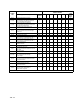

Reference Manual

10B −21

KAMYR

TAG#

KAMYR CONTINUOUS DIGESTER

FISHER CONTROL VALVE

PRODUCT DESIGN

Application Description

Control

Function

V150 V200 V300 V500 CV500 8580

Typical

Valve

Sized

PV-16

No. 1 Flash Steam Pressure

this valve controls pressure in No. 1 Flash Tank

T P 10’’

PV-17

No. Flash Steam Pressure

This valve controls pressure in No. 2 Flash Tank

T P 18’’

PV-30

(1)

Impregnation Vessel Pressure Relief

Relieves excess liquor from Impregnation

Vessel to No. 2 Flash Tank

T P 4’’

TV-2

Chip Bin Temperature

Takes steam from flash tank #2 to provide

steam for atmospheric presteaming in Chip bin

T P 18’’

TV-2A

Chip Bin Temperature

Provides alternate source of steam from low

pressure steam line to Chip Bin

T P 8’’

TV-19H

Modified Cooking Circulation Temperature

Valve controls steam to Modified Cooking

Heater which controls temperature of liquor to

upper wash zone

T P 6’’

TV-20H

Wash Circulation Temperature

Controls low pressure steam to Wash

Circulation Heater of the Digester

T P 6’’

TV-60A

(1)

Bottom Circulation Temperature

Valve controls steam to Bottom Circulation

Heaters which control temperature of liquor

leaving heaters to bottom zone of the

Impregnation Vessel

T P 6’’

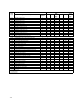

TV-60B

(1)

Bottom Circulation Temperature

Same as TV60A

T P 6’’

TV-60C

(1)

Bottom Circulation Temperature

Same as TV60A

T P 6’’

HV-5

Steaming Vessel Relief

Relief Valve, sends steam to Condenser

T P 6’’

HV-5A

Steaming Vessel Relief Screen Blowback

This valve is used to blow back fresh steam to

clean relief screen

O/O S P 1.5’’

HV-8

(1)

Trim Liquor Downflow

Controls liquor extracted from upper screens

and sends it to bottom Circulation Heater

T P 8’’

HV-16

Digester Extraction to No. 1 Flash Tank

this valve controls extraction flow from

extraction screens KV16A, B, C, D to Flash

Tank #1

T P 8’’

HV-19

Modified Cooking Circulation Flow

Control liquor flow to modified cooking zone

from Modified Cooking Heater

T P 8’’

HV-20

Wash Circulation Flow − Controls wash liquor

from bottom of digester to the Wash Circulation

Heater of the main Digester

T P 4’’

HV-51

(2)

Top Circulation Isolation − Isolation valve for

liquor being sent back to High Pressure Feeder

from Impregnation Vessel. Special male flanges

O/O 14’’

HV-52

(2)

Top Circulation Isolation − this valve isolates

high pressure feeder from the Impregnation

Vessel. Installed on main chip/liquor feedline

O/O 14’’

1. Dual vessel only.

CODE: P = Primary selection, S = Secondary selection, T = Throttling, O/O = On/Off