Service manual

Table Of Contents

G420F(FE) Service Manual Chapter 3. Engine Mechanical System 91

Disassembly

1. Remove the timing belt train, front case, flywheel,

cylinder head assembly, and oil pan.

2. Remove the rear oil seal.

3. Disconnect the connecting rod cap.

4. Remove the main bearing cap. (Arrange it in

order)

5. Remove the crankshaft.

6. Disassemble the crankshaft position sensor wheel.

NOTE: Put an identification mark on the main

bearing cap to refer to the original position and

direction.

Inspection

1. Crankshaft

1) Check the oil hoe for clogging as well as

crankshaft journal pin for damage, uneven wear

and crack. Repair or replace parts if necessary.

2) Inspect out of circularity of the crankshaft

journal taper and pin.

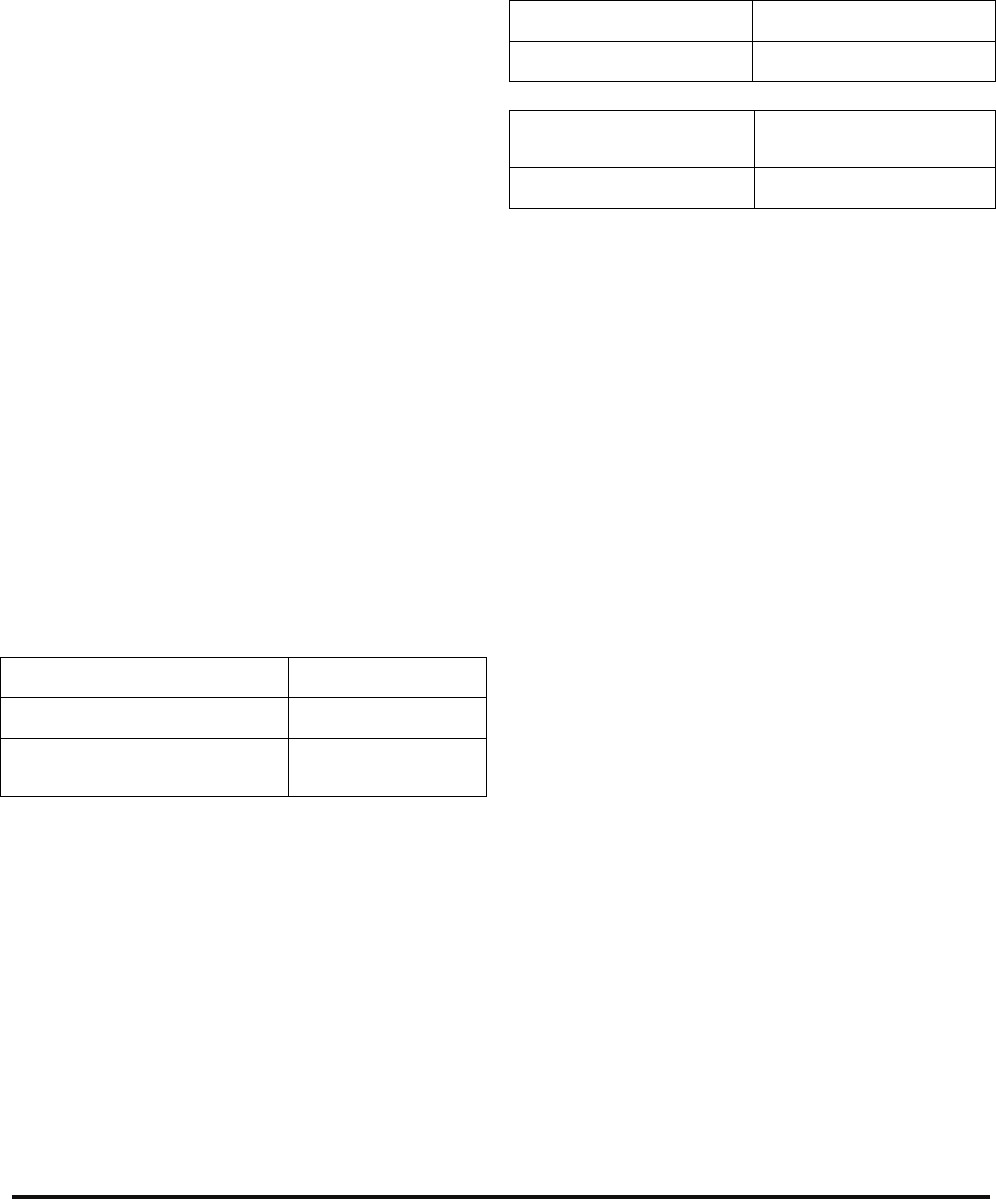

Crankshaft journal O.D 57mm

Crank pin O.D 45mm

Out of circularity of crankshaft

journal pin

0.01mm or less

2. Main bearing and connecting rod bearing

Visually inspect each bearing for scratch, melting,

sticking, and fault contact and replace the bearing

if necessary.

3. Measuring oil clearance

1) Measure O.D of the crankshaft journal and pin.

2) Measure diameter of the crankshaft bore and

connecting rod bore.

3) Measure the thickness of the crankshaft and

connecting rod bearing.

4) Calculate clearance by subtracting O.D of the

journal pin and thickness of the bearing from

diameter of the bore.

Journal oil clearance 0.028 ~ 0.048mm

Pin oil clearance 0.024 ~ 0.044mm

Main bearing cap bolt

2.7 ~ 3.3kg·m+

(60°~ 65°)

Connecting rod cap bolt 5.0 ~ 5.3kg·m

4. Oil seal

Check the front and rear oil seal and replace it

with new parts if necessary.