User Manual

Table Of Contents

- Important Safety Instructions

- SAVE THESE INSTRUCTIONS

- 1.0 Introduction

- 2.0 Startup

- 3.0 Operation with iCOM Control

- 4.0 Liebert iCOM Display Components and Functions

- Figure 2 Liebert iCOM display components

- Table 1 Keyboard icons and functions

- Figure 3 Liebert iCOM default screen symbols

- 4.1 Navigating Through the Liebert iCOM Display

- 4.2 Changing Operational Settings

- 4.3 Changing Liebert iCOM’s Display Settings

- 4.4 Graphical Data Record

- 4.5 Liebert iCOM Service Menu Icons and Legend

- 4.6 Wiring for Unit-to-Unit Communications—U2U

- 4.7 Entering Network Setup Information

- 4.8 Viewing Multiple Units with a Networked Large Display

- 5.0 Operation

- 6.0 Alarm Descriptions

- 6.1 Standard Alarms

- 6.1.1 Change Filter

- 6.1.2 Compressor Overload

- 6.1.3 High Head Pressure

- 6.1.4 High Humidity

- 6.1.5 High Humidity and Low Humidity (Simultaneously)

- 6.1.6 High Temperature

- 6.1.7 High Temperature and Low Temperature (Simultaneously)

- 6.1.8 Humidifier Problem

- 6.1.9 Loss of Air Flow

- 6.1.10 Loss of Power

- 6.1.11 Low Humidity

- 6.1.12 Low Suction Pressure

- 6.1.13 Low Temperature

- 6.1.14 Main Fan Overload

- 6.1.15 Short Cycle

- 6.2 Optional Alarms

- 6.3 Set Alarms—User Menus

- 6.1 Standard Alarms

- 7.0 Component Operation and Maintenance

- 7.1 System Testing

- 7.2 Filters

- 7.3 Blower Package

- 7.4 Refrigeration System

- 7.4.1 Suction Pressure

- 7.4.2 Discharge Pressure

- 7.4.3 Superheat

- 7.4.4 Thermostatic Expansion Valve

- 7.4.5 Hot Gas Bypass Valve—Not Available on Digital Scroll Units

- 7.4.6 Air Cooled Condenser

- 7.4.7 Water/Glycol Cooled Condensers

- 7.4.8 Motorized Ball Valve—Digital Scroll Compressor

- 7.4.9 Regulating Valve—Scroll Compressor

- 7.4.10 Drycooler Settings

- 7.4.11 Compressor Oil

- 7.5 Compressor Replacement

- 7.6 Facility Fluid and Piping Maintenance for Water and Glycol Systems

- 7.7 Humidifier

- 8.0 Troubleshooting

- Table 12 Blower troubleshooting

- Table 13 Chilled water troubleshooting

- Table 14 Compressor and refrigeration system troubleshooting

- Table 15 Dehumidification troubleshooting

- Table 16 Glycol pump troubleshooting

- Table 17 Infrared humidifier troubleshooting

- Table 18 Steam generating humidifier troubleshooting

- Table 19 Reheat troubleshooting

- 9.0 Monthly Maintenance Inspection Checklist

- 10.0 Semiannual Maintenance Inspection Checklist

Troubleshooting

57

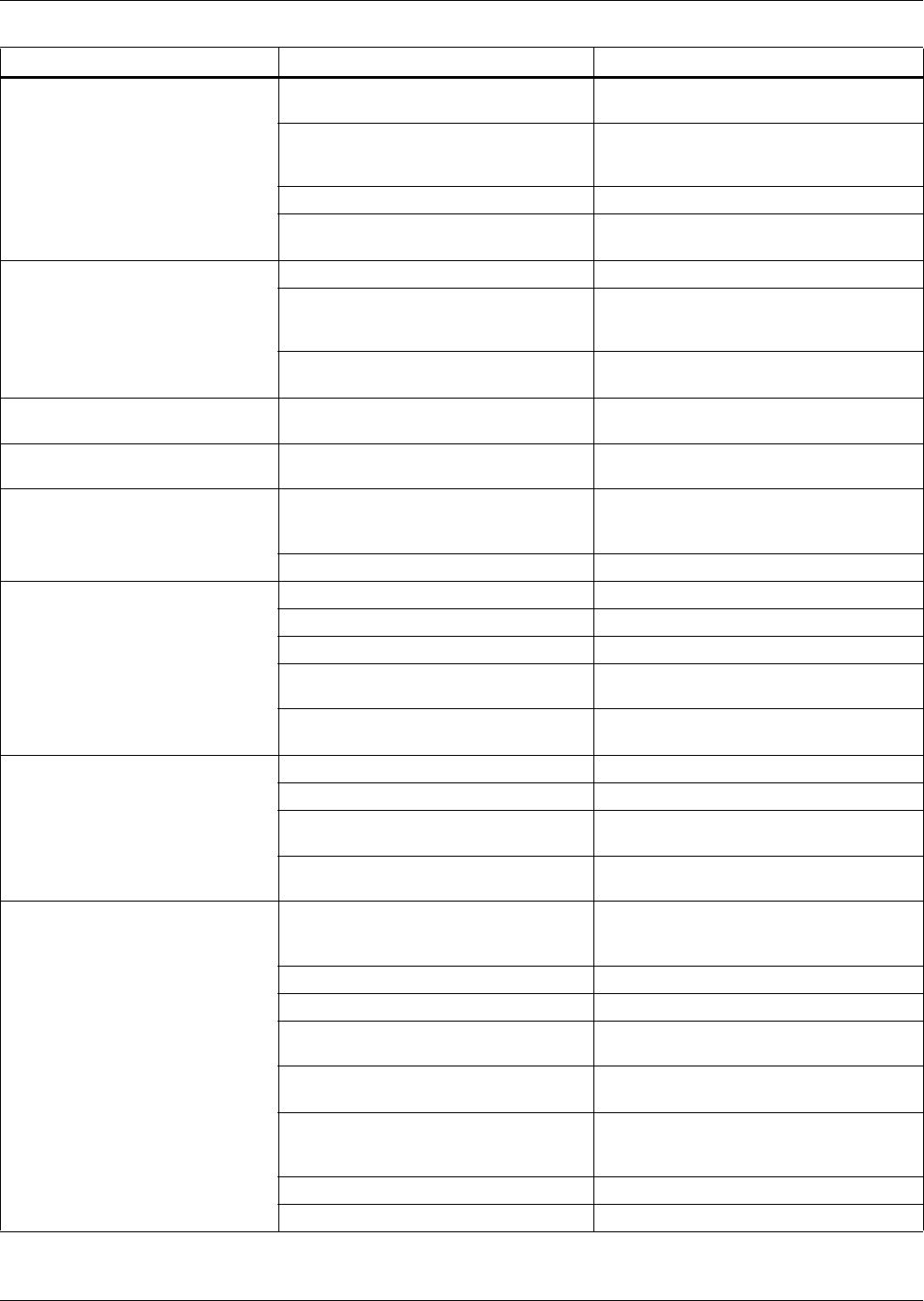

Table 14 Compressor and refrigeration system troubleshooting

Symptom Possible Cause Check or Remedy

Compressor will not start

Power Off

Check main switch, fuses or CBs and

wiring

Current overload open

Re-set units with overload option

manually. Allow compressor to cool for

internal overloads to reset.

Loose electrical connections Tighten connections

Compressor motor burned out

Check and replace compressor if

defective.

Compressor will not operate,

contactor not pulling in

No call for cooling Check monitor status.

Solenoid valve not energizing

Hold screwdriver over solenoid and check

for magnetic field. This indicates solenoid

is energized.

Low pressure switch not making contact

Check gas pressure - manually energize

low pressure switch.

Compressor will not operate,

contact not pulling in

High pressure switch open

Reset switch. Refer to other refrigeration

troubleshooting suggestions.

Compressor contactor pulled in but

compressor will not operate

Blown fuse or tripped CB

Check for line voltage after fuses or CBs,

and after contactors.

Compressor runs for three minutes

then stops; contactor drops out.

Low pressure switch not closing

Check for low gas pressure. Compressor

is running on Positive Start Kit (air cooled

systems only)

Liquid line solenoid valve not opening Check magnetic field to see if energized.

High discharge pressure

Dirty condenser or drycooler fins Clean coil.

Condenser equipment not operating Check operation.

High refrigerant charge Check refrigerant charge.

Hot gas bypass valve adjusted

improperly

Adjust properly.

Water regulating valve adjusted

improperly

Adjust properly.

Low discharge pressure

Excessive fluid flow through condenser Adjust fluid regulating valve

Suction service valve partially closed Open the valve.

Faulty head pressure control valve or

condenser fan speed control

Replace if defective.

Compressor rotation in reverse direction

Check for proper power phase wiring to

unit and to compressor motor.

Low suction pressure

Insufficient refrigerant in system

Check for leaks, repair, and add

refrigerant for air cooled. Evacuate and

recharge for water/glycol unit.

Dirty air filters Change filters.

Plugged filter-drier Replace filter.

Improper superheat adjustment

Reset expansion valve for 10-15

°F

(6-8°C)

Defective expansion valve sensing

element

Replace element

Poor air distribution

Check duct work for closed dampers.

Check for under-floor restrictions at or

near the unit.

Low condensing pressure Check head pressure control device.

Slipping belts Inspect and adjust