2

PO1

AL1

AL2

°C

°F

/

PO2

PO1

AL1

AL2

°C

°F

/

PO2

PO1

AL1

AL2

°C

°F

/

Before comm�ss�on�ng the dev�ce, parameters must be set �n

accordance w�th des�red use. Incomplete or �ncorrect conf�gurat�on

can cause dangerous st�uat�ons.

Because of l�m�ted mechan�cal l�fe of relay output contact, SSR

output �s recommended wh�ch the dev�ce use PID control algor�tm.

The dev�ce w�th ON/OFF control algor�tm, hysteres�s parameter must

be set a su�table value for your system, to avo�d too much relay

sw�tch�ng.

Vac,

Vdc,

Vdc or Vac can be appl�ed

Order�ng Informat�on

Eco LITE ( 48x48 DIN 1/16 )

D�mens�on

48x48 DIN 1/16

A

4

A

4 .

B

.

C

.

D

0 .

E

0

Outputs-1

1R

1 x Relay Output (5A@250VV at Res�st�ve Load) (NO,C)

C

2R

2 x Relay Output (5A@250VV at Res�st�ve Load) (NO,NO,C)

Supply VoltageB

10...30VZ

115VV (±%15) 50/60Hz

230VV (±%15) 50/60Hz

3

5

6

100-240VV 50/60Hz1

24VV (±%15) 50/60Hz

Customer

7

9

24VW (±%15) 50/60Hz2