Instruction manual

Table Of Contents

- Introduction

- Safety Instructions

- Specifications

- Packaged Accessories

- Tool Requirements

- ProSet® 2500 Tool Dimensions

- Common Nosepieces

- Basic Tool Operation

- ProSet® 2500 Front End Service

- Mandrel Collection System (MCS) – ProSet® 2500 MCS

- Cleaning the Collector Silencer

- Tool Assembly Torque Requirements

- ProSet® 2500/2500MCS Diagram

- ProSet® 2500 Parts List

- Hydraulic Oil Charging Procedure

- Maintenance

- Safety Data

- Troubleshooting

- EC Declaration of Conformity

- Conforms to the following standards:

- Signed: ____________________________________

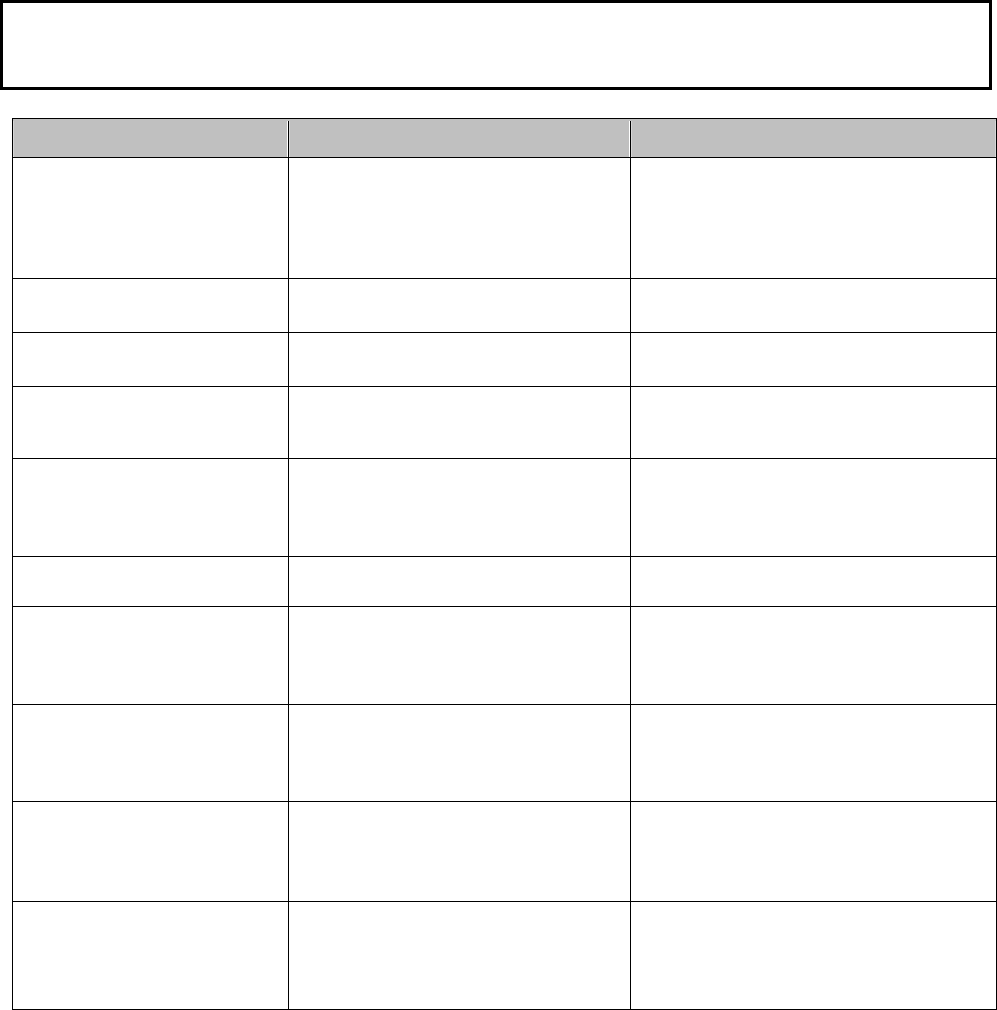

Troubleshooting

Symptom Probable Cause Remedy

Tool not connected to air supply. Connect to recommended air supply source.

OS Valve is in “OFF” position. Slide OS Valve to ON position.

TOOL FAILS TO OPERATE

Insufficient air pressure. Adjust air supply pressure.

Air pressure is too high. Adjust air supply pressure.

Tool is low on hydraulic fluid. Service tool by qualified service personnel.

Possible jam due to debris in Nose Housing. Perform “Front End Service” and check for debris

or damage.

TOOL NOT RETURNING

TOOL LOSING STROKE

Tool low on hydraulic fluid. Service tool by

qualified service personnel.

Jaws dirty or need lubrication. Clean and lube jaws.

JAWS SLIPPING ON MANDRELS

Jaws worn. Replace jaws.

Dirty Nose Housing, Jaws or Jaw Guide. Perform “Front End Service” and clean inside of

Nose Housing.

JAWS FAIL TO OPEN

Nose Housing loose. Tighten Nose Housing.

Excess hydraulic oil in tool. Service tool by qualified service personnel.

Jaws dirty or need lubrication. Perform “Front End Service” to clean and

lubricate Jaws.

MANDREL STICKING IN JAWS

Incorrect nosepiece. Install correct nosepiece.

RIVET FAILS TO INSERT INTO

NO

SEPIECE

Shear ring stuck in hole of nosepiece. Remove shear ring, check for the correct

Nosepiece and review

application parameters to

ensure proper riveting.

Rivet not fully set. Repeat stroke required, or change rivet.

RIVET MANDREL DOES NOT

BREAK

Mandrel break load requirement too high. Upgrade tool.

Insufficient air pressure. Adjust air supply pressure to recommended level.

Tool not connected to air supply. Connect to recommended air supply source.

MCS NOT WORKING

Collector not tight or missing. Check Collector.

Mandrel path blocked. Clear mandrel path.

Dirty Silencer. Clean or change Silencer.

LOW VACUUM

Collector is full of mandrels. Discard the mandrels.

Insufficient air pressure. Adjust air supply pressure.

Emhart Teknologies - 50 Shelton Technology Center, Shelton CT 06484 - Tel. (203) 924-9341 - Fax (800) 225-5614 Page 17