Operating Instructions and Installation Instructions

ULTRAMAX PB 65 - 120

43 L290 ©MHS Boilers 13/12/2010

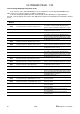

18.0 Information Display

18.1 Via AGU 2.311 Operating Panel

Parameters of Groups b, c and d are provided upon request only.

Display Level

LMU Functional ID

Description

Temperatures (specialist level)

b 0

Diagnose Code

LMU internal SW diagnostics code

b 1

TkRuec

Boiler return temperature

b 2

Tbwist2

Reservoir temperature at sensor 2 (non existent)

b 3

Tabgas

Exhaust temperature

b 4

TiAussen

Exterior temperature

b 5

TaGem

Mixed exterior temperature

b 6

TaGed

Dampened exterior temperature

b 7

Tvist

Flow temperature AGU 2.500

b 8

Not assigned

b 9

Not assigned

Process values (specialist level)

c 0

Not assigned

c 1

IonStrom

Ionisation flow

c 2

Gebl_Drehz

Blower rpb

c 3

Gebl_PWM_AusAkt

Current blower control (PWM)

c 4

RelModLevel

Relative output

c 5

Pump_PWM

Pump target value (PWM)

c 6

Ek0

Control difference

c 7

Not assigned

c 8

Not assigned

c 9

Not assigned

Target values (specialist level)

d 0

Not assigned

d 1

Tsoll

Target value for 2-point and modulating control valve (PID)

d 2

TkSoll

Current boiler target value

d 3

RsRaum

Room temperature target value

d 4

TbwSoll

Reservoir target value

d 5

PhezMax

Maximum degree of modulation during heating mode

d 6

NhzMax

Maximum rpm at maximum output during heating mode.

d 7

Not assigned

d 8

Not assigned

d 9

Not assigned

Note: By either pushing the “mode” button or waiting for 8 minutes, the display automatically reverts back to

the standard display.

1. Push information button. 2 Push buttons

for at least 3 seconds until b0 appears in the display.

3 Push button

then alter b0 to c0 4 Push buttons to select the respective parameter.

1. Push information button. 2 Push buttons

for at least 3 seconds until b0 appears in the display.

3 Push 2 x button

then alter b0 to d0 4 Push buttons to select the respective parameter.