User Manual

Table Of Contents

- Important Safety Instructions

- SAVE THESE INSTRUCTIONS

- 1.0 Introduction

- 2.0 Startup

- 3.0 Operation with iCOM Control

- 4.0 Liebert iCOM Display Components and Functions

- Figure 2 Liebert iCOM display components

- Table 1 Keyboard icons and functions

- Figure 3 Liebert iCOM default screen symbols

- 4.1 Navigating Through the Liebert iCOM Display

- 4.2 Changing Operational Settings

- 4.3 Changing Liebert iCOM’s Display Settings

- 4.4 Graphical Data Record

- 4.5 Liebert iCOM Service Menu Icons and Legend

- 4.6 Wiring for Unit-to-Unit Communications—U2U

- 4.7 Entering Network Setup Information

- 4.8 Viewing Multiple Units with a Networked Large Display

- 5.0 Operation

- 6.0 Alarm Descriptions

- 6.1 Standard Alarms

- 6.1.1 Change Filter

- 6.1.2 Compressor Overload

- 6.1.3 High Head Pressure

- 6.1.4 High Humidity

- 6.1.5 High Humidity and Low Humidity (Simultaneously)

- 6.1.6 High Temperature

- 6.1.7 High Temperature and Low Temperature (Simultaneously)

- 6.1.8 Humidifier Problem

- 6.1.9 Loss of Air Flow

- 6.1.10 Loss of Power

- 6.1.11 Low Humidity

- 6.1.12 Low Suction Pressure

- 6.1.13 Low Temperature

- 6.1.14 Main Fan Overload

- 6.1.15 Short Cycle

- 6.2 Optional Alarms

- 6.3 Set Alarms—User Menus

- 6.1 Standard Alarms

- 7.0 Component Operation and Maintenance

- 7.1 System Testing

- 7.2 Filters

- 7.3 Blower Package

- 7.4 Refrigeration System

- 7.4.1 Suction Pressure

- 7.4.2 Discharge Pressure

- 7.4.3 Superheat

- 7.4.4 Thermostatic Expansion Valve

- 7.4.5 Hot Gas Bypass Valve—Not Available on Digital Scroll Units

- 7.4.6 Air Cooled Condenser

- 7.4.7 Water/Glycol Cooled Condensers

- 7.4.8 Motorized Ball Valve—Digital Scroll Compressor

- 7.4.9 Regulating Valve—Scroll Compressor

- 7.4.10 Drycooler Settings

- 7.4.11 Compressor Oil

- 7.5 Compressor Replacement

- 7.6 Facility Fluid and Piping Maintenance for Water and Glycol Systems

- 7.7 Humidifier

- 8.0 Troubleshooting

- Table 12 Blower troubleshooting

- Table 13 Chilled water troubleshooting

- Table 14 Compressor and refrigeration system troubleshooting

- Table 15 Dehumidification troubleshooting

- Table 16 Glycol pump troubleshooting

- Table 17 Infrared humidifier troubleshooting

- Table 18 Steam generating humidifier troubleshooting

- Table 19 Reheat troubleshooting

- 9.0 Monthly Maintenance Inspection Checklist

- 10.0 Semiannual Maintenance Inspection Checklist

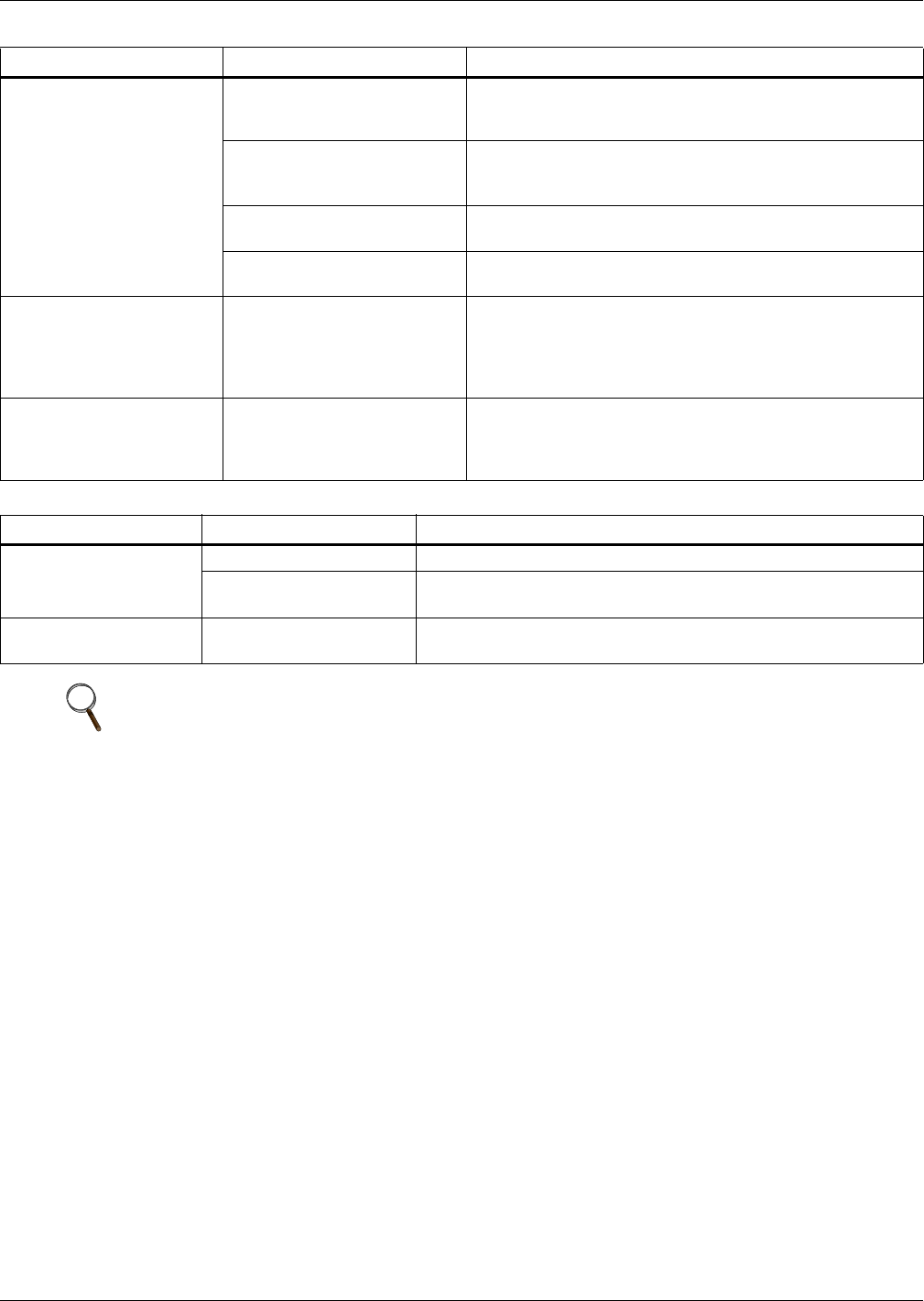

Troubleshooting

61

Excessive arcing in the

canister

Drain valve clogged or

defective

Verify that drain valve operates freely when activated. Clean

valve and replace coil or valve if defective. Flush canister

several times and replace if arcing persists.

Improper water supply

If water is commercially softened, reconnect humidifier to

raw water supply, drain canister, and restart If connected to

hot supply, reconnect to cold water.

Insufficient drain rate

Increase drain rate by adjusting % pot on circuit board

above the preset 70% to roughly 80%.

Excessive iron content in

water

Analyze iron content of water. If it exceeds 0.1 mg./l, install

a filter to remove iron from water supply.

On cold startup, canister

fills, high water alarm

activates and humidifier

fails to reach full amperage

Conductivity of water too low

Drain canister and add one Alka-Seltzer tablet to canister.

Refill. Turn the % pot to roughly 60%. Restart humidifier. If

amperage rises rapidly, it may be necessary to dilute the

water to prevent blown fuses. If it rises too slowly, add

another Alka-Seltzer tablet.

On cold startup, canister

fills, high water alarm

activates and humidifier

fails to reach full amperage

Fill solenoid not closing tightly

If humidifier returns to canister full condition, verity that the

fill solenoid closes tightly.

Table 19 Reheat troubleshooting

Symptom Possible Cause Check or Remedy

Reheat will not operate;

contactor not pulling in

Control not calling for heat Check monitor status.

Reheat safety stat open

Jumper between terminals P34-1 and P34-2. If reheat operates,

safety is open. Remove jumper. Replace safety.

Reheat not operating;

contactor pulling in

Heater burned out Turn Off power and check heater continuity with Ohm meter.

NOTE:

Reheat element sheaths and fins are manufactured with stainless steel. Regular inspections

are necessary to ensure proper cleanliness of the reheating element. Should inspection reveal

corrosion particles on the reheating element or adjoining surfaces (including ducts and

plenums), appropriate cleaning should be performed. Periodic reheating element replacement

may be required to meet specific application requirements.

Table 18 Steam generating humidifier troubleshooting (continued)

Symptom Possible Cause Check or Remedy