Specifications

76

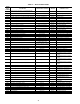

Table 38 — VFD (E3 Inverter) Configurations

*These settings differ from the Toshiba defaults and are required for Carrier applications.

DIFF. GAIN SF VFD (SP.KD) — This is the differential gain

for the static pressure control PID control loop.

INTEGRAL GAIN SF VFD (SP.KI) — This is the integral

gain for the static pressure PID control loop.

SYSTEM /GAIN SF VFD (SP.K) — This is the overall sys-

tem gain for the static pressure PID control loop.

VFD PID TIME (SECONDS) (SP.DT) — This is the time

factor for the static pressure control PID loop.

DUCT PRESS SENSOR HI END (SPHL) — This is the

maximum static pressure that the sensor will measure when the

signal is 20 mA.

DUCT PRESS SENSOR LO END (SPLL) — This is the

minimum static pressure that the sensor will measure when the

signal is 4 mA.

Under most operating conditions the control PID factors

will not require any adjustment and the factory defaults should

be used. If a condition is detected where the VFD speed is

fluctuating up and down from the static pressure and it over-

shoots and undershoots the set point, then use the System Gain

SF VFD (SP.K) factor. Decrease the factor a small amount to

reduce the responsiveness of the control loop and increase it to

increase the responsiveness of the control loop. Do not change

the other factors without consulting with Carrier Application

department.

Static Pressure Reset — The ComfortLink™ con-

trols supports the use of static pressure reset. For static pressure

reset to occur, the unit must be part of a CCN system with

access to CCN reset variable and the Linkage Master Terminal

System Logic.

The Linkage Master terminal monitors the primary air

damper position of all the terminals in the system (done

through LINKAGE with the new ComfortID™ air terminals).

It then calculates the amount of supply static pressure reduction

necessary to cause the most open damper in the system to open

more than the minimum value (60%) but not more than the

maximum value (90% or negligible static pressure drop). This

is a dynamic calculation, which occurs every two minutes

whenever the system is operating. The calculation ensures that

the supply static pressure is always enough to supply the

required airflow at the worst case terminal but never more than

necessary, so that the primary air dampers do not have to oper-

ate with an excessive pressure drop (more than required to

maintain the airflow set point of each individual terminal in the

system). As the system operates, if the most open damper

opens more than 90%, the system recalculates the pressure

reduction variable and the value is reduced. Because the reset

value is subtracted from the controlling set point at the equip-

ment, the pressure set point increases and the primary air

dampers close a little (to less than 90%). If the most open

damper closes to less than 60%, the system recalculates the

pressure reduction variable and the value is increased. This

results in a decrease in the controlling set point at the equip-

ment, which causes the primary air dampers to open a little

more (to greater than 60%).

SetP SETUP PARAMETERS GR.SF FREQ. SETTING PARAMETERS

ACC1 60.0 sec Fsor 60 Hz

DEC1 60.0 sec Gr.Pn PANEL CONTROL PARAMETERS

UL 60.0 Hz Fr 0*

LL 0 Hz FGr.St TERMINAL SELECTION PARAMETERS

lulu 1 lt 1

P3 20% lt0 0

F-P3 0.0 Hz lt1 56

P4 100% lt2 13

F-P4 60 Hz lt3 3

tHr1 — lt4 10

StC1 0 GGr.Pr PROTECTION PARAMETERS

StL1 110% UuC 1*

OLN 1 UuCt 2

tYP 5 ArSt 3

Gr.F FUNDAMENTAL PARAMETERS Gr.Ut UTILITY PARAMETERS

FH 60Hz* Cnod 4*

UL 60Hz Fnod 4*

pt 2 bLPn 1*

GR.Fb FEEDBACK PARAMETERS

FbP1 0*

Fbln 2

GP 0.3

Gl 2 sec

GA 0

GFS 0 80

P1LL 10

PuL 1

PuU1 10

PuLL 10