Data Sheet

YD and YS Valves

D100031X012

Product Bulletin

51.1:YD

June 2014

22

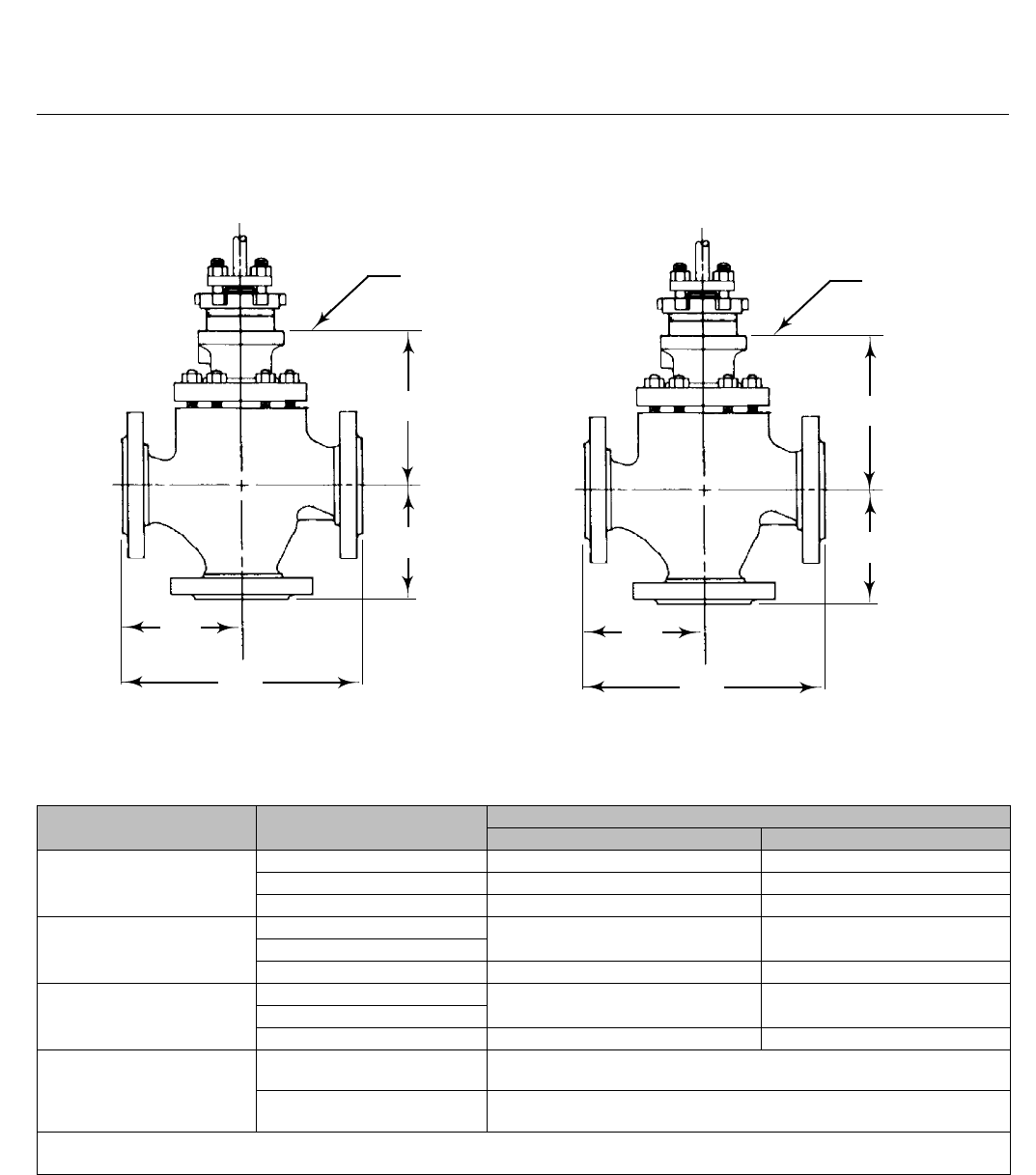

Figure 8. Fisher YD and YS Dimensions (also see table 9)

D

A2

A

MATCH LINE

FOR ACTUATOR

A2

A1893A-1

D

C

A

MATCH LINE

FOR ACTUATOR

A2

A1893A-1

NPS8YDandYSHIGHTEMPERATURE

Table 11. Bonnet Selection Guidelines

BONNET STYLE PACKING MATERIAL

IN-BODY PROCESS TEMPERATURE LIMITS

(1)

_C _F

Plain (standard)

PTFE V-ring -18 to 232 0 to 450

PTFE/composition -18 to 232 0 to 450

Graphite ribbon/filament -18 to max shown in table 5 0 to max shown in table 5

Style 1 cast extension

PTFE V-ring

-46 to 427 -50 to 800

PTFE/composition

Graphite ribbon/filament -46 to max shown in table 5 -50tomaxshownintable5

Style 2 cast extension

PTFE V-ring

-101 to 427 -150 to 800

PTFE/composition

Graphite ribbon/filament -101 to max shown in table 5 -150 to max shown in table 5

ENVIRO-SEAL bellows seal

bonnet

PTFE

For exceptional stem sealing capabilities. See bulletin 59.1:070, ENVIRO-SEAL

Bellows Seal Bonnets, for pressure/temperature ratings.

Graphite

For exceptional stem sealing capabilities. See bulletin 59.1:070, ENVIRO-SEAL

Bellows Seal Bonnets, for pressure/temperature ratings.

1. These in-body process temperatures assume an outside, ambient temperature of 21_C(70_F) and no insulation on the bonnet. When using any packing at low process temperatures, a cast

extension bonnet may have to be used to prevent the packing damage which could result from the formation of valve stem frost. Material selection for trim and other components will also be

limiting factors.