Instruction Manual

19

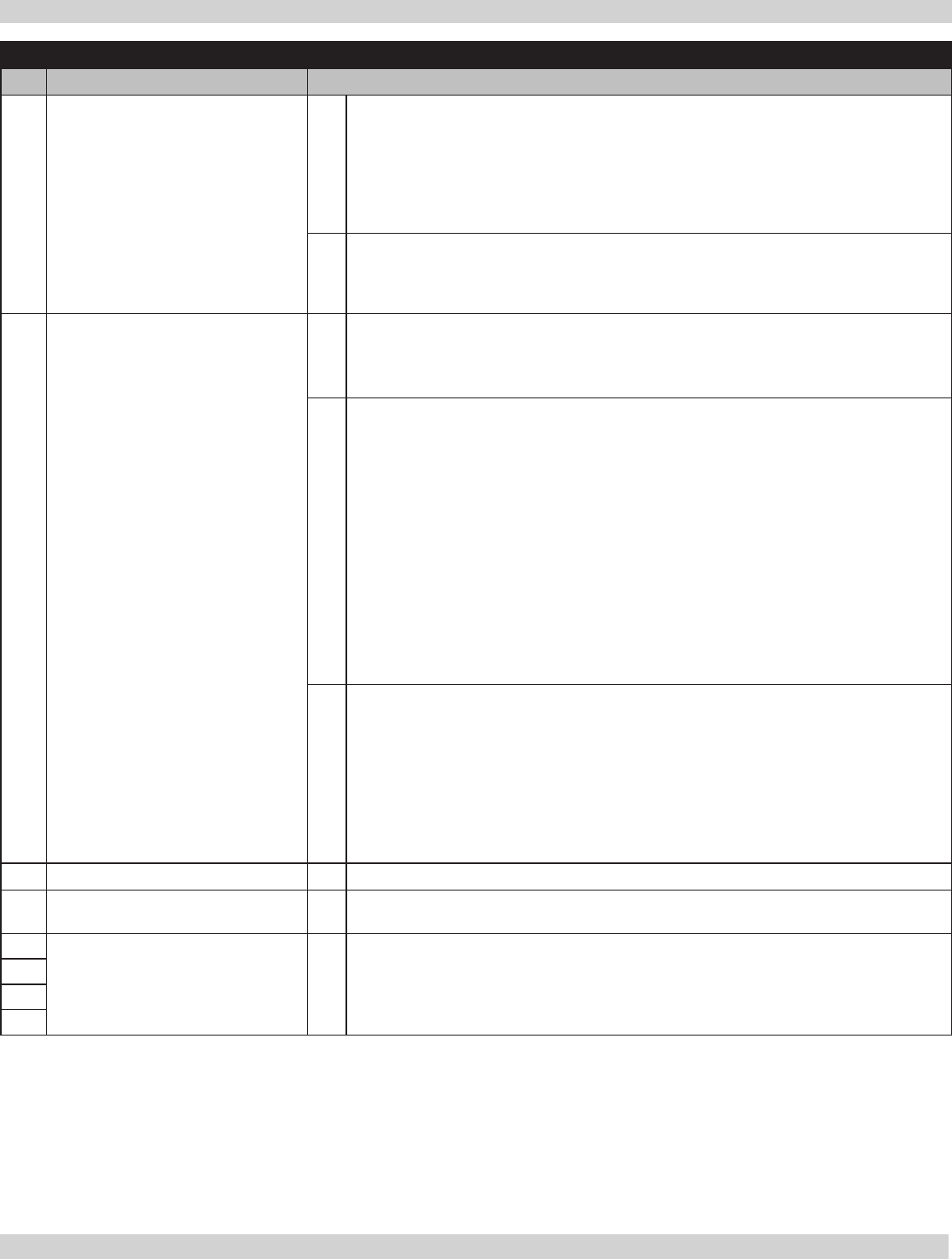

HARD LOCKOUT (Display ashes rst digit “E” and last two digits (code))

Code Reason For Hard Lockout Corrective Actions (pressing RESET should restart boiler immediately):

00 Flame detected on startup.

1

Burner may be operating too hot due to incorrect combustion. Inspect ame during

operation following procedure in this manual. If ame is acceptable at both high and

low re, go to step 2. If ame is not acceptable:

For propane boilers, verify propane orice is correct and properly installed. Obtain

and install propane orice if necessary.

For correct orice propane or natural gas boilers, replace gas valve if burner glows

excessively.

2

Look into the burner inspection window after the boiler shuts down. If ame is still

present, gas valve may be leaking. Replace gas valve. BEFORE replacing valve,

check gas line pressure coming to boiler. Pressure must not exceed 13” w.c. or valve

damage could occur.

02 Ignition failed through 5 attempts.

1

If no ignition spark occurs:

Check ignition electrode cable, electrode connector, and connections.

Inspect ignition electrode cable and electrode for insulation damage.

Check ground lead from ground terminal strip to heat exchanger access cover.

2

If spark occurs, but no ame:

Verify manual gas valve in boiler is open.

Verify plastic line from gas valve to air inlet elbow is connected to gas valve and

elbow, and line is unobstructed with no kinks.

Check incoming gas pressure.

Verify gas lines are free of obstruction and purge gas lines of air if necessary.

Verify ue gas vent and air supply piping are correctly installed, in good condition,

and free of obstructions.

Check voltage to gas valve (approx. 19-21 VDC (24 vrac) during ignition attempt).

Check gas meter to verify gas ows when gas valve is activated.

Remove and inspect/clean ignition electrode. Clean white oxides if necessary and

replace ignition electrode if in poor condition or unable to be cleaned.

Disconnect gas valve from Venturi. Inspect Venturi gas line to verify there are no

obstructions. Replace gas valve.

Check for possible ue gas recirculation at vent/air terminations or inside boiler

housing.

If gas valve is powered, gas ows when activated, and above steps have been

veried, replace gas valve and retry.

3

Flame occurs but ame signal too low (less than 3 vdc between X1-5 and ground):

Inspect ame at both low and high re rates. Inspect and clean burner if necessary.

Replace burner if not in good condition.

Check gas ow rate at gas meter with boiler at high re. If input is not within about

10% of boiler rating, replace gas valve. (Length of the vent/air piping will affect

boiler ring rate, with longer piping causing lower inputs.)

Check ground wire and connections from ground terminal screw to X1-6 terminal on

wiring harness. Use ground continuity meter to verify good ground path.

Follow procedure to inspect and clean ignition electrode. Replace ignition electrode if

necessary.

If above does not correct problem, replace control module.

03 Gas Valve Disconnected. 1 Verify gas valve connection.

04 Voltage lost after lockout occurred. 1

Control module will only restart with manual reset, even after power loss (but the

error code information is lost).

05

Internal control failure. 1 Reset control and retry. If problem persists, replace control module.

06

07

08

9 - TROUBLESHOOTING