Technical data

Water/Glycol-Cooled Systems—Capacities and Dimensions

Liebert

®

Mini-Mate2

™

19

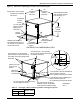

Figure 10 General arrangement diagram water/glycol split systems

Figure 11 General arrangement, free-cooling coil with water/glycol condensing units

*

*

Evaporator

Coil

Tube-in-Tube

Condenser

Tube-in-Tube

Condenser

High-Pressure

Switch

Scroll

Compressor

Hot Gas

Bypass

Solenoid

Valve

Ho

t

G

a

s

B

y

p

a

s

s

Co

n

t

r

o

l

V

a

l

v

e

Liquid Injection

Valve

Suction Line Male Quick

Connect Coupling

Liquid Injection

Valve Bulb

Liquid Line

Male Quick

Connect

Coupling

Water/Glycol

Return Line

Fluid Return

From Unit

Fluid Supply

To Unit

Water/Glycol

Supply Line

Shutoff **

Valves

Hose

Bibs **

2 - Way Water

Regulating Valve

Fluid

Return

From Unit

Fluid Supply

To Un it

3 - Way Water

Regulating Valve

(Optional)

Suction Line Female Quick

Connect Coupling

Liquid Line

Female Quick

Connect

Coupling

Service Access

Ports

Filter

Drier

Expansion

Valve

External

Equalizer

Sensing Bulb

FIELD PIPING

FACTORY PIPING

DPN000214

Rev. 1

* Use Liebert sweat adapter kit with field

hard piping. Close-coupling option available with MCD.

** Components are not supplied by Liebert but are

recommended for proper circuit operation and maintenance.

Fluid

Return

From Unit

Fluid

Return

From

Unit

Fluid

Supply

To U nit

Temperature

Stat

Free-Cooling

Control

Valve

Bleed Valve

Free-Cooling

Coil

Shutoff*

Valves

Shutoff*

Valves

Hose*

Bibs

Hose*

Bibs

Fluid

Supply

To U ni t

3-Way Water

Regulating

Valve

(Optional)

Tube in

Tube

Condenser

DPN000219

Rev. 3

FIELD PIPING

NOTE: RECOMMENDED PIPING FOR UNITS

WITH FREE-COOLING COIL OPTION

AND WATER/GLYCOL CONDENSER.

* Components are not supplied by Emerson

but are recommended for proper circuit

operation and maintenance.

FACTORY PIPING