Operating instructions

12

Proper wiring procedures.

Installation

Proper wiring prevents electrical noise

Electrical noise can produce undesirable effects on

electronic control circuits, thereby affecting

controllability. Electrical noise is generated by

electrical equipment, such as inductive loads, electric

motors, solenoid coils, welding machinery, or

fluorescent light circuits. The electrical noise or

interference generated from these sources (and the

effect on controllers) is very difficult to define, but

the most common symptoms are erratic operation or

intermittent operational problems.

Most noise problems can be prevented by using

proper wiring practices and techniques to prevent

coupling or inducing of electrical interference into

control circuits. The following simple wiring

practices should minimize interaction of noise and

controls:

• Connect humidifier and control cabinets to a

code-approved earth ground.

• Separate the line voltage wiring from low

voltage control circuit wiring when routing

electrical wiring inside the control cabinet.

• Use separate electrical conduits for line and low

voltage control wiring from the humidifier to

humidity sensors, airflow switches, etc.

More on next page . . .

Installation:

Wiring techniques

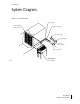

Figure 12-1: Control cabinet knockout locations for power and control

Knockouts

for heater wiring

(for VAPORSTREAM

®

, STS

®

, LTS

®

)

Knockouts for

power wiring

CAUTION: When making holes and

knockouts in the control cabinet, protect

all internal components from debris, and

vacuum out cabinet when finished.

Failure to comply with this warning may

damage sensitive electronic components

and void the DRI-STEEM warranty.

Knockouts

for control

wiring

OM-762