Data Sheet

YD and YS Valves

D100031X012

Product Bulletin

51.1:YD

June 2014

4

ENVIRO-SEAL Packing System Specifications

Applicable Stem Diameters

J 9.5 mm (3/8 inches), J 12.7 (1/2), J 19.1 (3/4),

and

J 25.4 (1) diameter valve stems

Maximum Pressure/Temperature Limits

(1)

To Meet the EPA Fugitiv e Emission Standard of 100

PPM

(2)

For ENVIRO-SEAL PTFE and ENVIRO-SEAL Duplex packing

systems: full CL300 up to 232_C(450_F)

For ENVIRO-SEAL Graphite ULF packing system: 104 bar

(1500 psig) at 316_C(600_F)

Construction Materials

PTFE Packing Systems

Packing Ring and Lower Wiper: PTFE V-ring

(3)

Male and Female Adaptor Rings: Carbon-filled PTFE

V-ring

Anti-Extrusion Washer: Filled PTFE

Lantern Ring: S31600 (316 stainless steel)

Spring:

J 17-7PH stainless steel or J N06600

Packing Box Flange: S31600

Packing Follower: S31600 lined with carbon-filled PTFE

Packing Box Studs: SA193-B8M Class 2

Packing Box Nuts: S31600

Graphite ULF Packing Systems

Packing Ring: Graphite rings

Spring:

J 17-7PH stainless steel or J N06600

Packing Box Flange: S31600

Packing Follower: S31600 lined with carbon-filled PTFE

Packing Box Studs: SA193-B8M Class 2

Packing Box Nuts: S31600

1. Refer to the valve specifications in this bulletin for pressure/temperature limits of valve parts. Do not exceed the press ure/temperature rating of the valve. Do not exceed any applicable code

or standard limitation.

2. The Environmental Protection Agency (EPA) has set a limit of 100 parts per million (ppm) for fugitive emissions from a valve in selected VOC (VolatileOrganicCompound)services.

3. In vacuum service, reversing the ENVIRO-SEAL PTFE packing rings is not necessary.

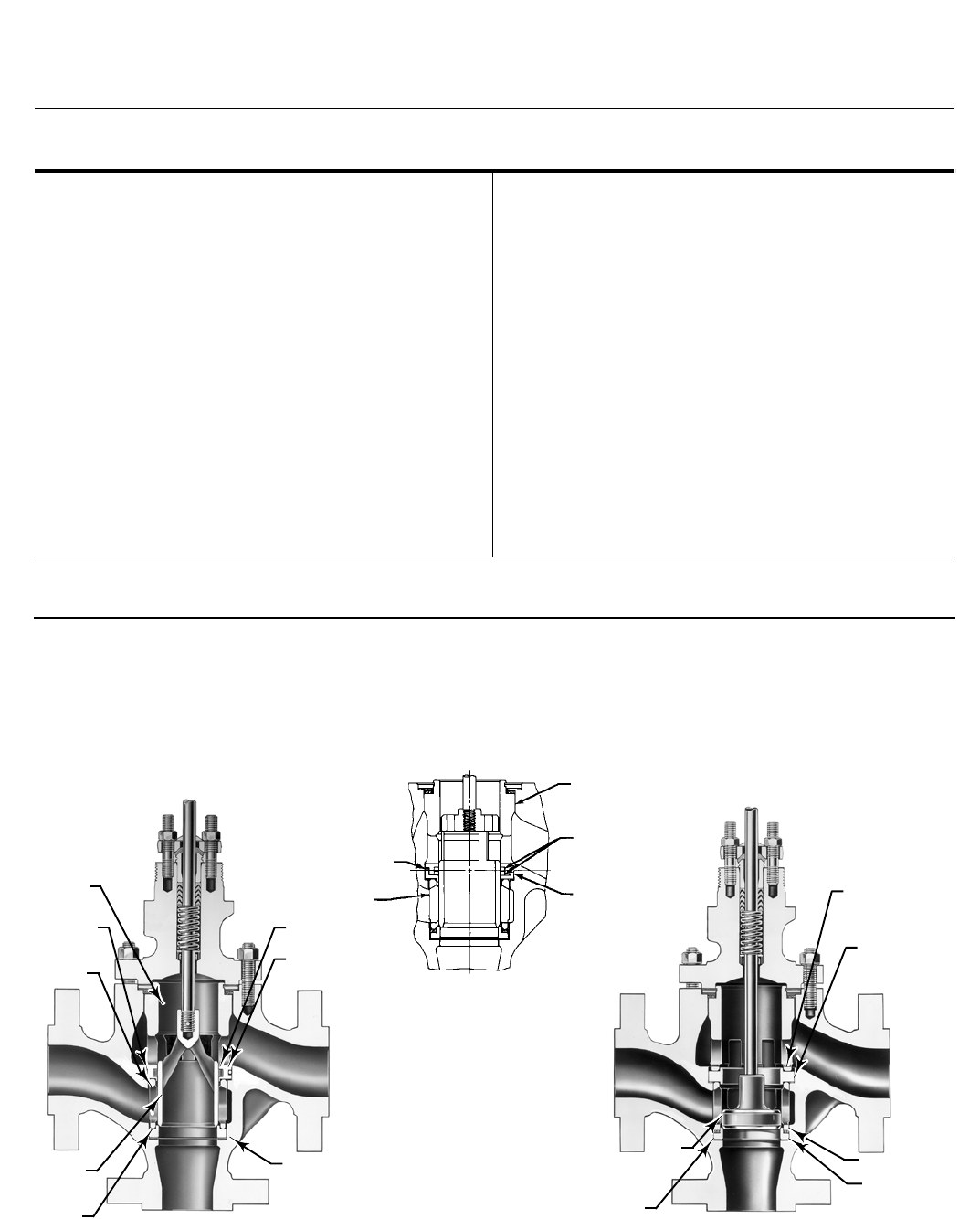

Figure 1. Construction Details

CAGE

O-RING

LOWER

CAGE

VALVE

PLUG

SEAT

RING

LOWER

SEAT

RING

VALVE

PLUG

UPPER

CAGE

REVERSIBLE

UPPER

SEAT RING

SEAL

RING

BACKUP

RING

SEAT RING

GASKET

RETAINING

RING GASKETS

LOWER

CAGE

UPPER

CAGE

VALVE

PLUG

SEALS

RETAINING

RING

UPPER

SEAT RING

GASKET

LOWER

SEAT RING

GASKET

STANDARD YD

DETAIL OF HIGH TEMPERATURE

YD TRIM

YS

W9045-1

40A3551-C

A1891-1

W9046-1

SPRING