Specifications

75

Pre-Occupancy Purge — The control has the option

for a pre-occupancy purge to clear the space prior to occupan-

cy. The feature is enabled by the PRG.E variable which is locat-

ed in the CONFIGURATION-IAQ submenu.

The IAQ Purge will operate under the following conditions:

• PRG.E is enabled

• the unit is in the unoccupied state

• Current Time is valid

• Next Occupied Time is valid

• time is within two hours of the next occupied period

• time is within the purge duration

If all of the above conditions are met, the following logic is

used:

If (OAT >= NTLO and OAT <= OCSP and economizer is

available)

Then PURGEMP = 100%

Else if (OAT < NTLO)

Then PURGEMP = LT.MP (default = 10%)

Else PURGEMP = HT.MP (default = 35%)

If PURGEMP > 0% then IAQ Purge Mode is enabled.

If this mode is enabled the indoor fan and heat interlock re-

lay (VAV) will be energized and the economizer's minimum

position is set to PURGEMP.

PURGEMP = 0% when IAQ purge mode is not active (en-

abled).

The following configurations are used for this option.

IAQ PURGE (PRG.E) — This is used to enable IAQ

pre-occupancy purge. This can be configured in the

CONFIGURATION-IAQ submenu.

IAQ PURGE LO TEMP MIN POS (PG.LT) — This is used

to configure a low limit for damper position to be used

during the purge mode This can be configured in the

CONFIGURATION-IAQ submenu.

IAQ PURGE HI TEMP MIN POS (PG.HT) — This is used

to configure a maximum position for the dampers to be

used during the purge cycle. This can be configured in the

CONFIGURATION-IAQ submenu.

NIGHT TIME LOCKOUT TEMP (NT.LO) — Night time

lockout temperature below which the purge cycle will be dis-

abled. This is configured in the SETPOINTS-COOL submenu.

Static Pressure Control — The control supports the

use of an VFD for fan speed control and static pressure control.

All VAV units are equipped with an VFD for the supply fan.

The speed of the fan will be controlled directly by the

ComfortLink™ Control. A duct static pressure sensor is locat-

ed in the auxiliary control box The signal from the pressure

sensor will be measure by the ECB2 board and will be used in

a PID control routine in the ComfortLink Controls that will

output a 4 to 20 mA signal to the VFD. The static pressure con-

trol set point (SP.SP) is in the SETPOINTS-SP.SP submenu.

Other configurable variables that apply to static pressure con-

trol are listed below. These can be set in the CONFIGURA-

TION-SVFD submenu.

The VFD also has configuration settings which are set at the

VFD. These settings are shown in Tables 37 and 38.

The supply fan relay is not turned off when controlling a

VFD. This is to prevent condensation on the VFD and associat-

ed electronics. The speed will be set to 0% when the unit is in

the Off Mode.

DUCT STATIC PRESSURE SENSOR (SP.S) — This en-

ables the use of a supply duct static pressure sensor. This must

be enabled to use the ComfortLink control loop. If using a

third party control for the VFD then this should be disabled.

STATIC PRESSURE CONTROL (SP.C) — This is used to

configure the use of the ComfortLink for VFD control. It has

the following options:

• NONE — No direct VFD control by ComfortLink control.

This would be used if there was third-party control of the

VFD. The control of the VFD must be provided.

• VFD CONTROL — This will enable the use of the

ComfortLink VFD and static pressure control.

IDF VFD MINIMUM SPEED (SF.MN) — This is the mini-

mum speed that the VFD will turn down to. The inverter also

has a minimum speed adjustment.

IDF VFD MAXIMUM SPEED (SF.MX) — This is the max-

imum speed that the VFD can ramp up to. Usually this is set to

100%.

IDF SPEED IN FIRE MODE (SF.FS) — This is the speed

that the VFD will use during the fire modes like pressurization,

and purge.

PROP. GAIN SF VFD (SP.KP) — This is the proportional

gain for the static pressure control PID control logic.

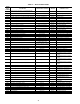

Table 37 — VFD (S9 Inverter) Configurations

TITLE

COMMUNICATION

NUMBER

FUNCTION

DEFAULT

SETTING

CARRIER

SETTINGS

COMMENTS

CMOD 0003 Command Mode Selection 1 0 Auto Operation

FMOD 0004 Frequency Setting Mode Selection 2 0 Remote Operation

Fr 0008 Forward/Reverse Run Selection 0 1 Reverse run (required due to fan config)

ACC 0009 Acceleration Time 1 10 60

DEC 0010 Deceleration Time 1 10 60

FH 0011 Maximum Frequency 80 60

UL 0012 Upper Limit Frequency 80 60

Pt 0015 V/F Control Mode Selection 0 1 Variable torque load

F116 0116 Input Terminal Selection (S3) 8 11 Normally open E-Stop

F201 0201 VIA/II Input 1 Setting 0 20 0 Hz at 4 mA

F204 0204 V1A/II Input 2 Frequency 80 60 60 Hz at 20 mA

F300 0300 PWM Carrier Frequency 12 4

F301 0301 Auto-Restart Control Selection 0 3 Auto -restart activated

F302 0302

Regenerative Power Ride

through Control

01

Enable ride though

F303 0303 Retry Selection 0 2 Number of retrys

Sr1 0018 Pre-Set Speed 1 0 60 Fire Speed

OLN 0017 Electronic Thermal Protection 1 1=overload and stall protection