Service manual

Table Of Contents

G420F(FE) Service Manual Chapter 3. Engine Mechanical System

111

Class Piston outer diameter Size code

A

81.97~81.98mm

(3.2271~3.2275in.)

A

B

81.98~81.99mm

(3.2275~3.2279in.)

None

C

81.99~82.00mm

(3.2279~3.2283in.

C

8. Select the piston related to cylinder bore class.

Clearance

0.02 ~ 0.04 mm (0.00078 ~ 0.00157in.)

Boring cylinder

1. Oversize pistons should be selected according to

the largest bore cylinder.

Identification Mark Size

0.25 0.25 mm (0.010in.)

0.50 0.50 mm (0.020in.)

NOTE: The size of piston is stamped on top of the

piston.

2. Measure the outside diameter of the piston to be

used.

3. According to the measured O.D., calculate the

new bore size.

New bore size = Piston O.D + 0.02 to 0.04 mm

(0.0008 to 0.0016 in.) (clearance between piston

and cylinder) -0.01 mm (0.0004in.) (honing margin.)

4. Bore each of the cylinders to the calculated size.

CAUTION

To prevent distortion that may result from

temperature rise during honing, bore the

cylinder holes in the firing order.

5. Hone the cylinders, finishing them to the proper

dimension (piston outside diameter + gap with

cylinder).

6. Check the clearance between the piston and

cylinder.

Standard: 0.02-0.04 mm (0.0008-0.0016 in.)

NOTE: When Boring The cylinders, finish all of the

cylinders to the same oversize. Do not bore only one

cylinder to the oversize.

Piston and Rings

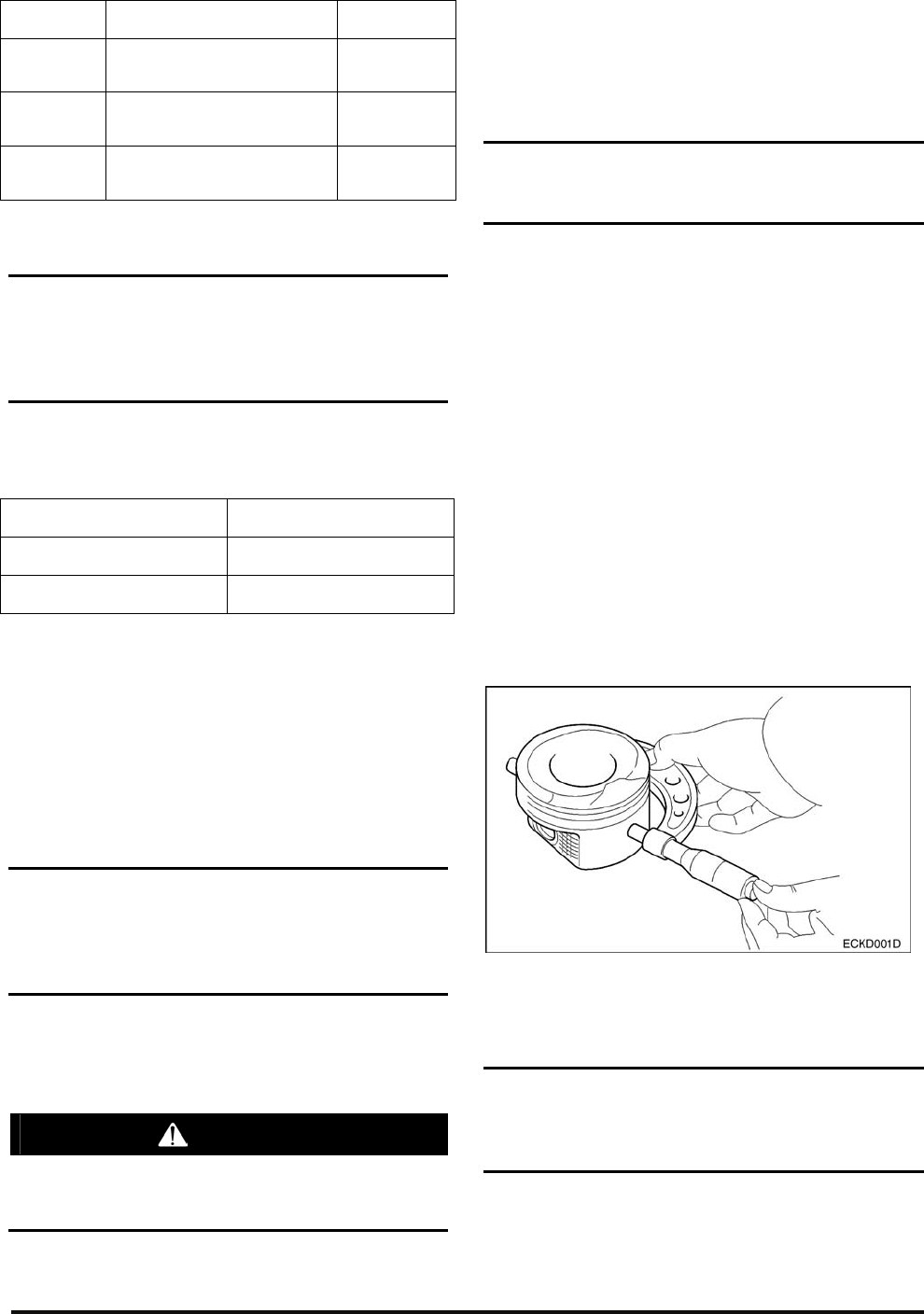

1. Clean piston

1) Using a gasket scraper, remove the carbon

from the piston top.

2) Using a groove cleaning tool or broken ring,

clean the piston ring grooves.

3) Using solvent and a brush, thoroughly clean the

piston.

NOTE: Do not use a wire brush.

2. The standard measurement of the piston outside

diameter is taken 47 mm (1.85in.) from the top

land of the piston.

Standard diameter

81.97 ~ 82.00 mm(3.2272 ~ 3.2283in.)