Data Sheet

YD and YS Valves

D100031X012

Product Bulletin

51.1:YD

June 2014

10

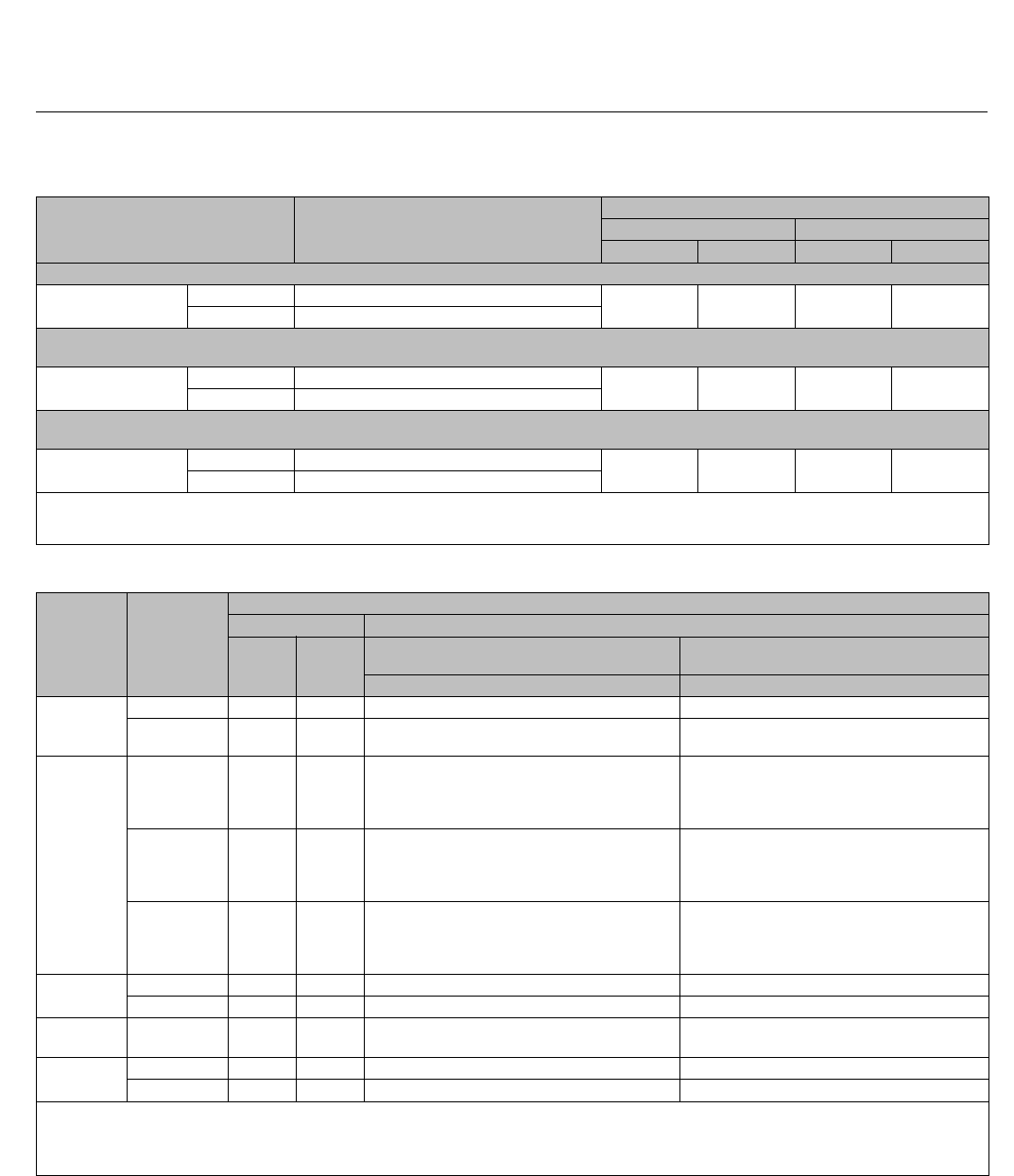

Table 4. Bolting Materials and Temperature Limits for Bolting Compliance with NACE Specification MR0175-2002,

MR0157/ISO 15156, and MR0103

VALVE BODY MATERIAL BOLTING MATERIAL

TEMPERATURE CAPABILITIES

_C _F

Min Max Min Max

NACE MR0175-2002, MR0157/ISO 15156, and MR0103 (non-exposed bolting) (Standard)

WCC and CF8M

(316 SST)

Studs Steel SA-193-B7

-48

(3)

427 -55

(3)

800

Nuts Steel SA-194-2H

NACE MR0175-2002 (exposed bolting) (Optional)

No Derating of Valve Required

WCC and CF8M

Studs Steel SA-564-630 (H1150 dbl

(1)

)

-46

(3)

343 -50

(3)

650

Nuts Steel SA-194-2HM

NACE MR0175-2002, MR0157/ISO 15156, and MR0103 (exposed bolting) (Optional)

Requires Derating of Valve

(2)

When These Body-to-Body Bolting Materials are Used

WCC and CF8M

Studs Steel SA-193-B7M

-48

(3)

427 -55

(3)

800

Nuts Steel SA-194-2HM

1. Special heat treating required.

2. Derating is not required for CL300 valves. Derating may be required for valves rated at CL600. Contact your Emerson Process Management sales office for assistance in determining the

derating of valves when these body-to-bonnet bolting materials are used.

3. WCC is limited to -29_C(-20_F).

Table 5. Valve Body-Trim Temperature Capabilities

(1)

VALVE

BODY

MATERIAL

TRIM

NUMBER

FROM

TABLE 2

TEMPERATURE

(2)

Minimum Maximum

_C _F

Standard YD

YS and

High-Temperature YD

_C(_F) _C(_F)

Cast Iron

(3)

1 -73 - 100 232 (450) 232 (450)

2

(2)

and 2A -73 - 100

NPS 1-1/2 to 3: 232 (450)

NPS 4 to 6: 177 (350)

232 (450)

WCC Steel

and WC9

Chrome

Moly Steel

1 -29 -20

NPS 1/2 to 1-1/2: 427 (800)

(4)

NPS 2 and 2-1/2: 371 (700)

(4)

NPS 3: 316 (600)

(4)

NPS 4 and 6: 260 (500)

(4)

427 (800)

2

(2)

-29 -20

NPS 1/2 to 1-1/2: 316 (600)

(4)

NPS 2 and 2-1/2: 232 (450)

NPS 3: 204 (400)

NPS 4 and 6: 149 (300)

316 (600)

2A -29 -20

NPS 1/2 to 1-1/2: 343 (650)

(4)

NPS 2 and 2-1/2: 232 (450)

NPS 3: 204 (400)

NPS 4 and 6: 149 (300)

343 (650)

CF8M

(316 SST)

2

(2)

- 254 - 425 316 (600)

(4)

316 (600)

2A - 198

(5)

- 325

(5)

343 (650)

(4)

343 (650)

NPS 8 YD

(WCC)

1 -29 -20 232 (450) 427 (800)

(6)

NPS 8 YD

(CF8M)

2

(2)

- 198 - 325 232 (450) 316 (600)

(6)

2A - 198 - 325 232 (450) 343 (650)

(6)

1. Refer to table 2 for trim materials.

2. Trim 2 limited to 149_C(300_F) maximum for nonlubricating fluids.

3. Cast iron is limited to -73_C (-100_F) minimum

4. Plug cage seals limit this design to 232_C(450_F) maximum.

5. May be used down to -254_C (-425_F) if manufacturing process includes Charpy impact test.

6. Only available in YD constructions.