Operating instructions

8. Making the Machine Operational and Conducting a

Sewing Test

–

Clean the machine after delivery.

–

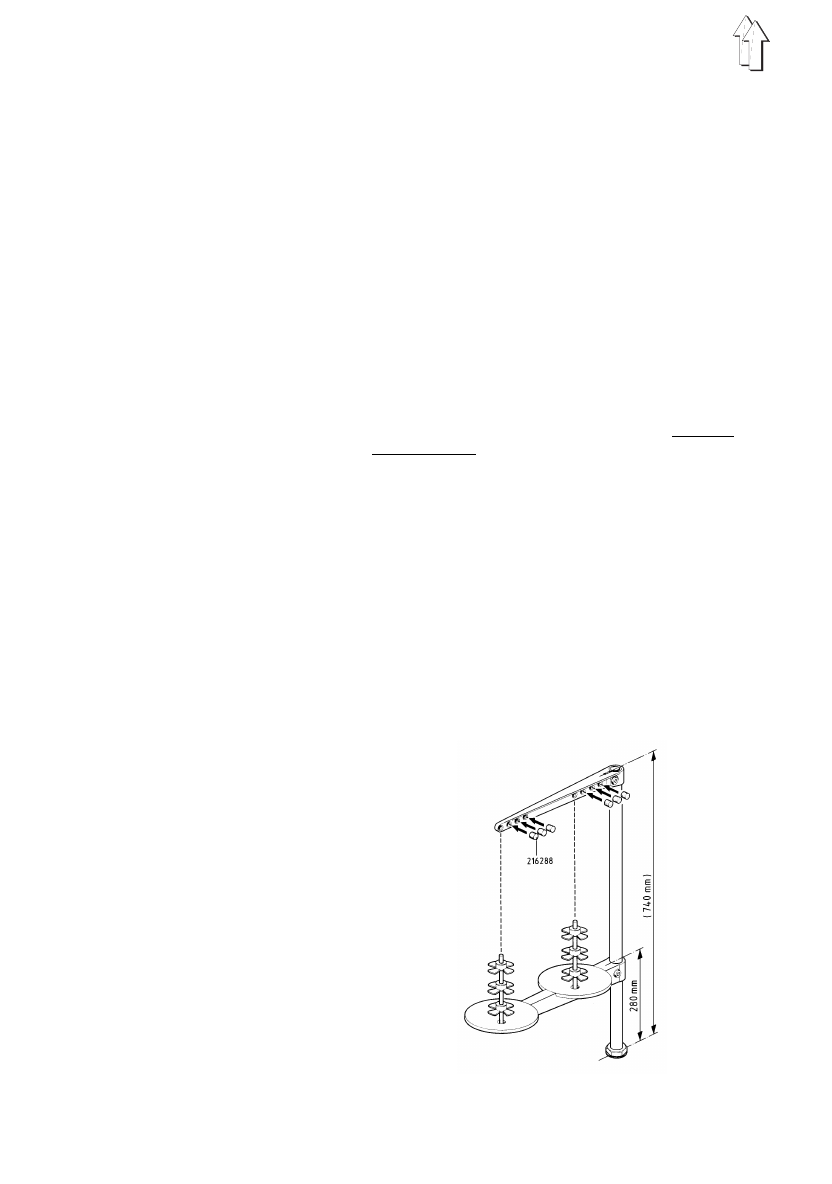

Attach the thread stand as per the following sketch.

–

As shown, close the thread holes with the enclosed

plugs.

–

Needle and bobbin thread may only be threaded

through one thread hole each.

–

Fill the oil reservoir for hook lubrication and central

oil wick lubrication up to the "Max" mark with oil. See

Section 4 of the operating instructions.

–

It is essential to use ESSO SP-NK 10 or an oil of

absolutely comparable quality for lubrication.

–

Insert the mains plug. By switching on the motor

protection switchs for a short period on

3-phase

sewing drives establish the direction of rotation at

the ventilator wheel of the motor.

–

Machine direction of rotation see arrow on the belt

guard.

–

by incorrect direction of rotation exchange 2 phases

on the mains plug.

–

Allow the machine to run for a few minutes at low

rpm before sewing with the highest allowable rpm.

–

Check the pumping quantity of the oil mister (approx.

1 drop per 15 work cycles ) and correct, if necessary.

See Section 4 of the operating instructions.

13