User Manual

Table Of Contents

- Important Safety Instructions

- SAVE THESE INSTRUCTIONS

- 1.0 Introduction

- 2.0 Startup

- 3.0 Operation with iCOM Control

- 4.0 Liebert iCOM Display Components and Functions

- Figure 2 Liebert iCOM display components

- Table 1 Keyboard icons and functions

- Figure 3 Liebert iCOM default screen symbols

- 4.1 Navigating Through the Liebert iCOM Display

- 4.2 Changing Operational Settings

- 4.3 Changing Liebert iCOM’s Display Settings

- 4.4 Graphical Data Record

- 4.5 Liebert iCOM Service Menu Icons and Legend

- 4.6 Wiring for Unit-to-Unit Communications—U2U

- 4.7 Entering Network Setup Information

- 4.8 Viewing Multiple Units with a Networked Large Display

- 5.0 Operation

- 6.0 Alarm Descriptions

- 6.1 Standard Alarms

- 6.1.1 Change Filter

- 6.1.2 Compressor Overload

- 6.1.3 High Head Pressure

- 6.1.4 High Humidity

- 6.1.5 High Humidity and Low Humidity (Simultaneously)

- 6.1.6 High Temperature

- 6.1.7 High Temperature and Low Temperature (Simultaneously)

- 6.1.8 Humidifier Problem

- 6.1.9 Loss of Air Flow

- 6.1.10 Loss of Power

- 6.1.11 Low Humidity

- 6.1.12 Low Suction Pressure

- 6.1.13 Low Temperature

- 6.1.14 Main Fan Overload

- 6.1.15 Short Cycle

- 6.2 Optional Alarms

- 6.3 Set Alarms—User Menus

- 6.1 Standard Alarms

- 7.0 Component Operation and Maintenance

- 7.1 System Testing

- 7.2 Filters

- 7.3 Blower Package

- 7.4 Refrigeration System

- 7.4.1 Suction Pressure

- 7.4.2 Discharge Pressure

- 7.4.3 Superheat

- 7.4.4 Thermostatic Expansion Valve

- 7.4.5 Hot Gas Bypass Valve—Not Available on Digital Scroll Units

- 7.4.6 Air Cooled Condenser

- 7.4.7 Water/Glycol Cooled Condensers

- 7.4.8 Motorized Ball Valve—Digital Scroll Compressor

- 7.4.9 Regulating Valve—Scroll Compressor

- 7.4.10 Drycooler Settings

- 7.4.11 Compressor Oil

- 7.5 Compressor Replacement

- 7.6 Facility Fluid and Piping Maintenance for Water and Glycol Systems

- 7.7 Humidifier

- 8.0 Troubleshooting

- Table 12 Blower troubleshooting

- Table 13 Chilled water troubleshooting

- Table 14 Compressor and refrigeration system troubleshooting

- Table 15 Dehumidification troubleshooting

- Table 16 Glycol pump troubleshooting

- Table 17 Infrared humidifier troubleshooting

- Table 18 Steam generating humidifier troubleshooting

- Table 19 Reheat troubleshooting

- 9.0 Monthly Maintenance Inspection Checklist

- 10.0 Semiannual Maintenance Inspection Checklist

Component Operation and Maintenance

54

Replacing the Canister

Over a period of operation, the humidifier electrodes become coated with mineral solids. This coating

insulates the electrodes and decreases the current flow. To maintain humidifier capacity, the water

level slowly rises to expose fresh electrode. Eventually, the entire electrode becomes coated and the

water level reaches the top. At this point, the canister full alarm is activated and the output begins to

fall. When this happens, it is necessary to replace the full canister.

To replace the canister:

1. Turn the humidifier Off by lowering the humidity setpoint below the ambient humidity level.

Record the original setpoint.

2. Place the RUN/DRAIN switch in the DRAIN position to drain the water from the canister.

3. Return the RUN/DRAIN switch to the RUN position after the canister has drained.

4. Turn Off the power at the main unit.

5. Remove the cover from the humidifier cabinet.

6. Locate the power wires to the steam canister. They are connected to the canister with 1/4" quick

connects. Make note of the wiring configuration before removing any wires. Refer to the schematic

on the unit. Slide the rubber boot back to expose the connections. Remove the three power wires

and the two canister full wires. Do not loosen the screws that secure the electrodes.

7. Loosen the steam outlet hose clamp and slide the steam hose away from the canister top fitting.

8. The canister is now ready to be removed. Pull the canister straight up and out of the cabinet

toward you.

9. Replace the canister with the part indicated in Table 11.

10. Replace the canister by reversing the above procedure. Make special note of the following:

!

WARNING

Risk of electric shock. Can cause injury or death.

To avoid a shock hazard, all power to the unit must be disconnected before proceeding with

the canister replacement procedure.

!

CAUTION

Risk of contact with hot surfaces. Can cause injury.

The canister and steam hose may be hot. Allow sufficient time for them to cool before working

within the unit cabinet. Use extreme caution and wear protective gloves and arm protection

when working on or near the canister or steam hose.

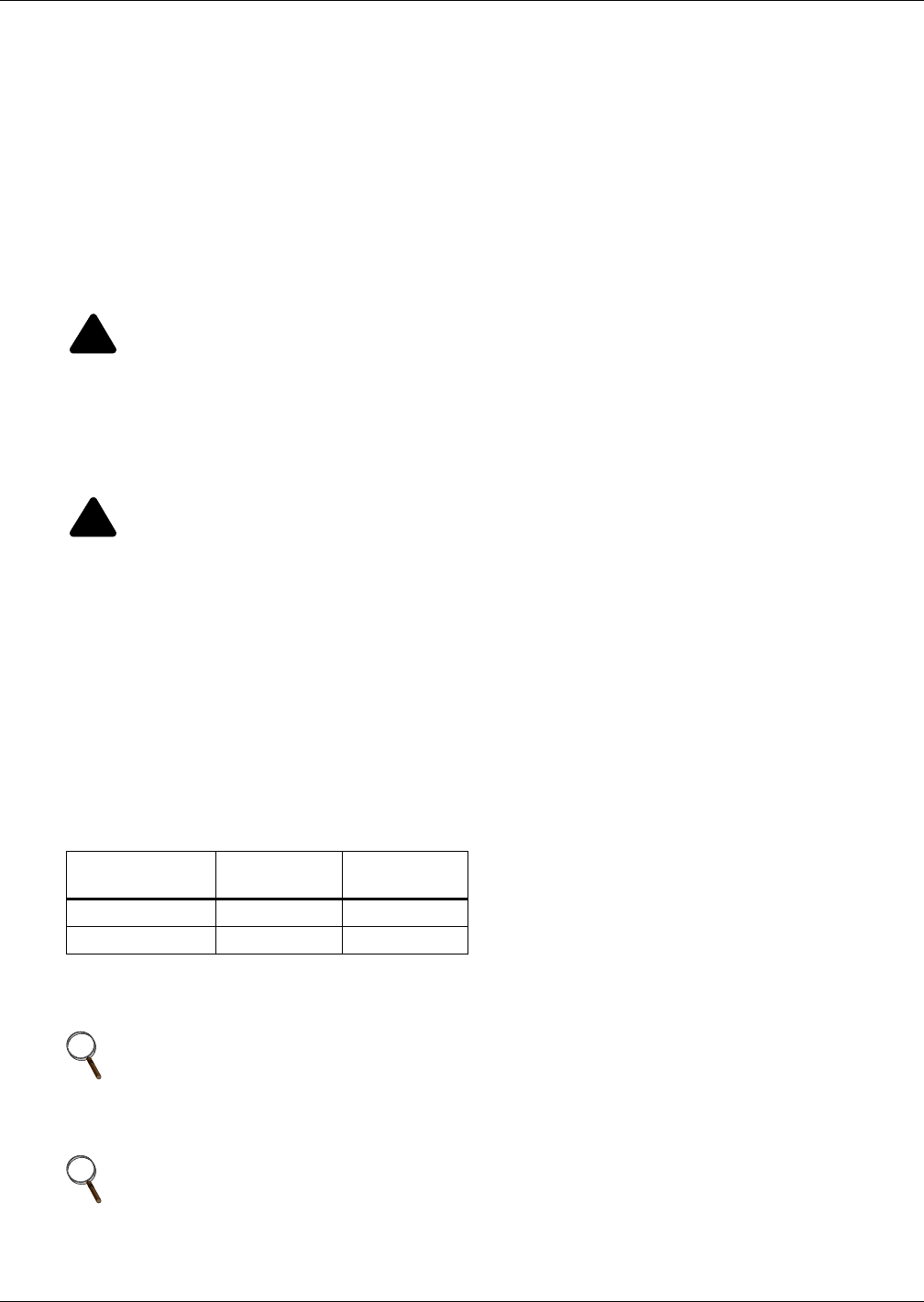

Table 11 Humidifier canister part numbers

Part

Number Voltage

Capacity

lb/hr (kg/hr)

136798P1 200-460* 11 (5)

136798P2 380-575 11 (5)

* Can operate on 575V unit with transformer

NOTE

When replacing the canister:

1. Make sure the two “O” rings are lubricated and properly seated on the bottom neck.

2. Always check the fill and drain solenoids for proper operation.

NOTE

When replacing the wiring, connect the red wire from Terminal #1 on the interface to the red

top terminal on the canister. It is in the middle of a group of three terminals. The black wire

from Terminal #2 on the interface connects to the power terminal farthest from the red

terminal/wire. The power wire to this terminal is routed through the current sensing coil.