Instruction Manual

Instruction Manual

D100400X012

EWN and EW-1 Valves

July 2014

11

7. Inspect parts for wear or damage that would prevent proper operation of the valve. Replace or repair trim parts

according to the following Lapping Seating Surfaces or Valve Plug Maintenance procedures as appropriate.

Lapping Seating Surfaces

Seating surfaces of the valve plug and seat ring (keys 2 and 9, figure 7 through 10) can be lapped for improved shutoff.

(Deep nicks should be machined out rather than ground out.) Use a commercial lapping compound or a mixture of

600-grit carborundum and solidified vegetable oil.

Assemble the valve to the extent that the cage or cage assembly is in place and the bonnet bolted to the valve. A

simplehandlecanbemadefromapieceofstrapironlockedtothevalveplugstemwithnuts.Rotatethehandle

alternately in each direction to lap the seats. After lapping, remove the bonnet, and clean the seat surfaces.

Completely assemble the valve as described in the Trim Replacement section, and test the valve for shutoff. Repeat

the lapping procedure if leakage is still excessive.

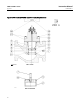

Figure 5. Removal Tool Required for Seat Ring Threaded to Valve Body (also see tables 6 and 7)

FOR136,197,OR203mm(5-3/8,7-3/4,OR8-INCH)SEATRINGS

36A9660-B

B1464

FOR 172 mm (6-3/4 INCH) SEAT RINGS