Service manual

Table Of Contents

G420F(FE) Service Manual Chapter 3. Engine Mechanical System 96

Disassembly

1. Remove the cylinder head assembly.

NOTE: Put an identification mark on the connecting

rod and cap before disassembly to refer to the

original position and direction.

2. Remove the oil pan and remove the oil screen.

3. After removing the connecting rod cap, remove

the piston and connecting rod assembly from the

cylinder. Arrange the connecting rod bearing in

cylinder number order.

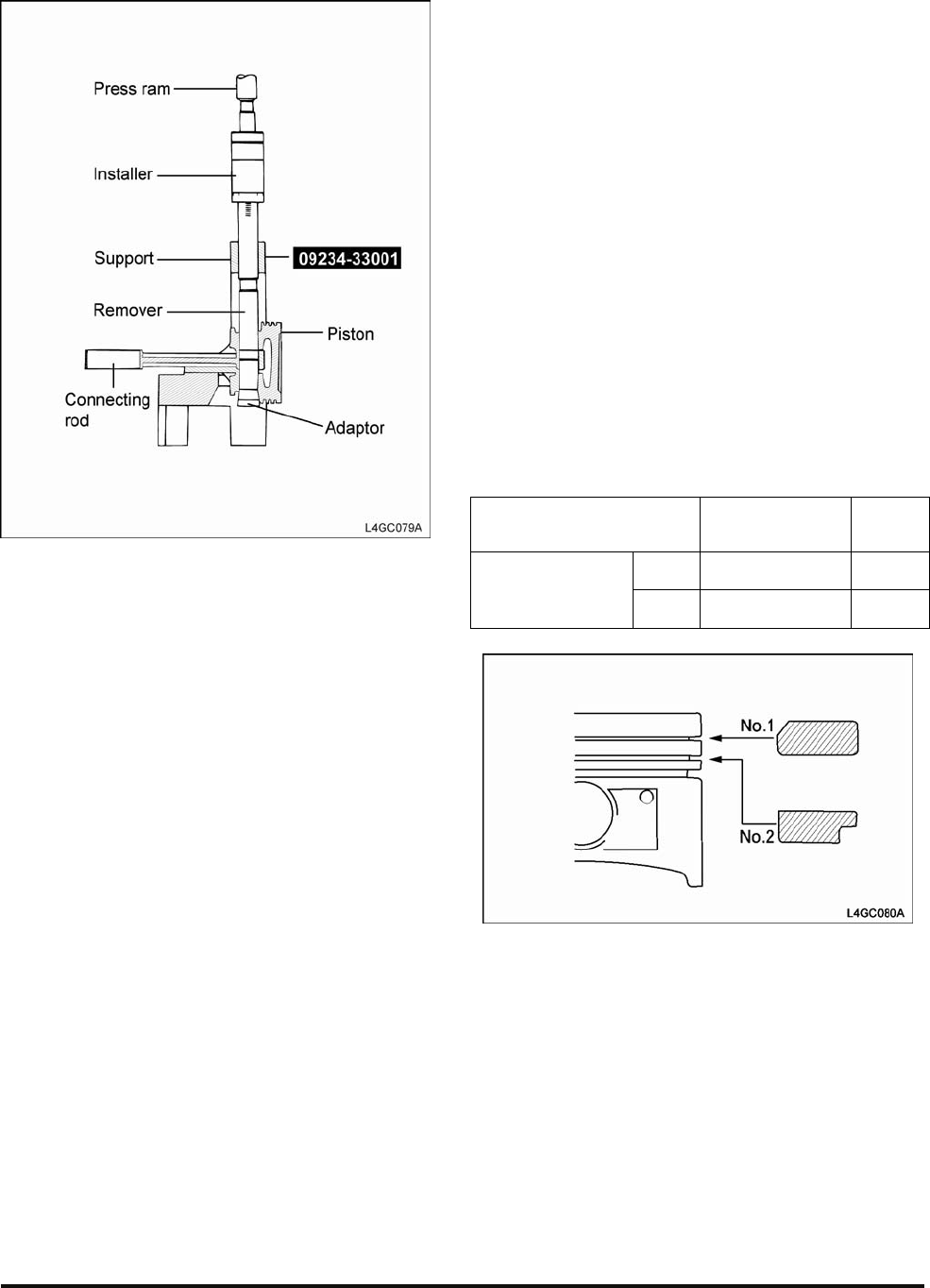

4. Using the special tool piston pin setting tool

(09234-33001), disassemble the piston from the

connecting rod as below.

1) Remove the piston ring.

2) When placing the assembly on a press, face

the front mark on the piston upward.

3) Using the press, remove the piston pin.

Inspection

Piston and Pistonpin

1. Check the piston for scratch, wear, etc. and

replace it if necessary.

2. Check the piston ring for break, damage and

abnormal wear and replace it if necessary. When

replacing the piston, the ring should be replaced

also.

3. Check that the piston pin is inserted in the piston

hole and replace the piston and pin if necessary.

Piston should be smoothly pressed at normal

room temperature.

Piston Ring

1. When measuring the side clearance of piston ring,

if the measured value is out of the limit, insert a

new ring to the ring groove and re-measure the

side clearance.

Item

Specified

value

Limit

No.1 0.04 ~ 0.08mm 0.1mm

Side clearance

of piston ring

No.2 0.03 ~ 0.07mm 0.1mm

2. To measure the end gap of piston ring, insert the

piston ring to the cylinder bore. At this time,

smoothly insert the ring to the piston so as to

place the ring and cylinder wall to right position.

After this, smoothly insert the ring to the piston.

And then, pull out the piston upward and measure

gap using a feeler gauge. When the gap exceeds

the limit, re-place the piston ring.