Specifications

Power Train Testing and Adjusting 46

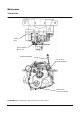

7. Check lubrication pressure at pressure tap (7) with

the transmission in neutral.

a. If lubrication pressure is low, see Problem: Low

lubrication pressure in Troubleshooting.

b. If lubrication pressure is high, see Problem:

High lubrication pressure in Troubleshooting.

8. Check converter charge (inlet) pressure at pressure

tap (3) with the transmission in neutral.

a. If converter charge pressure is low, see

Problem:

Low converter charge pressure in

Troubleshooting.

b. If converter charge pressure is high, see

Problem:

High converter charge pressure in

Troubleshooting.

9. Check converter outlet or cooler inlet pressure at

pressure tap (2) with the transmission in neutral.

a. If the pressure is low, see Problem:

Low converter outlet or cooler inlet pressure in

Troubleshooting.

b. If the pressure is high, see Problem:

High converter outlet or cooler inlet pressure in

Troubleshooting.

NOTE: Do not activate the inching pedal when

pressure checks are made. Check for the pressures

as shown in Transmission Pressure Chart in the

order that follows:

Converter Stall Test

NOTE: Make sure that the transmission oil is at the

correct temperature for operation before tests are

made.

The converter stall test is a test to check engine power.

It can also be used to locate a problem in the

transmission or torque converter when the condition of

the engine is known. An engine, which does not have

correct performance, will give an indication of a stall

speed that is not correct. If the engine performance is

correct and the stall speed is not correct, the problem

in the converter or transmission can be found with this

test.

NOTE: To check the engine performance, see the

respective engine module. This test checks the

maximum RPM that the engine, at full throttle, can turn

the converter with the turbine held stationary. To hold

the converter turbine, engage the brakes with the

transmission in FORWARD or REVERSE.

The drive wheels must not turn during the stall test.

Put a heavy load on the forks. Also put the truck in

position against a solid object that will not move (such

as a loading dock). When the tests are made, the

wheel brakes must be engaged with the left foot. The

accelerator pedal can be operated with the right foot.

WARNING

Make tests in a clear level area only. There must

be one operator. Keep all other personnel away

from the lift truck. Check the operation of the

brakes before the tests are made.

Check the high idle setting before the stall test is made.

Set the high idle to the specification, as given in the

respective engine module.

NOTE: Make sure that the transmission oil is at the

correct temperature for operation before tests are

made.

1. Connect a tachometer to the engine. Start the

engine. Engage the wheel brakes with the left foot.

2. Put the transmission control lever in FORWARD

and push the accelerator pedal down completely

with the right foot. Read the RPM on the

tachometer, then release the accelerator pedal.

Transmission Pressure Chart

Low idle 2000 rpm

Shift position - Neutral

Main Line

830 to 1,030, kPa

(120 to 150psi)

895 to 1,100,kPa

(130 to 160psi)

Clutch

0 kPa

(0 psi)

0 kPa

(0 psi)

Lubrication

14 to 70 kPa

(2 to 10 psi)

240 to 345 kPa

(35 to 50 psi)

Converter Chage

70 to 140 kPa

(10 to 20 psi)

590 to 795 kPa

(85 to 115 psi)

Converter Outlet

or Cooler Inlet

25 to 55 kPa

(4 to 8 psi)

250 to 400 kPa

(36 to 58 psi)

Shift position – Forward or Reverse

Main Line - -

Clutch

725 to 860 kPa

(105 to 125 psi)

725 to 965 kPa

(105 to 140 psi)

Lubrication - -

Converter Chage - -

Converter Outlet

or Cooler Inlet

-

-

-

-