Specifications

Power Train Testing and Adjusting 44

Transmission Pressure Test

Tools Needed

Pressure Gauge Group 1

WARNING

To prevent personal injury, when the transmission

is tested, move the truck to a clear area, that is

level. Keep all other personnel away from the lift

truck. Use lifting equipment or a save method to

lift the front of the lift truck until the drive wheels

are off the floor. Put wood blocks or jack stands of

the correct capacity under it to hold it in this

position while pressure tests are performed.

When the transmission tests are made, the

transmission oil must be at the correct level. The

pressure given in the chart are taken with the

transmission oil temperature at 49 to 71°C (120 to

160°F). If the oil temperatue is lower than 49°C

(120°F) the oil pressure will be higher than that shown.

If the oil temperature is higher than 71°C (160°F), the

pressure will be lower than that shown.

Raise the front of the lift truck off the floor. Put wood

blocks or jack stands of the correct capacity under it to

hold it in this position while pressure tests are

performed.

WARNING

Before any pressure tap plugs or connections are

removed, the engine must be stopped with the

transmission controls in NEUTRAL. This will

release hydraulic pressure in the transmission.

For more identification of transmission problems, the

pressures that follow can be checked.

a. Pump pressure in neutral.

b. Forward clutch pressure in forward.

c. Reverse clutch pressure in reverse.

d. Converter charge pressure in neutral.

e. Converter outlet or cooler inlet pressure in neutral.

f. Lubrication pressure in neutral.

Most problems in the hydraulic circuit can normally be

found when the pump pressure is checked. If more

information is necessary, gauges can be installed at

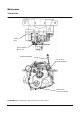

each pressure tap location. Locations of the pressure

taps and procedures for testing are given as follows. If

any of the pressures are not correct, refer to

Troubleshooting For Problems and Probable Causes.

1. Be sure the transmission control adjustments are

correct before tests are made.

See Inching Pedal Adjustment in Testing and

Adjusting.

2. Install a tachometer to the engine to show engine

speed during the test.

3. Put a thermistor probe in place of the dipstick in the

transmission oil reservoir.

4. Remove each of the following pressure tap plugs in

the order shown and install the 0 to 2050 kPa (0 to

300 psi) pressure gauge. After the pressure check

is done, remove the gauge and install the plug

again.

5. Check pump pressure with the transmission in

neutral at pressure tap (6) on the valve body first. If

it is not correct, then check pump pressure at

pressure tap (1) on the bearing plate.

a. If the pressure is low at pressure tap (6), but

correct at pressure tap (1), there could be an oil

line restriction or a defective inching valve.

NOTE: Pump pressure should be checked at

pressure tap (6) first because pressure tap (6) is

easier to get to than pump pressure tap (1) on the

bearing plate. If pump pressure is correct at

pressure tap (6), it will be correct at pressure tap

(1) also.

b. If the pressure is low at both locations, see

Problem: Low pump pressure in Troubleshooting.

NOTE: Pump pressure is adjusted by adding or

removing shims in the D700296 Plug. The plug is

located in the main relief valve on the valve body.

6. Check clutch pressure as follows:

a. Check forward clutch pressure at pressure tap

(4) with the transmission in forward. If the

pressure is not correct, see Problem: Low

forward clutch pressure in Troubleshooting.

b. Check reverse clutch pressure at pressure tap

(5) with the transmission in reverse. If the

pressure is not correct, see Problem: Low

reverse clutch pressure in Troubleshooting.