User Manual

Table Of Contents

- Important Safety Instructions

- SAVE THESE INSTRUCTIONS

- 1.0 Introduction

- 2.0 Startup

- 3.0 Operation with iCOM Control

- 4.0 Liebert iCOM Display Components and Functions

- Figure 2 Liebert iCOM display components

- Table 1 Keyboard icons and functions

- Figure 3 Liebert iCOM default screen symbols

- 4.1 Navigating Through the Liebert iCOM Display

- 4.2 Changing Operational Settings

- 4.3 Changing Liebert iCOM’s Display Settings

- 4.4 Graphical Data Record

- 4.5 Liebert iCOM Service Menu Icons and Legend

- 4.6 Wiring for Unit-to-Unit Communications—U2U

- 4.7 Entering Network Setup Information

- 4.8 Viewing Multiple Units with a Networked Large Display

- 5.0 Operation

- 6.0 Alarm Descriptions

- 6.1 Standard Alarms

- 6.1.1 Change Filter

- 6.1.2 Compressor Overload

- 6.1.3 High Head Pressure

- 6.1.4 High Humidity

- 6.1.5 High Humidity and Low Humidity (Simultaneously)

- 6.1.6 High Temperature

- 6.1.7 High Temperature and Low Temperature (Simultaneously)

- 6.1.8 Humidifier Problem

- 6.1.9 Loss of Air Flow

- 6.1.10 Loss of Power

- 6.1.11 Low Humidity

- 6.1.12 Low Suction Pressure

- 6.1.13 Low Temperature

- 6.1.14 Main Fan Overload

- 6.1.15 Short Cycle

- 6.2 Optional Alarms

- 6.3 Set Alarms—User Menus

- 6.1 Standard Alarms

- 7.0 Component Operation and Maintenance

- 7.1 System Testing

- 7.2 Filters

- 7.3 Blower Package

- 7.4 Refrigeration System

- 7.4.1 Suction Pressure

- 7.4.2 Discharge Pressure

- 7.4.3 Superheat

- 7.4.4 Thermostatic Expansion Valve

- 7.4.5 Hot Gas Bypass Valve—Not Available on Digital Scroll Units

- 7.4.6 Air Cooled Condenser

- 7.4.7 Water/Glycol Cooled Condensers

- 7.4.8 Motorized Ball Valve—Digital Scroll Compressor

- 7.4.9 Regulating Valve—Scroll Compressor

- 7.4.10 Drycooler Settings

- 7.4.11 Compressor Oil

- 7.5 Compressor Replacement

- 7.6 Facility Fluid and Piping Maintenance for Water and Glycol Systems

- 7.7 Humidifier

- 8.0 Troubleshooting

- Table 12 Blower troubleshooting

- Table 13 Chilled water troubleshooting

- Table 14 Compressor and refrigeration system troubleshooting

- Table 15 Dehumidification troubleshooting

- Table 16 Glycol pump troubleshooting

- Table 17 Infrared humidifier troubleshooting

- Table 18 Steam generating humidifier troubleshooting

- Table 19 Reheat troubleshooting

- 9.0 Monthly Maintenance Inspection Checklist

- 10.0 Semiannual Maintenance Inspection Checklist

Troubleshooting

60

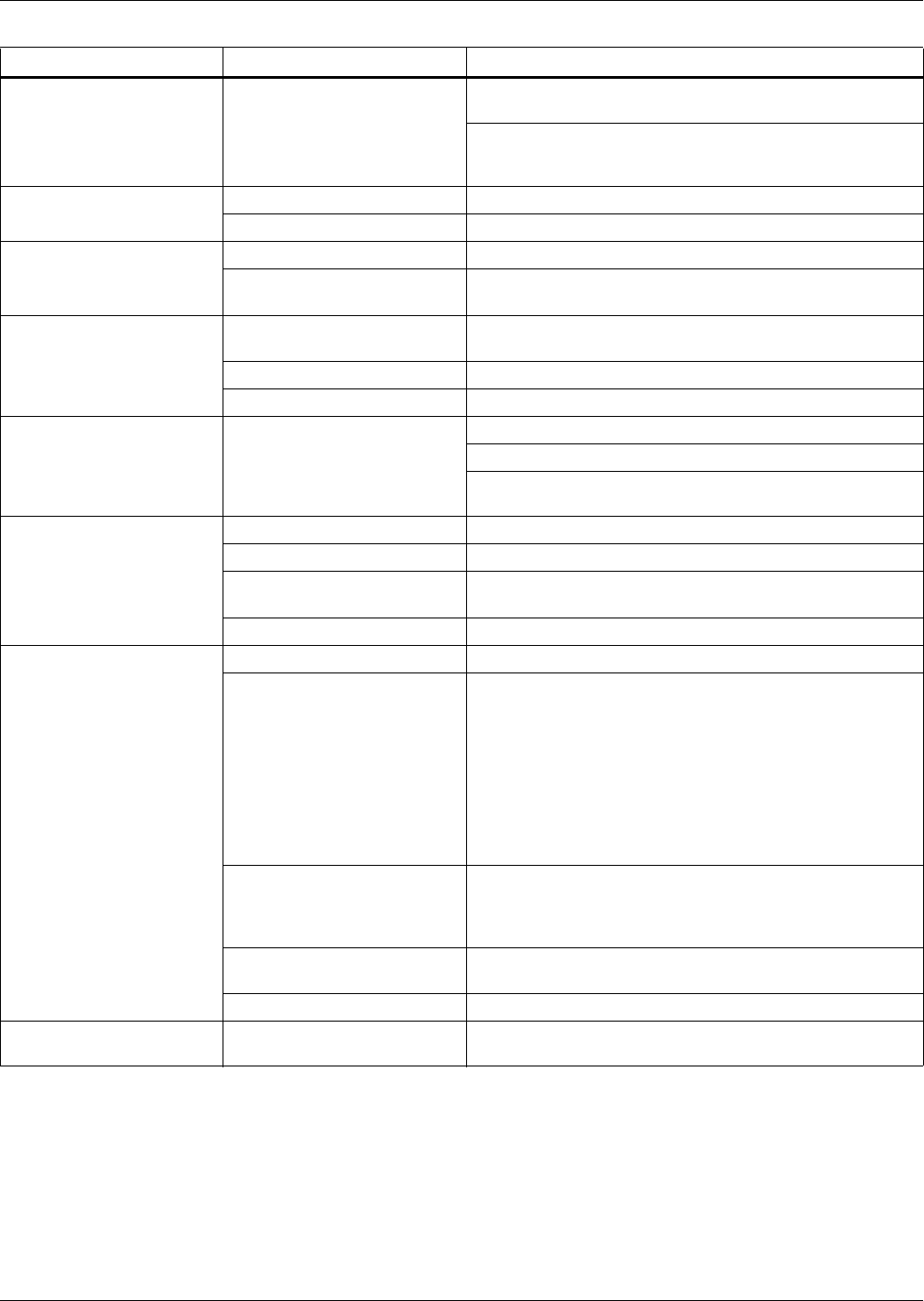

Table 18 Steam generating humidifier troubleshooting

Symptom Possible Cause Check or Remedy

False canister full indication Foaming

Check drain valve to ensure that it drains freely. Check and

replace if defective.

Check water supply. If commercially softened, reconnect to

raw water supply. If connected to hot water reconnect to

cold water.

Main 24 VAC fuse or circuit

breaker trips

Shorts or loose connections Check the wiring connections of the 24 VAC circuit.

Faulty circuit board Replace the circuit board.

Main fuses blow

approximately 15 seconds

after unit is activated

Faulty solenoid Check for magnetic field at coil.

Conductivity too high

Check amp draw of humidifier on startup. If it exceeds rated

amps, increase setting of the % pot on the circuit board

Main fuses blow when

drain valve is activated.

Mineral deposits obstruct

drain valve

Check drain valve for obstructions and clean if necessary.

Faulty solenoid Check for magnetic field at coil.

Faulty circuit board Replace circuit board.

Unit On, humidifier will not

operate

Humidifier not receiving power

Verify that RUN/DRAIN switch is in the RUN position.

Check fuses or CBs and replace or reset if necessary.

Make sure molex connector is securely plugged into circuit

board and that no wires are loose.

Contactor pulled in, but no

water enters canister

No water available to unit Check external shutoff valves.

Clogged fill line strainer Clean or replace fill line strainer.

Wiring breaks or loose

connections

Check for faulty wiring and loose connections.

Faulty circuit board Replace circuit board.

Water enters canister, but

canister full circuit activates

at a low water level

Foaming Check drain valve and water supply.

Canister interface connections

incorrect

Check connection on component plate in humidifier cabinet.

Terminal #1 on the square block interface device must be

connected to L2 of the power terminal block. L2 must also

be connected to the electrode closest to the steam outlet

port.

Verify that the red wire from Terminal #2 on the interface

connects to the red top terminal on the canister. This is the

one farthest from the steam outlet port and is the high water

sensor probe.

Full isolation has broken down

Remove red canister full wire from canister. If normal

operation resumes, canister must be replaced. Remove the

wire from Terminal #3 on the interface. If normal operation

resumes, canister full interface must be replaced.

Drain assembly not operating

freely

Check and replace coil or valve if necessary.

Faulty circuit board Replace circuit board

Canister fills but overflows

Canister full circuit does not

activate

Check wiring of canister full interface. Replace circuit board.