Operating Instructions and Installation Instructions

ULTRAMAX PB 65 - 120

3 L290 ©MHS Boilers 13/12/2010

7.0 Gas connection

24

8.0 Mounting the exterior

temperature sensor

25

9.0 Electrical Installation

25

9.1 General Notes

25

9.2 Dimensioning of power connection wiring

26

9.3 Power connection and connection of customer- provided

wiring.

26

9.4 Terminal layout

27

10.0 Commissioning

28

10.1 Re-circulation Pump

29

10.2 Control Measures

29

10.3 Minimum circulation amounts / Flow monitoring

29

10.4 Ensure prior to commissioning

29

10.5 Description of Control Valve Stop Function.

30

10.6 Trigger.

30

10.7 Function.

30

10.8 Settings

30

10.9 Adjustment of combustion quality

31

10.10 Adjustment values for Natural Gas.

31

10.11 Conversion from Natural Gas to LPG.

31

10.12 Adjustment values for liquid gas.

31

10.13 Switch Panel and AGU Operating Panel

32

10.14 AGU Operating Panel

33

10.15 AGU Operating Panel (continued)

34

10.16 Information Button

34

10.17 Adjustment of Target Temperature for Heating Circuit

35

10.18 Adjustment of Target Temperature for Domestic Hot

Water “DHWTarget”

35

11.0 Parameterisation (End

User)

36

11.1 Adjustment for individual End User Requirements

36

11.2 Parameterisation for End User

37

12.0 Clock Function

38

12.1 Effect

38

12.2 Description of Domestic Use Water Provision

38

12.3 Operating Mode

38

12.4 Effect

38

13.0 Function upon

Attached Room Device

QAA73 (Accessory)

38

14.0 Backlight

39

15.0 Maintenance and

Service

39

16.0 Cleaning

40

16.1 Disassembly of the Burner

40

16.2 Cleaning the Burner and Fan

40

16.3 Cleaning the Heat Exchanger

41

17.0 Error Message List

42

17.1 Error Messages Displayed via AGU Operating Panel

42

18.0 Information Display

43

18.1 Via AGU 2.311 Operating Panel

43

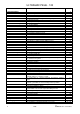

19.0 Level One Parameters

Review and Alternation

44

20.0 Reviewing LMU64

Operating Error Codes

45

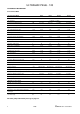

22.0 Full Parameters List

46 - 54

Appendix A

Supplementary information on the AUG 2.511 communication

clip-in module.

55