Operating Instructions and Installation Instructions

ULTRAMAX PB 65 - 120

6 L290 ©MHS Boilers 13/12/2010

The following Codes of Practice are also applicable: -

BS 5449:1990 Specification for forced circulation hot water central heating systems for domestic premises.

BS 6644:2005 Specification for gas fired hot water boilers of rated inputs between 70kW (net) and

1.8MW(net) (2

nd

and 3

rd

family gases).

BS 6880:1988 Code of Practice for low temperature hot water heating systems of output greater than 45kW.

Parts 1,2 & 3.

BS 6891:1988 Specification for installation of low-pressure gas pipework of up to 28mm (R1) in domestic

premises (2

nd

family gases).

BS 7593:2006 Code of Practice for treatment of water in domestic hot water central heating systems.

BS 7671:1992 Requirements for electrical installations. IEE Wiring Regulations. Seventeenth Edition

CISBE Guide reference sections B7, B11 and B13.

CP342 Part 2: 1974 Code of Practice for centralized hot water supply.

IGE/UP/1 or 1A Gas Tightness Testing & Purging of Commercial Industrial Gas Installations

IGE/UP/2 Gas installation pipework, boosters and compressors on Industrial and Commercial premises.

IGE/UP/4 Commissioning of gas fired plant on industrial and commercial premises.

IG/UP/10 edition 3 Installation of gas appliances in Industrial and Commercial premises.

Part 1: Flued appliances.

1.3 Hot Water Quality

Composition and quality of the system water directly affects the performance of the entire system and the

longevity of the boiler.

For the initial filling and subsequent refilling of the system, under normal circumstances, regular tap water with

a pH value between 7 and 8 can be used unless the water is highly corrosive (chloride content > 150 mg/l) or

very hard (<14° dH, hardness level IV). A tap water analysis can be requested from the local water utility

company. If the specific system volume is greater than 20 litre/kW of heating power (for example through

installation of a heating water buffer reservoir) the maximum permissible introduction of calcium via fill and

replacement water must be determined according to the calculations specified in VDI Guidelines 2035.

Softening of the fill water may have to be performed if necessary.

1.4 Unknown Water Quality and Exchanger Systems

Quite frequently, water contains materials and additives, which affect function and longevity of the Heat

exchanger. Therefore, either

Prior to exchanging the equipment, heat up the old system and drain completely afterwards.

OR

After exchanging the equipment, rinse the heating system carefully.

1.5 Existing System

For old systems, floor heating systems and problematic system water, MHS Boilers recommends the

installation of a plate heat exchanger to segregate the primary and secondary systems.

1.6 Scope of Delivery

Ultramax PB condensing boiler with switch panel, including exterior sensor with weather-regulated

heating control for 1 heating circuit and hot water conditioning

Documentation.

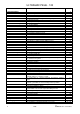

Criterion

Permissible

Value

Effect upon Deviation

pH

7-8

Risk of corrosion for boiler components and heating system

Hardness

<14 dH

- increased calcium deposits

- reduced longevity of boiler

Chloride

content

<150 mg/l

Corrosion of alloy materials