Specifications

77

The rooftop unit has the design static pressure set point

programmed into the CCN control. This is the maximum set

point that could ever be achieved under any condition. To

simplify the installation and commissioning process for the

field, this system control is designed so that the installer only

needs to enter a maximum duct design pressure or maximum

equipment pressure, whichever is less. There is no longer a

need to calculate the worst case pressure drop at design condi-

tions and then hope that some intermediate condition does

not require a higher supply static pressure to meet the load

conditions. For example, a system design requirement may

be 1.2 in. wg, the equipment may be capable of providing

3.0 in. wg and the supply duct is designed for 5.0 in. wg. In this

case, the installer could enter 3.0 in. wg as the supply static

pressure set point and allow the air terminal system to dynami-

cally adjust the supply duct static pressure set point as required.

The system will determine the actual set point required deliver-

ing the required airflow at every terminal under the current

load conditions. It will always be the lowest value under the

given conditions, and as the conditions and airflow set point at

each terminal change throughout the operating period, and so

will the equipment static pressure set point.

The CCN system must have access to a CCN variable

(SPRESET which is part of the equipment controller). In the

algorithm for static pressure control, the SPRESET value is

always subtracted from the configured static pressure set point

by the equipment controller. The SPRESET variable is always

checked to be a positive value or zero only (negative values are

clamped to zero). The result of the subtraction of the SPRESET

variable from the configured set point is limited so that it

cannot be less than zero.

The result is that the system will dynamically determine

the required duct static pressure based on the actual load

conditions currently in the space. It eliminates the need to

calculate the design supply static pressure set point (although

some may still want to do it anyway). It also saves the energy

that is the difference between the design static pressure set

point and the required static pressure (multiplied by the

airflow). Normally, the VAV system operates at the design

static pressure set point all the time, however, a typical VAV

system operates at design conditions less than 2% of the time.

A significant saving in fan horsepower can be achieved utiliz-

ing static pressure reset.

Building Pressure Control — The control will sup-

port control of the building pressure using power exhaust fans.

The type of control is configured using the PWRX variable.

The types are as follows:

PWRX = 0, No building pressure control

PWRX = 1, Building pressure control based on economizer

position

PWRX = 2, Modulating building pressure control based on

building pressure sensor

When PWRX is 1 or 2, there are either four or six power ex-

haust motors, attached to three relays. See Table 39.

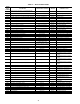

Table 39 — Power Exhaust Fan Relays

For a PWRX configuration of 1 the control will use the con-

figurable PE Stage 1 Econo Position (PE1.P) and PE Stage 2

Econo Position (PE2.P) damper positions to operate two stages

of power exhaust. For a 4-motor system the first stage of

exhaust will energize PE-B and the second stage will energize

all PE relays.

For a PWRX of 2 the control will use a building pressure

sensor to control the sequencing of the power exhaust fans. A

PID control loop will be used. This can be used on both VAV

and CV units. The fan stages as shown in Table 40 will be used

to control the measure building pressure to the configurable

Building Pressure Set Point (BP.SP).

The control has 3 modes of running the fans for building

pressure control mode. Option 2 should be used.

Table 40 — Modulating Power Exhaust

Staging Sequence

SIZES 020-050

SIZE060

BUILDING PRESSURE SET POINT (BP.SP) — This is the

building pressure set point. It is located in the SETPOINT-

BP.SP submenu.

POWER EXHAUST TYPE (PWRX) — This is the type of

power exhaust and has the following options. It is located in the

CONFIGURATION-ECON submenu.

• MODULATING — This will use the building pressure

sensor.

• 2 STAGE — This will control the dampers based on the two

configurable damper position set point.

• NONE — No building pressure control will be used. This

should be set to NONE for barometric relief dampers.

POWER EXHAUST MOTORS (PWRM) — This configures

the number of power exhaust fan motors and has the following

options.

• 4 MOTORS — This should be used on all units except size

060.

• 6 MOTORS — This should be used on size 060 units.

PE STAGE 1 ECONO POSITION (PE1.P) — This is the

damper position that will be used to turn on the first stage of

fans when using 2 stage control.

PE STAGE 2 ECONO POSITION (PE2.P) — This is the

damper position that will be used to turn on the second stage of

fans when using 2 stage control.

MODULATING PE ALG SELECT (BP.SL) — This is a selec-

tion for different power exhaust control routines. Only routine

2 should be used.

BUILDING PRESSURE SENSOR (BP.S) — This is used to

enable and disable the use of a building pressure sensor. It must

be enabled for the modulating control to work. It can also be

enable for the other modes where monitoring of the building

pressure is desired.

UNIT

SIZE

SETTING

PE_A

RELAY

PE_B

RELAY

PE_C

RELAY

020-050

PWRM = 1

(4 motors)

1 Motor 2 Motors 1 Motor

060

PWRM = 2

(6 motors)

1 Motor 2 Motors 3 Motors

PWRM = 4PE_APE_BPE_C

Stage 0 OFF OFF OFF

Stage 1 ON OFF OFF

Stage 2 OFF ON OFF

Stage 3 ON ON OFF

Stage 4 ON ON ON

PWRM = 6PE_APE_BPE_C

Stage 0 OFF OFF OFF

Stage 1 ON OFF OFF

Stage 2 OFF ON OFF

Stage 3 ON ON OFF

Stage 4 ON OFF ON

Stage 5 OFF ON ON

Stage 6 ON ON ON