OPERATOR’S MANUAL ENGINE CUT-OFF SAW CSG-7410 WARNING The engine exhaust from this product contains chemicals known to the State of California to cause cancer, birth defects or other reproductive harm. Cancer and Reproductive Harm www.P65Warnings.ca.gov WARNING Read the instructions carefully and follow the rules for safe operation. Failure to do so could result in serious injury.

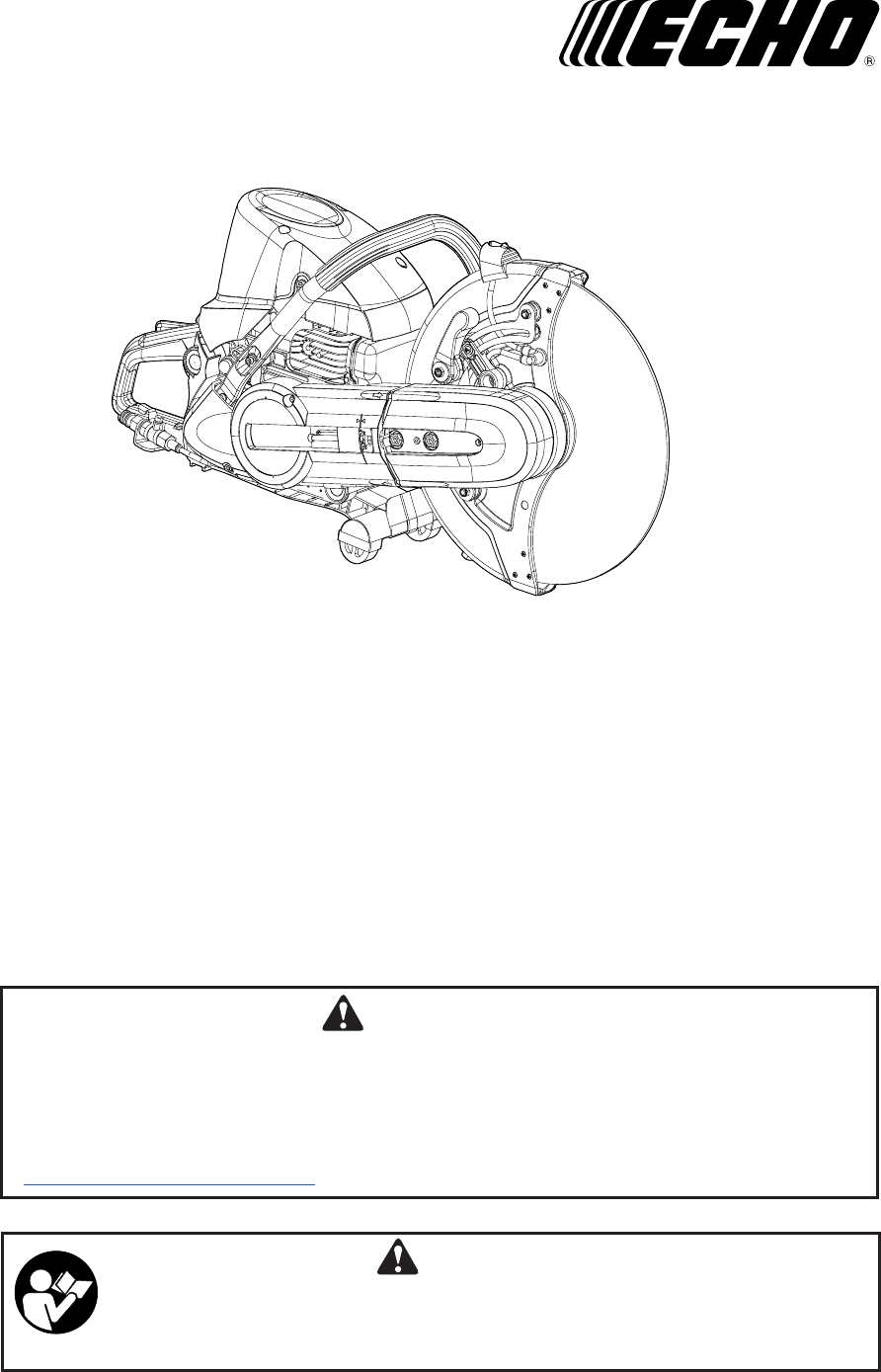

INTRODUCTION The ECHO model CSG-7410 Engine Cut-off saw is a high-performance gasoline-powered tool designed for use with a recommended 350 x 4.7 x 20 mm (14 in. x 6/32 in. x 25/32 in.) abrasive wheel. A water-flush attachment is available for dust control. Use only ECHO’s wheels or other wheels having a minimum spindle speed rating of 3820 rpm or higher. This manual provides the information necessary for assembly, operation and maintenance of the cutoff saw as well as the wheels available for it.

SYMBOLS AND SIGNS DANGER CIRCLE AND SLASH SYMBOL The safety alert symbol accompanied by the word “DANGER” calls attention to an act or condition which WILL lead to serious personal injury or death if not avoided. This symbol means the specific action shown is prohibited. Ignoring these prohibitions can result in serious or fatal injury.

SYMBOL FORM Symbol form/shape Symbol description/application Symbol form/shape Symbol description/application WARNING!! Choke control Read and follow all safety precaution in the Operator's Manual. Failure to follow instructions could result in serious personal injury. Always wear an ear muffler, Oil and gasoline mixture a dust proof mask, goggles and a helmet when operating this machine. (ANSI Z87.1) Do not run the engine indoors, or where there is poor ventilation.

PACKING LIST The ECHO product you purchased has been factory pre-assembled for your convenience. Due to packaging restrictions, wheel installation and other assembly may be necessary. After opening the carton, check for damage. Immediately notify your retailer or ECHO dealer of damaged or missing parts. Use the packing list to check for missing parts. ECHO engine cut-off saw 13 x 19 mm T-wrench Bar tool Operator's manual Warranty sheet Adapter (25.

NOMENCLATURE OF PARTS 3 23 2 23 23 13 4 12 5 11 10 6 23 8 7 9 23 22 21 20 19 14 15 16 1 17 18 OPERATOR’S MANUAL ENGINE CUT-OFF SAW CSG-7410 WARNING Read the instructions carefully and follow the rules for safe operation. Failure to do so could result in serious injury.

NOMENCLATURE OF PARTS 1. Operator's manual - Included with unit. Read before operation and keep for future reference to learn proper, safe operating techniques. 12. Starter grip - Pull handle slowly until starter engages then quickly and firmly. When engine starts, return handle slowly. Do not let handle snap back or damage to unit will occur. 2. Front handle (for the left hand) - Support handle located at the front of the engine housing. 13. Air cleaner cover - Covers air cleaner. 14.

OPERATOR SAFETY PRECAUTIONS Read this engine cut-off saw operator’s manual carefully. Be sure you understand how to operate this saw properly before you use it. Establish a training program for engine cut-off saw operators. OPERATOR’S MANUAL ENGINE CUT-OFF SAW CSG-7410 WARNING Read the instructions carefully and follow the rules for safe operation. Failure to do so could result in serious injury. Use safety footwear, snug-fitting clothing and protective gloves.

Keep a firm grip on the engine cut-off saw with both hands, the right hand on the rear handle, and the left hand on the front handle when the engine is running. Use a firm grip with thumbs and fingers encircling the saw handles. A firm grip will help you to keep control if the saw kickback toward you, or the thrust of the rotating wheel pulls it away from you. Never operate the engine cut-off saw with only one hand. Be careful around electrical cables, sewer and gas lines to avoid cutting them.

OPERATOR SAFETY Protective Equipment You must wear eye protection goggles qualified to the CE mark or the latest ANSI Standard Z 87. (Z 87 is stamped on the goggles). These goggles also must be worn under a face screen if one is used. A face screen should be worn when there is a risk from flying debris. WARNING Engine cut-off saw users risk injury if the saw is used improperly, and / or safety precautions are not followed.

Physical Condition Your judgment and / or dexterity may be impaired if you are ill or have taken alcohol or other substances known to affect the way you would function normally. Operate only when sound in mind and body. WARNING Precautions Against Vibration and Cold It is believed that a condition called Raynaud’s Phenomenon which affects the fingers of certain individuals is brought about by exposure to cold and vibration.

ABRASIVE WHEEL TYPES AND USES ECHO Reinforced Wheels ECHO Wheels are labelled for the type of materials they are designed to cut. The types of wheels identified below, and other types, may be available from ECHO dealer. WARNING This saw includes an abrasive wheel and a water system. Do not use water with an abrasive wheel. Labeled Application Primary Use Other Uses Dry or Water Flush Metal General purpose mild and stainless steel: re-bar, pipe and structural steel Aluminum and soft brass.

Wheel Blotters and Mounting Flanges Blotter 108 mm Wheel blotters attached to both sides of reinforced wheels are cushions needed to equalize the pressure of the mounting flanges from wear if slippage between the wheel and the flanges occurs. The blotters are 108 mm (4 1/4 in.) diameter. Take care that the blotters do not become gouged or deeply scratched and that there is no foreign material on them when mounting the wheel. 20 mm (25.

Facts About Abrasive Wheel ECHO wheels are made by laying a strong fibre mesh material into a form, pouring a mixture of resin and the abrasive grit particles over the mesh, and adding a second layer of mesh over the mixture. Then the resin and reinforcing mesh are bonded together and cured. The wheel’s ability to cut certain materials are due to the type abrasive, size of the grit and it’s spacing. The reinforcement on both sides adds strength and rigidity. Always read the label on the wheel.

PREPARATION FOR USE How to Install the Wheel Replacing the Adapter Install the adapter that fits the inside diameter of the cutting wheel. When shipped, an adapter with an outside diameter of 20 mm is mounted. If the inside diameter of the cutting wheel to be used is 25.4 mm, replace the adapter as follows. 1. Insert the bar tool. 2. Rotate the drive shaft until the hole in the large pulley and the bar tool aligned. Bar Tool 3.

WARNING Before tightening, check that flanges are properly seated and not cocked on the mount or bolt threads. Do not make bolt so tight as to destroy the cushion supplied by the wheel blotters. Do not use pneumatic, electric-powered tools or one’s body weight for tightening. Otherwise the thread could be broken. Do not tighten more than 30 N•m (300 kgf•cm). NOTE Arm may be removed and remounted with wheel on the outboard side of the arm as required for certain procedures.

7. Loosen the nut of the locking knob and reinstall it after changing the angle of the knob. Locking Knob 8. Change the angle of the wheel guard. Pulley cover 9. Loosen the tension screw until its tip cannot be seen, then remove the 2 pulley cover bolts. 10. Remove the pulley cover. Tension screw Belt 11. Remove the cutter arm from the crankcase. Remove the belt at the same time. 12. Reverse the cutter arm and mount it in the long hole in the crankcase. 13. Put the belt on the pulley.

FUEL FUEL AND LUBRICANT NOTICE ECHO brand 2-stroke oils may be mixed at 50:1 ratio for application in all ECHO engines sold in the past regardless of ratio specified in those manuals. WARNING Diesel fuels and alternative fuels, such as E-15 (15% ethanol), E -85 (85% ethanol) or any fuels not meeting ECHO requirements are NOT approved for use in ECHO 2-stroke gasoline engines.

EMISSION DATA Mixing Instructions 1. 2. 3. 4. Fill an approved fuel container with half of the required amount of gasoline. Add the proper amount of 2-stroke oil to gasoline. Close container and shake to mix oil with gasoline. Add remaining gasoline, close fuel container, and remix. Gas gal. 1 2 5 Fuel to Oil Mix – 50:1 Ratio US Metric Oil Gas fl.oz. L 2.6 5 5.2 10 13 25 EMISSION CONTROL (EXHAUST and EVAPORATIVE) EPA 2010 and Later and/or C.A.R.B.

OPERATION Safe Starting Techniques Set saw down on level ground with wheel in the clear. Grasp front handle with left hand, and hold down rear handle with toe of your boot. Never “dropstart” the saw. WARNING Wheel will rotate when engine is started at fast idle throttle latch setting. Keep cutting wheel in the clear. IMPORTANT Check unit for loose nuts, bolts and screws before starting. Make sure the wheel guard is securely in place. Always clear work area of debris before starting operation.

WHEN THE ENGINE IS WARM Starter grip 1. Fill the fuel tank with fuel mixture. It is not permitted to fill fuel above the shoulder level of fuel tank. 2. Press the decompression device. 3. Securely hold the engine cut-off saw. Pull starter grip briskly, but only 1/2 to 2/3 its full length. Pulling rope to the end may damage the starter.

CUTTING INSTRUCTION Sequence after Starting Engine 1. Squeeze and release trigger to unlatch it and take control of the throttle. 2. Let engine warm to operating temperature before doing any cutting. 3. Take cutting stance on left side of saw. Never get any part of your body behind the saw. Hold the saw firmly with both hands. Throttle up to cutting speed and make gentle wheel contact with the work.

Cutting Technique The main objectives are to avoid overheating the wheel, and to prevent it from being pinched or trapped or stressed in any way. Adjust position of wheel guard to direct the discharge away from you. Prepare to make straight cuts only. Use a snapline to mark long cuts, and follow the marked line carefully. Take a balanced, comfortable stance on the left side of the saw. Hold saw firmly with both hands. Always throttle up to cutting speed before letting the wheel make contact.

MAINTENANCE AND CARE SKILL LEVELS Your ECHO engine cut-off saw is designed to provide many hours of trouble free service. Regular scheduled maintenance will help your engine cutoff saw achieve that goal. If you are unsure or are not equipped with the necessary tools, you may want to take your unit to an ECHO Service Dealer for maintenance. To help you decide whether you want to DO-IT-YOURSELF or have the ECHO Dealer do it, each maintenance task has been graded.

Air Filter The air filters of this product are designed to be maintenance-free for a long period of time. However, in the following cases the main and sub air filters should be replaced. ・If engine output drops markedly ・After 1 year or 50 hours of operation IMPORTANT Do not attempt to clean the main or sub air filters with compressed air. Bolts (A) Air Cleaner Cover Air Filter Replacement Procedure Grommets 1. Remove the 4 grommets on the air cleaner cover. 2.

Spark Plug Spark plug lead 1. Remove air cleaner cover. 2. Remove spark plug lead. 3. Remove spark plug. 4. The proper spark plug for this engine is NGK BPMR7A. The firing gap between the electrodes should be adjusted to 0.65 mm (0.026 in) before use. Spark plug 5. Install the spark plug. Proper tightness with a cold engine is 17 to 19 N•m (170 to 190 kgf•cm). 6.

Carburetor Adjustment Every unit is run at the factory and the carburetor is set in compliance with Emission Regulations. In addition, the carburetor is equipped with “H” (High Speed) and “L” (Low Speed) needle adjustment limiters that prevent settings outside acceptable limits. Idle adjusting screw High speed needle (H) 1. Before adjusting carburetor clean or replace air filter and muffler “Spark Arrestor Screen”. 2. Install the wheel. 3.

Cylinder Fins Cylinder fins 1. Check periodically. 2. Clogged fins will result in poor engine cooling. 3. Remove dirt and dust from between fins to let cooling air pass easily. Muffler Spark Arrestor 1. Remove air cleaner cover and remove spark plug lead. Spark arrestor screen 2. Remove the cutter arm. (See page 30.) 3. Remove spark arrestor screen cover and screen from muffler body. 4. Clean carbon deposits from muffler components. Bolts 5. Replace screen if it is cracked, or has holes burned through.

Belt Change and Adjustment Adjusting the Belt Adjust the belt if it becomes loose. Mark Washer 1. Loosen the 2 pulley cover bolts about 1 turn. 2. Turn the tension screw so the washer lines up with the mark on the clutch cover. 3. Tighten the 2 pulley cover bolts. Note: Tighten to a torque of 23 to 27N・m (230 to 270 kgf・cm). Bolt Tension screw Replacing the Belt Replace the belt when it becomes very worn (peeling, turning, cuts, cracking, etc.) Water-flush pipe Tension screw Pipe connector 1.

8. Fit the cutter arm into the long hole in the crankcase and then put the belt on the large pulley. Cutter arm Belt 9. Put the pulley cover on along the outside of the cutter arm. Make sure the pulley cover is not misaligned when putting it into the arm. Large pulley 10. Tighten the 2 pulley cover bolts and then back them off 1 turn. Adjust the tightness of the belt. 11. Tighten the 2 pulley cover bolts. Note: Tighten to a torque of 23 to 27N・m (230 to 270 kgf・cm). 12.

Troubleshooting Cutting Problems Trouble Probable Cause Bearing down too hard Binding in crooked cut Binding in closing cut Loose belt Remedy Wheel stops when cutting pressure is applied 1. 2. 3. 4. 1. 2. 3. 4. Ease up cutting pressure Lay out and follow a straight line Support material so cut will open Increase belt tension Wheel stops when cutting pressure is applied Belt worn beyond the limit Replace belt Poor cutting – wheel discolored at outer area Heat damage Replace wheel.

STORAGE AFTER USE WARNING WARNING Momentary stop switch automatically returns to run position. Engine can start unintentionally when starter handle is pulled. Always remove spark plug lead from spark plug before pulling starter handle, otherwise severe personal injury may result. Do not store in an enclosure where fuel fumes may accumlate or reach an open flame or spark. CAUTION Do not lend or rent your engine cut-off saw without the Operator's Manual.

TECHNICAL DATA CSG-7410 Model External dimensions : Without cutting wheel Length × Width × Height mm (in) Mass : Without cutting wheel and empty tank kg (lb) 620 × 240 × 407 (24.4 x 9.4 x 16.0) 10.7 (23.6) Volume : Fuel tank mL 700 (23.67) (US fl. oz.) Fuel ( Mixture ratio ) 50:1 ratio with ECHO band oil, ISO-L-EGD (ISO/CD 13738), JASO M345-FC/FD two-stroke, air-cooled engine oil. Use 89 octane unleaded. Do not use fuel containing methyl alcohol, more than 10% ethyl alcohol or 15% MTBE.

WARRANTY REGISTRATION SHEET Thank you for choosing ECHO Power Equipment Please go to http://www.echo-usa.com/Warranty/Register-Your-ECHO to register your new product on-line. It’s FAST and EASY! NOTE: your information will never be sold or misused by ECHO, Inc. Registering your purchase enables us to contact you in the unlikely event of a service update or product recall, and verifies your ownership for warranty consideration.

NOTES 35 CSG-7410

C72715001001 – C72715999999