User Manual

Table Of Contents

- Important Safety Instructions

- SAVE THESE INSTRUCTIONS

- 1.0 Introduction

- 2.0 Startup

- 3.0 Operation with iCOM Control

- 4.0 Liebert iCOM Display Components and Functions

- Figure 2 Liebert iCOM display components

- Table 1 Keyboard icons and functions

- Figure 3 Liebert iCOM default screen symbols

- 4.1 Navigating Through the Liebert iCOM Display

- 4.2 Changing Operational Settings

- 4.3 Changing Liebert iCOM’s Display Settings

- 4.4 Graphical Data Record

- 4.5 Liebert iCOM Service Menu Icons and Legend

- 4.6 Wiring for Unit-to-Unit Communications—U2U

- 4.7 Entering Network Setup Information

- 4.8 Viewing Multiple Units with a Networked Large Display

- 5.0 Operation

- 6.0 Alarm Descriptions

- 6.1 Standard Alarms

- 6.1.1 Change Filter

- 6.1.2 Compressor Overload

- 6.1.3 High Head Pressure

- 6.1.4 High Humidity

- 6.1.5 High Humidity and Low Humidity (Simultaneously)

- 6.1.6 High Temperature

- 6.1.7 High Temperature and Low Temperature (Simultaneously)

- 6.1.8 Humidifier Problem

- 6.1.9 Loss of Air Flow

- 6.1.10 Loss of Power

- 6.1.11 Low Humidity

- 6.1.12 Low Suction Pressure

- 6.1.13 Low Temperature

- 6.1.14 Main Fan Overload

- 6.1.15 Short Cycle

- 6.2 Optional Alarms

- 6.3 Set Alarms—User Menus

- 6.1 Standard Alarms

- 7.0 Component Operation and Maintenance

- 7.1 System Testing

- 7.2 Filters

- 7.3 Blower Package

- 7.4 Refrigeration System

- 7.4.1 Suction Pressure

- 7.4.2 Discharge Pressure

- 7.4.3 Superheat

- 7.4.4 Thermostatic Expansion Valve

- 7.4.5 Hot Gas Bypass Valve—Not Available on Digital Scroll Units

- 7.4.6 Air Cooled Condenser

- 7.4.7 Water/Glycol Cooled Condensers

- 7.4.8 Motorized Ball Valve—Digital Scroll Compressor

- 7.4.9 Regulating Valve—Scroll Compressor

- 7.4.10 Drycooler Settings

- 7.4.11 Compressor Oil

- 7.5 Compressor Replacement

- 7.6 Facility Fluid and Piping Maintenance for Water and Glycol Systems

- 7.7 Humidifier

- 8.0 Troubleshooting

- Table 12 Blower troubleshooting

- Table 13 Chilled water troubleshooting

- Table 14 Compressor and refrigeration system troubleshooting

- Table 15 Dehumidification troubleshooting

- Table 16 Glycol pump troubleshooting

- Table 17 Infrared humidifier troubleshooting

- Table 18 Steam generating humidifier troubleshooting

- Table 19 Reheat troubleshooting

- 9.0 Monthly Maintenance Inspection Checklist

- 10.0 Semiannual Maintenance Inspection Checklist

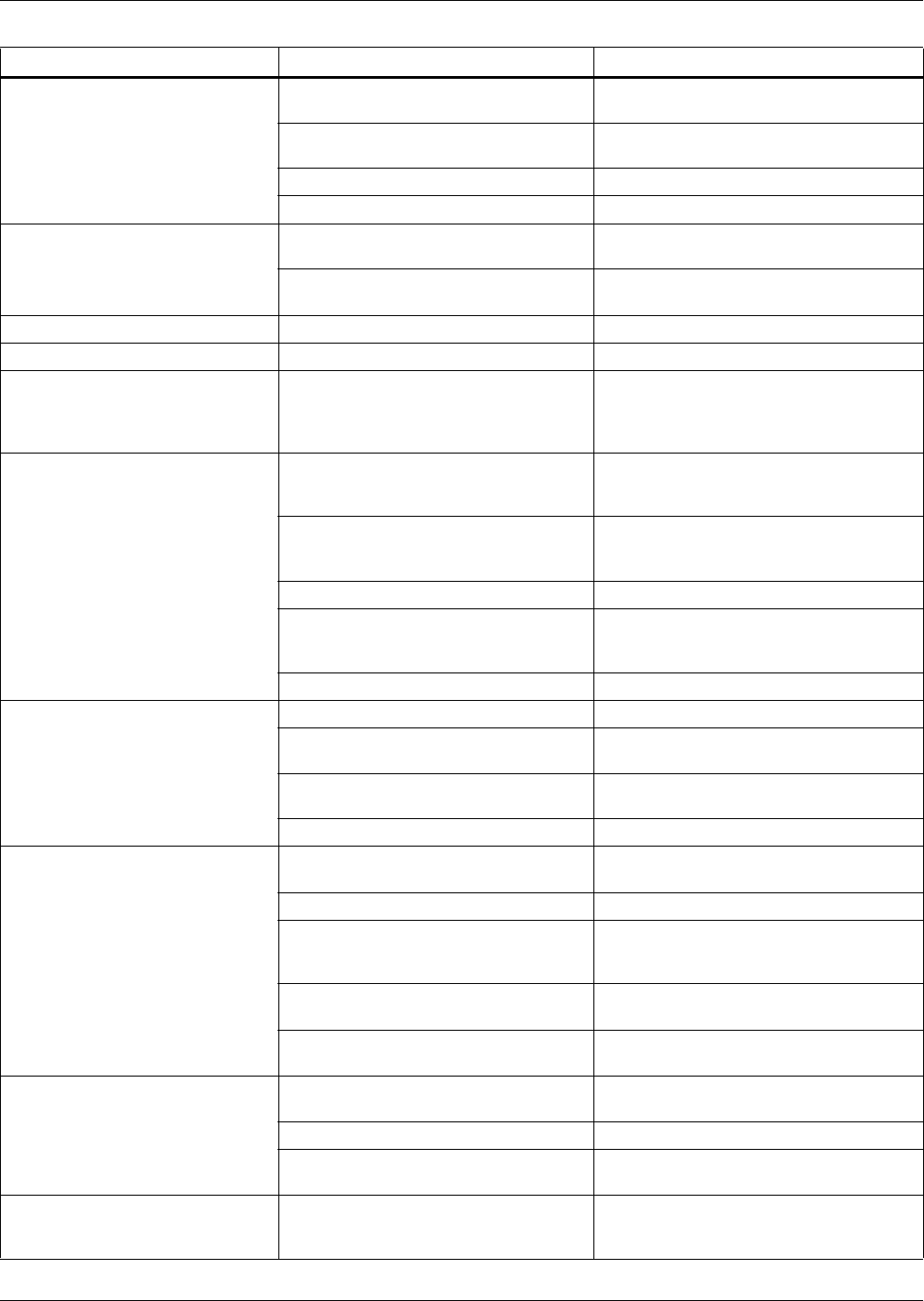

Troubleshooting

58

Flooding

Defective or improperly set expansion

valve

Increase superheat or replace valve

Evaporator fan motor or belt

Correct problem or replace fan motor and/

or belts.

Low condensing pressure Check head pressure control device

Slipping belts Inspect and adjust

Low compressor capacity or

inability to pull down system

Compressor rotation in reverse

direction.

Check for proper power phase wiring to

unit and to compressor motor.

Leaking liquid line solenoid valve or dirt

in valve

Replace valve if clean; clean out valve if

dirty.

Compressor noisy Loose compressor or piping support Tighten clamps.

Pipe rattle Loose pipe connections Check pipe connections

Compressor running hot Compression ratio too high

Check setting of high and low pressure

switches. Check condenser -- is it

plugged? Check that all evaporator and

condenser fans are operating properly.

Compressor cycles intermittently

Low-pressure switch erratic in operation

Check tubing to switch to see if clogged or

crimped. Check for proper switch

operation.

Insufficient refrigerant in system

Check for leaks, fix, and add refrigerant on

air cooled unit. Evacuate and recharge

water/glycol unit.

Suction service valve closed Open valve.

Insufficient fluid flowing through

condenser or clogged condenser, or

dirty air cooled condenser coils

Adjust fluid regulating valve to condenser.

Flush the condenser.

Discharge service valve not fully open Open valve

Compressor cycles continually

Faulty low pressure switch Repair or replace.

Dirt or restriction in tubing to pressure

stat

Check and clean tubing.

Defective liquid line solenoid valve

Check valve and solenoid operator;

replace if necessary.

Plugged filter-drier Replace filter.

Compressor motor protectors

tripping or cycling

High discharge pressure

Check for loss of condenser water or

blocked condenser fan or coil.

Defective overload relay Replace.

High suction temperature

Reduce suction temperature by expansion

valve adjustment or provide

desuperheating.

Loose power or control circuit wiring

connection

Check all power and control circuit

connections.

Defective motor

Check for motor ground or short. Replace

compressor, if either condition is found.

Compressor cycles on locked rotor

Low line voltage

Check line voltage and determine location

of voltage drop.

Compressor motor defective Check for motor winding short or ground.

Single phasing

Check voltage across all 3 legs at

contactor. Correct source problem.

Motor burnout

Check control panel for welded

contactor contacts or welded overload

contacts

Replace defective components

Table 14 Compressor and refrigeration system troubleshooting (continued)

Symptom Possible Cause Check or Remedy